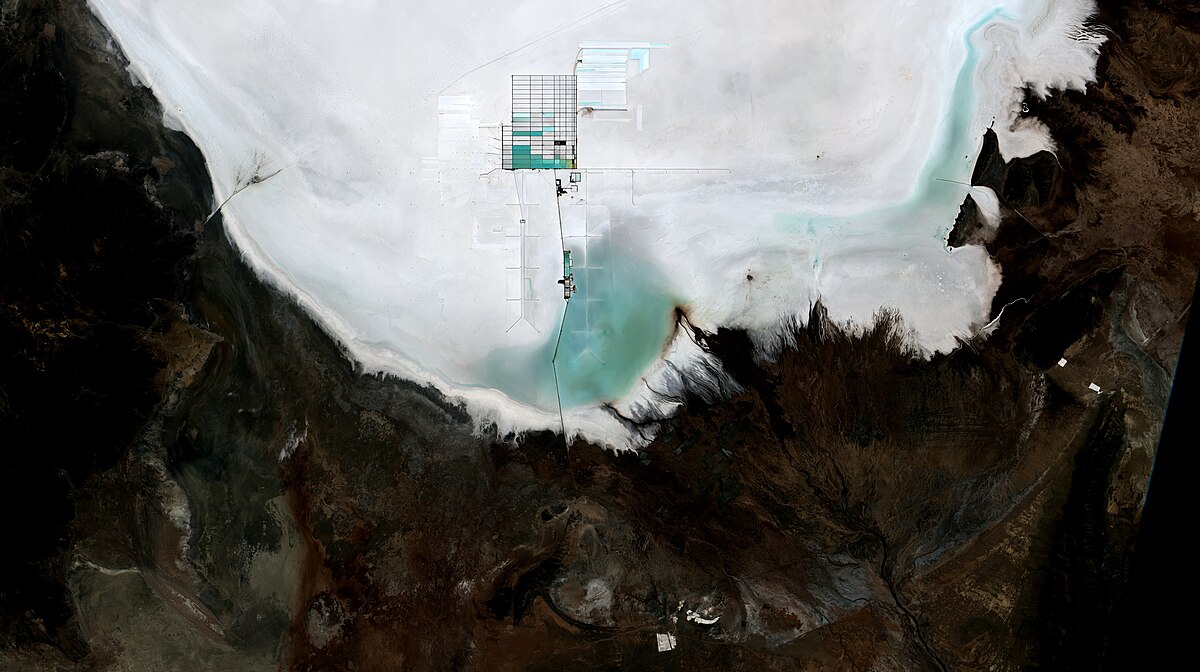

Researchers have optimized a new method for extracting lithium from widespread sources such as groundwater and “produced water” (a byproduct of hydraulic fracturing and offshore drilling). The new method promises to usher in an era of faster and more environmentally friendly lithium extraction.

Researchers from the Pritzker School of Molecular Engineering (PME) at the University of Chicago have developed a method that shows how certain iron phosphate particles can extract lithium from seawater more effectively. “Our method allows the efficient extraction of the mineral from very dilute liquids, which can greatly broaden the potential sources of lithium,” says Chong Liu, assistant professor of Molecular Engineering at the Neubauer Family.

The method isolates lithium based on its electrochemical properties, using crystalline networks of olivine iron phosphate. Due to its size, charge, and reactivity, lithium is drawn into the spaces of the iron phosphate and olivine columns, much like water soaking into the holes of a sponge. However, if the column is perfectly designed, sodium ions, also present in brackish liquids, are excluded or enter the iron phosphate at a much lower level, according to the study.

Researchers tested how variation in olivine iron phosphate particles influenced their ability to selectively isolate lithium over sodium. “When you produce iron phosphate, you can get particles that are drastically different sizes and shapes,” explains Gangbin Yan, a doctoral student and first author of the study. “In order to figure out the best synthesis method, we need to know which of those particles are most efficient at selecting lithium over sodium.”

The study details how researchers synthesized olivine iron phosphate particles using various methods, resulting in particles ranging in size from 20 to 6,000 nanometers. These particles were then grouped by size and used to build electrodes to extract lithium from a weak solution. Researchers observed that olivine iron phosphate particles that were too large or too small tended to allow more sodium into their structures, resulting in less pure extractions of this metal.

Similar Posts

The latest data from the US Geological Survey, released in January, shows that global lithium consumption increased by 27 percent in 2023, reaching 180,000 metric tons compared to 142,000 metric tons in 2022. As per Chong Liu, currently, “there is a gap between the demand for lithium and the production.” However, lithium production comes with a set of environmental impacts like soil and water degradation, habitat loss, emissions, and many others. “We think we can develop a method that reduces the environmental impact of lithium production and secures the lithium supply in this country,” concludes Liu.