UC Santa Cruz chemists have created a biodiesel production method using sodium tetramethoxyborate (NaB(OMe)4) at 40°C. The U.S. transportation sector burned through 3 million barrels of diesel daily in 2022. These diesel engines pumped out 10% of U.S. energy-related CO2 emissions that year. Biofuels make up a mere 6% of transportation energy use.

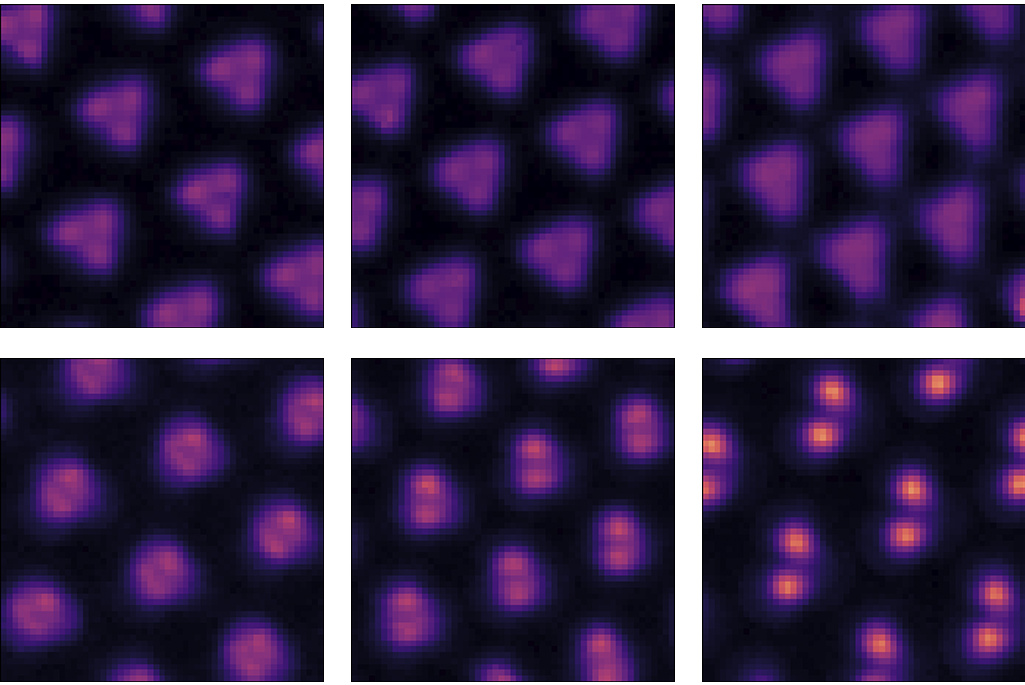

The new catalytic process runs at 40°C (104°F) – cooler than a cup of coffee. Traditional biodiesel plants crank up temperatures and pressures, eating up energy and money. NaB(OMe)4 attacks fat molecules in waste oil, transforming them into biodiesel in under 60 minutes. The biodiesel simply pours off from the byproducts.

“I started exploring this new material that we made to see if it could attack the fats in oil to help catalyze biodiesel, and it all flowed from there,” says Kevin Lofgren, lead author and Ph.D. student at UC Santa Cruz.

The team ran successful tests with waste cooking oil from fast-food restaurants, soybean oil, corn oil, olive oil, and animal fat. The process converts 85% of input oil to biodiesel. Current methods often create soap gunk that’s tough to filter out. This technique skips the soap-making hydroxide bases entirely. The glycerol byproducts solidify, making separation a pour-and-go operation.

“To make energy takes a lot of energy,” notes co-author Scott Oliver, professor of chemistry and biochemistry. “Our method uses waste oil and mild heating, compared to current petroleum refineries that are energy consuming and pollution causing.”

Palm oil biodiesel operations have cleared rainforests for plantations. This method runs on waste oil instead. The catalyst regenerates, cutting ongoing material costs. One technical hiccup remains – the water content runs slightly above industry specs. The team expects this to improve at an industrial scale.

“This new method is simple and affordable. It has the bonus of being able to regenerate the starting material,” Lofgren explains. “You can buy the most expensive ingredient once and then regenerate it, making it more cost-efficient long-term.”

The process could work anywhere with waste oil and basic lab equipment. “You don’t need to have a refinery; you can potentially use this method on a farm,” says Oliver. Trucks, trains, and ships still run on diesel and aren’t going electric soon. This biodiesel works in standard diesel engines without modifications.

U.S. biofuels hit a sweet milestone: 24 billion gallons yearly capacity as 2024 kicked off – that’s a 7% jump from last year. A 44% surge in renewable diesel and its alternatives: sustainable aviation fuel (SAF), renewable heating oil, and green naphtha/gasoline. This means more drop-in renewables hitting tanks, turbines, and boilers.

More Stories

USDA just pumped $99.6 million into clean fuel infrastructure through HBIIP and REAP programs. The funds come from the Inflation Reduction Act’s climate action budget. Here’s the coolest part: $600 million has already kickstarted 4,500 clean energy projects, while another $180 million is ramping up biofuel availability at 200+ sites nationwide. For energy geeks, this means more E15 and B20 at local pumps – turning America’s farms into renewable fuel powerhouses. Technical barriers like high energy use and complex processing have limited growth.

Published as “Borate Pathway to FAMEs at Near-Ambient Conditions from Used Oil” in Energy & Fuels, the research got funding from an Innovation Catalyst Grant through the Climate Action Solutions Program. The team must still prove the process at an industrial scale. Questions remain about long-term catalyst stability, scaled-up water removal, and integration with existing fuel infrastructure.

The National Biodiesel Board reports the average biodiesel plant in 2022 used temperatures over 140°C and complex separation systems. This 40°C process could slash production energy by 60-70%. Fuel specs matter – biodiesel must meet ASTM D6751 standards for commercial use. The team’s product passes all but water content requirements.

Current commercial biodiesel production averages above 90% conversion efficiency, but demands more energy and creates more waste. This simpler 85% efficient process might prove more practical for distributed, small-scale production. The trade-off between maximum yield and minimum complexity remains an open question for the industry.