Stanford University and King Fahd University of Petroleum and Minerals researchers have developed a device that produces ammonia from air using wind energy. This innovation aims to replace the Haber-Bosch process – a century-old method that currently produces ammonia by combining nitrogen and hydrogen under high pressure and temperature conditions.

The traditional ammonia production process consumes 2% of global energy and generates 1% of annual carbon dioxide emissions due to its reliance on natural gas. Agriculture contributes about one-third of all greenhouse gas emissions, according to the UN Environment Programme.

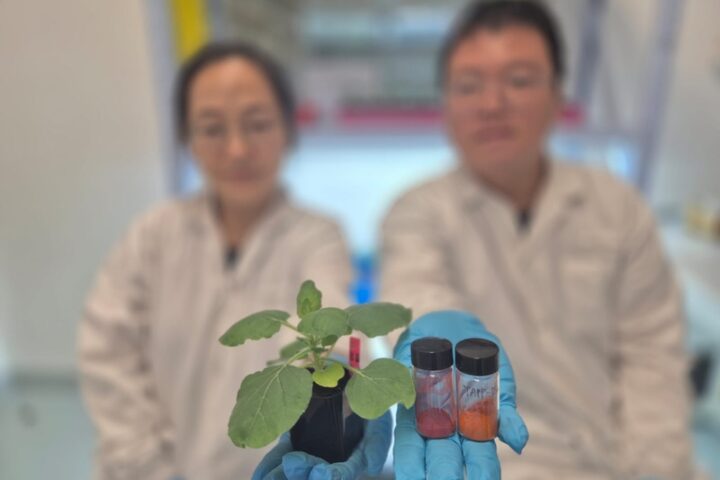

The research team, led by Richard Zare, the Marguerite Blake Wilbur Professor in Natural Science at Stanford, has successfully demonstrated the technology outside laboratory conditions. “This breakthrough allows us to harness the nitrogen in our air and produce ammonia sustainably. It’s a significant step toward a decentralized and eco-friendly approach to agriculture,” Zare stated.

Technical Implementation

The device operates by drawing air through a mesh coated with catalysts. The team studied various environmental factors including humidity, wind speed, salt levels, and acidity to optimize ammonia production. They tested combinations of iron oxide and acid polymers containing fluorine and sulfur to determine optimal catalyst conditions.

Xiaowei Song, the study’s lead author and chemistry research scientist at Stanford, noted: “This approach significantly reduces the carbon footprint of ammonia production.” The process generates ammonia at room temperature and standard atmospheric pressure without requiring external voltage sources.

Laboratory tests demonstrated that the system, when equipped with a microporous stone filter and water recycling mechanism, produced sufficient ammonia concentration for greenhouse plant fertilization within two hours.

More Stories

Market Readiness and Practical Applications

According to study co-author Chanbasha Basheer of King Fahd University of Petroleum and Minerals, the device requires two to three years of development before market introduction. The researchers plan to scale up production using larger mesh systems.

The technology’s potential extends beyond fertilizer production. Ammonia’s higher energy density compared to hydrogen gas makes it an efficient carrier for renewable energy storage and transportation, potentially benefiting shipping and power generation sectors.

The study, published in Science Advances on December 13, received funding from the U.S. Air Force Office of Scientific Research and King Fahd University of Petroleum and Minerals.

As envisioned by the researchers, this technology could be integrated into irrigation systems, enabling farmers to generate fertilizer directly from the air. The researchers plan to use increasingly large mesh systems to produce more ammonia, as stated by Basheer: “There is a lot of room to develop this.”