Industrial design student, studying in Izmir University of Economics, Alara Ertenu is a bio designer and material researcher, working with food waste. She has developed a packaging solution for soap made from peapods and artichoke waste. She has named it PACKIOLI, which was on show as part of Isola Designs Materialised Exhibition in Dutch Design Week 22 held in Irisbuurt, Eindhoven from 22nd to 30th October.

Made of artichoke leaves or peapods, the water resistant bio-packaging can be used for commercial soaps & are 100% biodegradable. It is made from materials especially sourced from the west of Turkey and serves as a local-source alternative to soap packaging. It can even be easily used for multipacks which come in a golden-brown colour, and is designed to offer a less polluting alternative to commonly used plastic soap packaging. The project aims to address the pressing environmental issue of single-use plastic consumption while simultaneously reducing food waste.

The PACKIOLI Story

PACKIOLI is born with the awareness of the enormous numbers of local food waste and its potential to replace our every-day products to help to achieve sustainability starting from where we live.

Uses of PACKIOLI

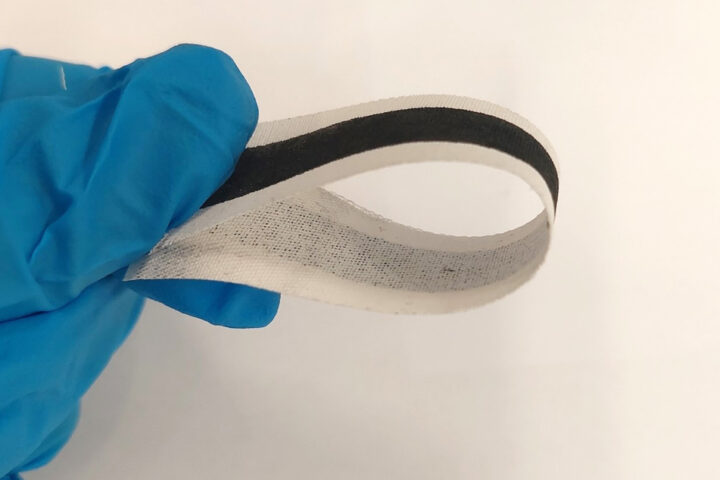

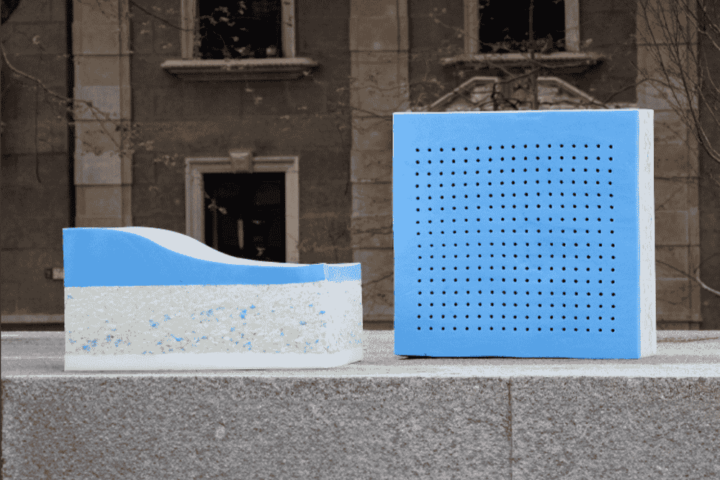

The material can be used to wrap soaps of different shapes and sizes. Translucent and speckled in appearance, Packioli can be used to pack soaps of different shapes and sizes and is designed to biodegrade completely within 15 days. Users can keep Packioli in a dry place away from water to preserve it longer, or rest it on a soap dish and allow it to melt away in contact with water inorder to dispose of it.

“Packioli is resistant to humidity and water for up to one week, which ensures that it remains intact for 10 to 15 days if there isn’t any contact with human skin under water pressure,” Alara said.

The Goal.

To eliminate the plastic packaging of the soaps and at the same time meet the hygiene, logistic and endurance needs of the commercial soap brands and businesses.

How It’s Made.

PACKIOLI comes with two different main local waste used as ingredients: Artichoke leaves and peapods. To elaborate further, it is made out of ‘Artichoke leaves Bioplastic’ and ‘Peapod Bioplastic’ which are durable, printable and flexible.

The Problem.

According to Zero Waste Week, the global cosmetics industry produces over 120 billion units of packaging every year, most of which is non-recyclable and ends up in landfill, or worse yet, the ocean. On average 80% of each leaves and stems of artichokes goes to waste.

The Material/ The Design – The Solution.

PACKIOLI can compete with traditional packaging materials which are currently used in the market with sealed edges – water, dirt and dust resistant and its compatibility with manufacturing methods.

● It is flexible which can be formed in any shape.

● It has a moisturiser property.

● Dyed with natural colours from plants – beetroot and turmeric, without any chemicals.

● A surface finishing that is suitable for printing/ bioprinting.

Thus in response, designers and brands are increasingly looking to create alternatives to plastic cosmetic packaging. Among them is sustainable packaging brand Notpla, which used seaweed leftover from its own production processes to create a kind of paper soap packaging.