Varda Space Industries, a California-based startup founded by former SpaceX engineer Will Bruey and Delian Asparouhov, a principal at Founders Fund, has successfully launched the world’s first space factory. This groundbreaking initiative aims to manufacture pharmaceutical products in the unique environment of microgravity, leveraging the benefits of zero gravity to create innovative and superior quality goods. Varda’s W-Series 1 Satellite, recently deployed into orbit, will serve as the pilot spacecraft for testing the production of medical products during its space journey. The primary focus of Varda’s initial test campaign is the development of ritonavir, a prescription medicine commonly used in the treatment of HIV infection. Using microgravity, Varda intends to explore the production of pharmaceuticals, fiber optic cables, and semiconductors that may exhibit improved performance compared to their Earth-manufactured counterparts.

Varda has partnered with Rocket Lab, a prominent player in the space industry, for this project. Together, they are creating a fleet of spacecraft called Photon, which will facilitate Varda’s manufacturing and re-entry modules. These modules, weighing approximately 120 kilograms each, will be placed in the desired working orbit and maintained in position by Rocket Lab’s Photon. The collaboration also entails the integration of essential components like radios, reaction wheels, and star trackers into the Photon spacecraft, designed and built by Rocket Lab. Manufacturing products in space offers several advantages due to the absence of gravity’s influence. Research conducted by companies like Merck on the International Space Station has demonstrated that certain products, such as protein crystals, develop more perfectly in microgravity than on Earth. This breakthrough finding has enabled the production of more stable forms of critical health treatments like pembrolizumab, an active ingredient in the cancer drug Keytruda.

Similar Post

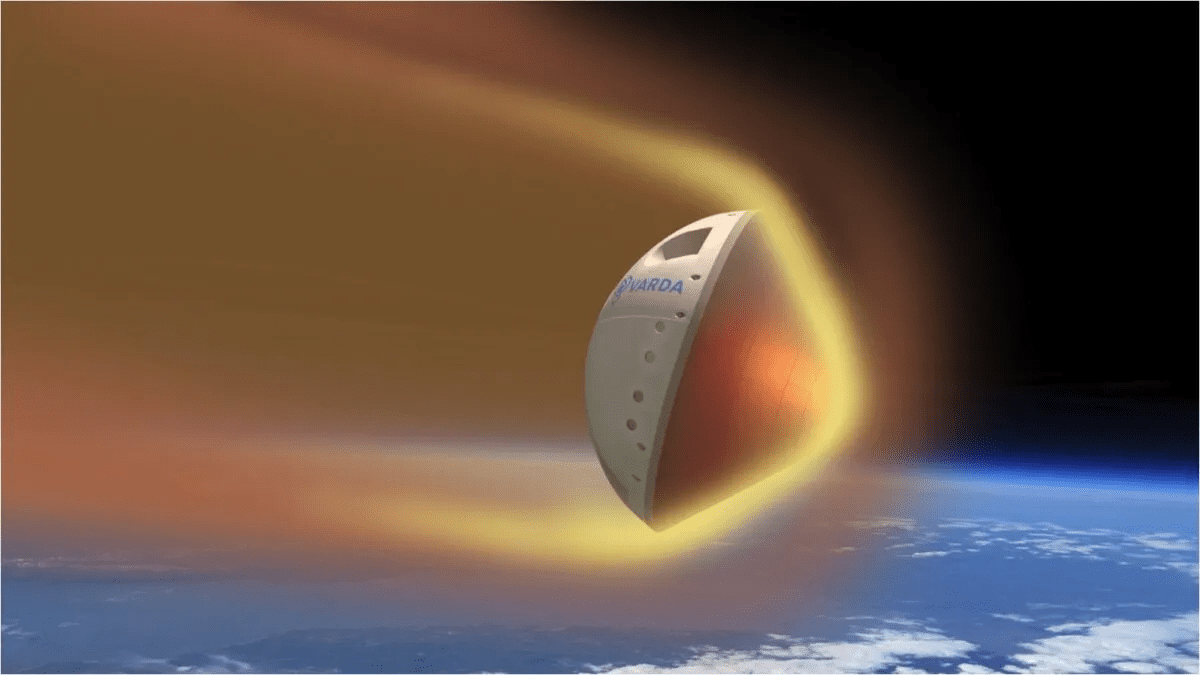

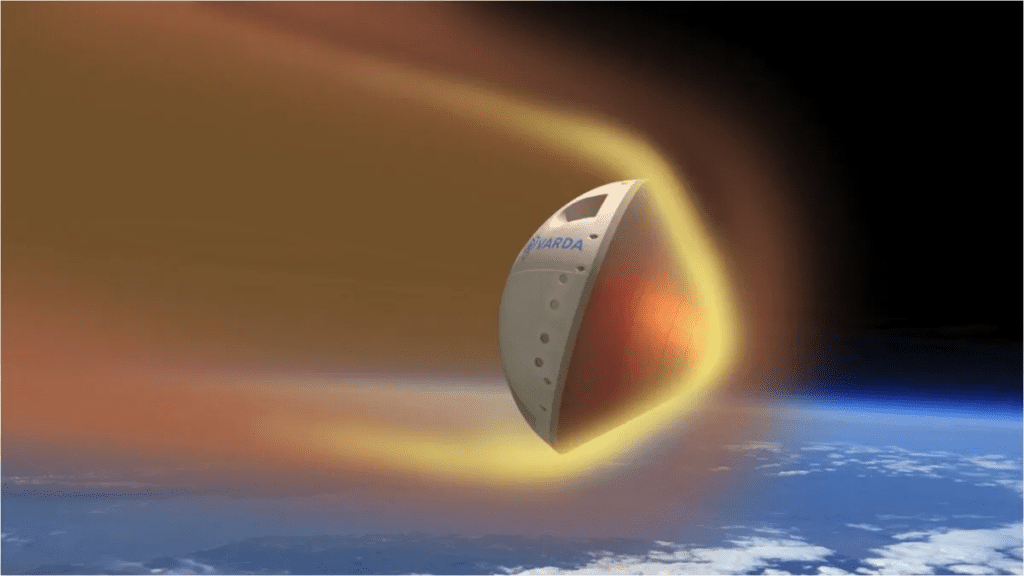

The cost-effectiveness of space manufacturing has improved significantly with the emergence of private satellite launch services provided by companies like Rocket Lab and SpaceX. Rocket Lab’s utilization of 3D printing technology has accelerated the production of large components while reducing costs. Varda has also secured lucrative contracts, like a $60-million agreement with the U.S. Air Force to employ its re-entry vehicle as a hypersonic testbed. Varda’s re-entry vehicle will travel at Mach-25 speeds as it returns to Earth’s atmosphere. While Varda’s pioneering efforts in space manufacturing are groundbreaking, it faces competition from companies like Redwire, the Space Forge, and the Exploration Company. Moreover, the increasing number of satellites and space debris orbiting the Earth raises concerns. There could be potential collisions and consequences for life on Earth. Efforts by organizations like NASA and the US Congress aim to address these challenges and mitigate potential risks.

Varda Space Industries’ vision extends beyond pharmaceuticals, with plans to explore the manufacturing of other products in the future. However, in the initial years, Varda intends to focus exclusively on pharmaceuticals due to their high value and significant market demand on Earth. By leveraging the advantages of microgravity and employing cost-effective re-entry capsules, Varda aims to revolutionize the production process and bring high-quality space-manufactured products back to Earth.