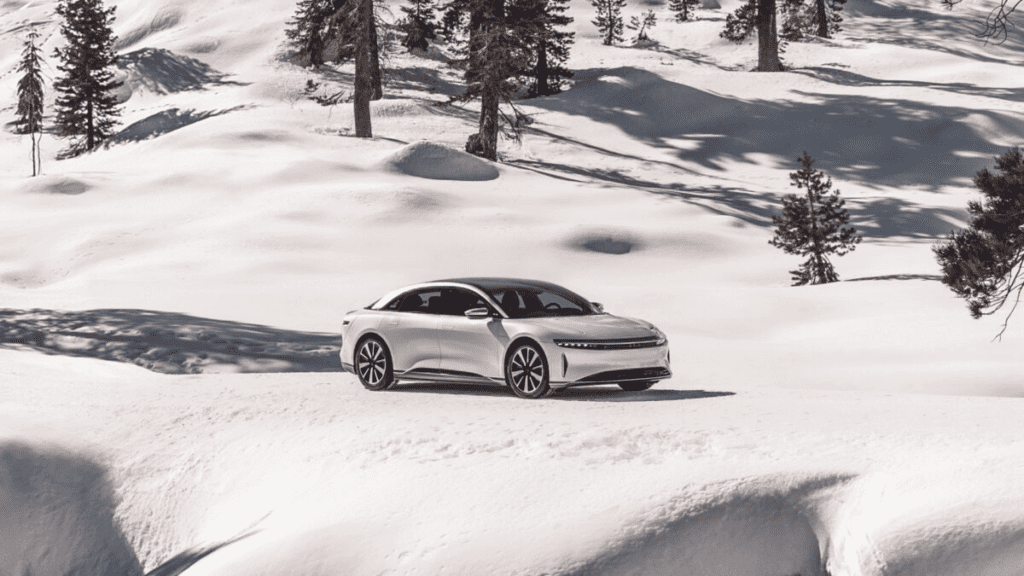

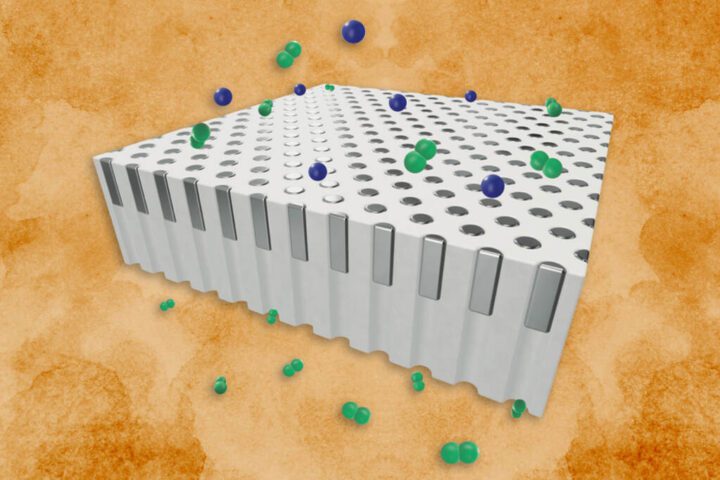

Scientists have long been aware that lithium-metal batteries have the potential to revolutionize the battery industry, particularly for use in electric vehicles (EVs). These batteries have a high capacity, low density, and are non-flammable, making them an ideal candidate for EVs. However, one major issue with lithium-metal batteries is their tendency to short circuit due to tiny fissures in the ceramic electrolyte called dendrites. The quest to understand why this occurs and develop a battery that circumvents this issue has been a significant focus of research for material scientists, and recent research has shed new light on the problem.

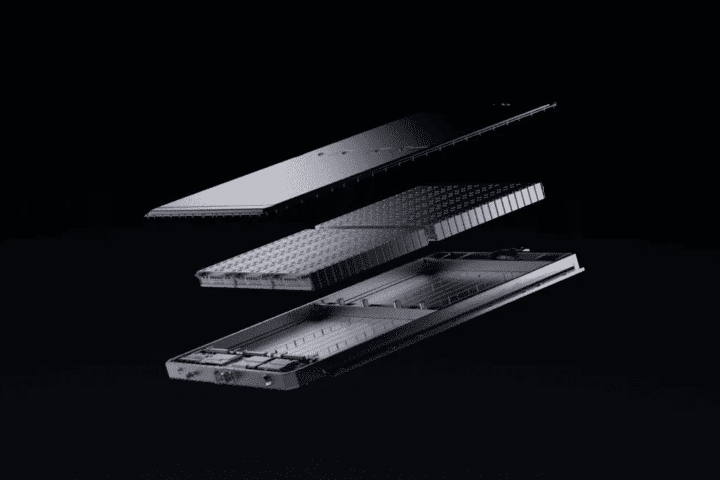

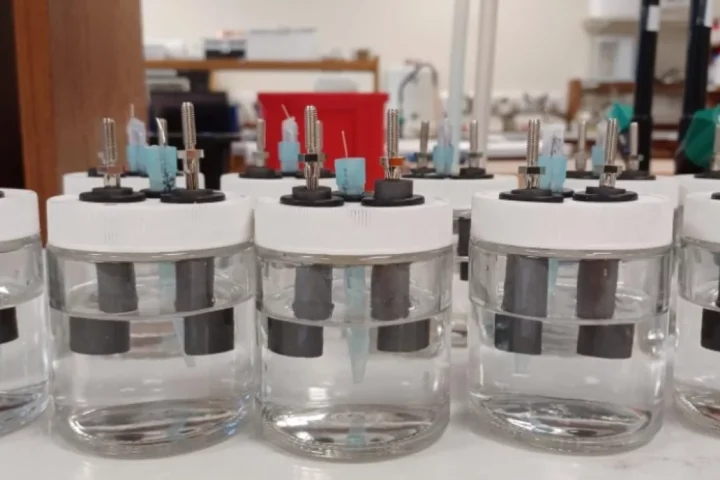

Scientists from Stanford University and the SLAC National Accelerator Laboratory conducted over 60 experiments to discover that small “nanoscopic” cracks in the ceramic solid electrolyte, which are as wide as only 20 nanometers, occur when under pressure during fast charging. These cracks allow a lithium-metal “bridge” to form between the anode and cathode, causing a short circuit.

The researchers combined an electric probe and an electrolyte to create a miniature battery to understand why lithium burrowed into certain areas and caused a short circuit. They discovered that any indentation, bending, or twisting, along with dust or other impurities introduced during the manufacturing process, increased the chances of failure. The process is similar to how potholes form in roads, where rain and snow pound into tiny imperfections, causing structural failure.

The good news is that this discovery is not a death knell for the future of lithium-metal batteries. Instead, engineers can take these findings into account when designing lithium-metal batteries, and the authors of the paper are investigating ways to strengthen the electrolyte during manufacturing and develop ways to coat the ceramic barrier to self-repair damage when it occurs.

In 2019, the same Stanford lab developed a method for lithium-metal batteries to retain 85% charge after 160 cycles, a significant improvement compared to the previously reported 30%. With this new knowledge, energy-dense, fast-charging, nonflammable lithium-metal batteries that last a long time could overcome the main barriers to their use in EVs, among other benefits.

In conclusion, the discovery of what causes lithium-metal batteries to short-circuit and fail is a significant step in improving the design of these batteries. Scientists can now work to design around the issue, or even turn the discovery to their advantage. As lead coauthor Teng Cui says, “These improvements all start with a single question: Why? Once we know that, we can improve things.”