Modvion, a Swedish wood technology firm, is pioneering the construction of the world’s tallest wooden wind turbine tower, standing at 105 meters in height. The innovative tower will be erected in Skara, Sweden, and commissioned for Varberg Energi, a local energy provider. Danish manufacturer Vestas will equip the wooden tower with a 2MW turbine, marking a debut for this combination. The entire construction, inclusive of turbine blades, will soar to an impressive 150 meters.

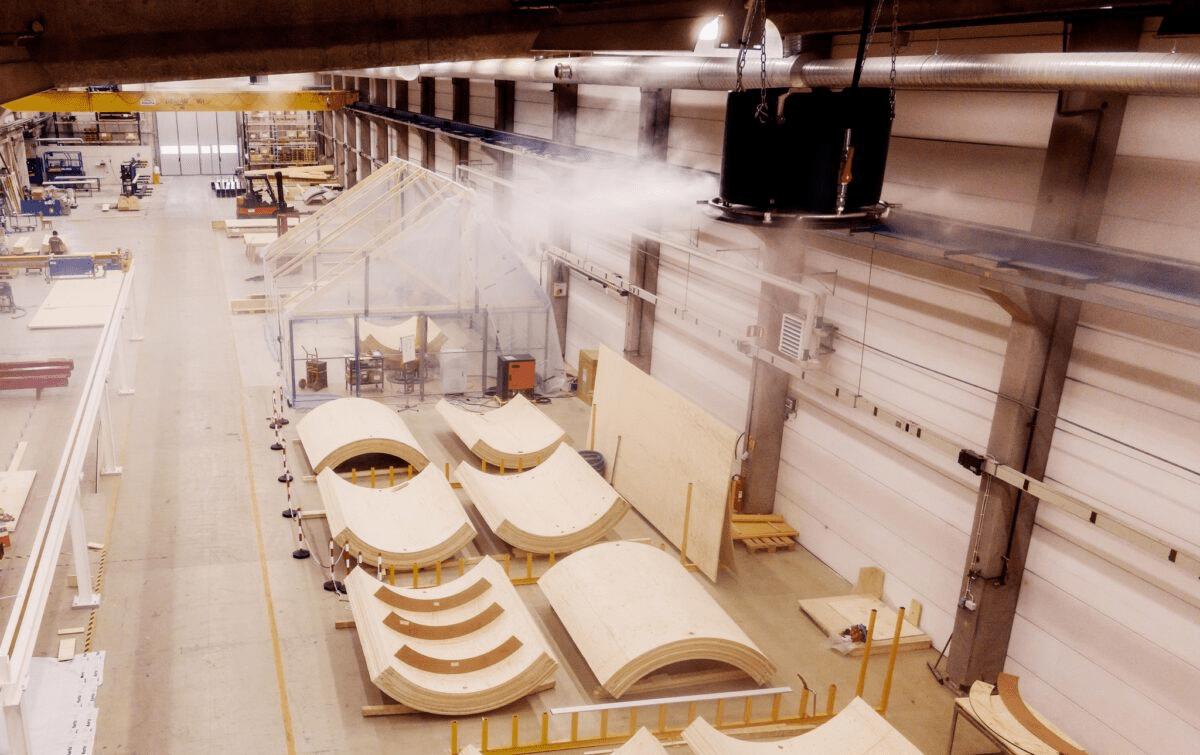

Crafted from laminated veneer lumber, the tower’s wood modules boast a superior strength-to-weight ratio compared to traditional steel. This cutting-edge material is essentially massive layers of wood glued together, offering durability while being 30% lighter than steel. The modular design of the tower not only reduces transport costs but also simplifies logistics due to its compatibility with standard roads. An eco-friendly highlight is the tower’s carbon-negative footprint, with wood naturally absorbing atmospheric carbon. In comparison, a steel tower of similar stature emits around 1,250 tonnes of CO2, while Modvion’s wooden design reduces this by a staggering 90%.

The question arises: Can this wooden marvel endure as long as its steel counterparts? Laminated Veneer Lumber, often dubbed nature’s carbon fiber, offers strength comparable to steel without the added weight. To ensure longevity, the tower is sealed with a thick, waterproof paint, ensuring a controlled air volume inside, combatting humidity. Contrary to initial fire concerns, the dense nature of the logs used in Modvion’s design presents significant fire resistance. Modvion’s ingenious approach involves stacking 16 to 24-meter tall cylinders, reminiscent of building blocks, for tower assembly. Sourcing its raw material, Scandinavian spruce, presents no sustainability concerns as re-growth outpaces logging. Once functional, the tower will possess the capability to power approximately 500 households.

Similar Posts

Modvion’s CEO, Otto Lundman, envisions this as the dawn of a green industry revolution, with wood enabling taller towers, reduced costs, and enhanced wind power efficiency. Richard Cochrane, an industry expert from the University of Exeter, sees potential in wood-based modular designs for future wind energy advancements. One of the steel industry’s significant downsides is its contribution to 8% of global CO2 emissions, making wooden alternatives even more appealing. Another environmental advantage of wooden towers is their potential reuse as building materials post their operational life of about 25-30 years.

Modvion’s prototype, a 30m wooden turbine, has already been successfully constructed in Björkö, Sweden. The company’s ambitious roadmap includes two additional projects, hinting at even larger wooden wind turbines by 2025. Financial backing for this endeavor comes from the Swedish Energy Agency, the Västra Götaland region, and the EU program Horizon 2020 EIC Accelerator. Meanwhile, in Europe, Finnish manufacturer Stora Enso collaborates with German startup Voodin Blade Technology to craft sustainable wooden wind turbine blades. Stora Enso’s partnership with Modvion sparks speculation about a near-future wind turbine predominantly made of wood. The global wind energy market’s trajectory suggests a demand for sustainable, taller, and more efficient turbines. With its wooden wind turbine, Modvion stands at the forefront of this eco-friendly, technological evolution.