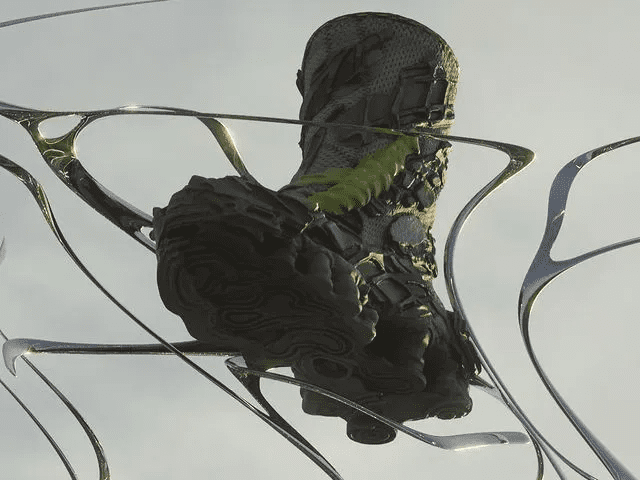

By breaking the mold, MYCL has become the first-ever Mycelium Leather Producer that not only showcases their product but has been worn by actual people on multiple occasions at Paris Fashion Week. Started out as mushroom gourmet producers in 2012, MYCL now focuses on using mushroom mycelium, the vegetative part of mushrooms, for various usages, including creating biomaterial composite boards & Mylea, a novel & strong leather-like material. The materials are easy to develop without expensive, sophisticated processing methods, due to the possibility of mycelium development being controlled & adjusted during their growth span.

As MYCL consistently measures their corporate greenhouse gas emissions, it has been certified as a BCorp & received low carbon awards from MIT Solve. The Solar Impulse Foundation has included Mylea TM in 1,000 efficient solutions. Long term research & penetration are also being developed by MYCL for two other products made from mycelium, including Biobo, a biomaterial board with mycelium as its binding agent, & composite research that explores more possibilities for mushrooms as the key to the future.

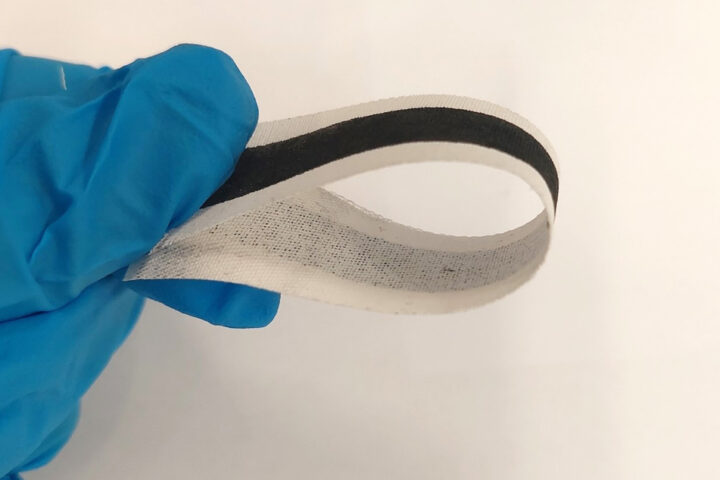

Many new revolutionary doors are opened up for us and humankind by co-creating with Mycelium. The belief of MYCL is in co-creating with nature & fabricating their materials with technology that comes from nature : Myco-Technology. Made from the interlacing network of mycelium, which is inspired by Tempeh, Mylea TM is a strong, sustainable, & eco-friendly material. The structure of the Mycelium leather includes a direct-bonded enforcement of fabric to enhance the tear strength of the material.

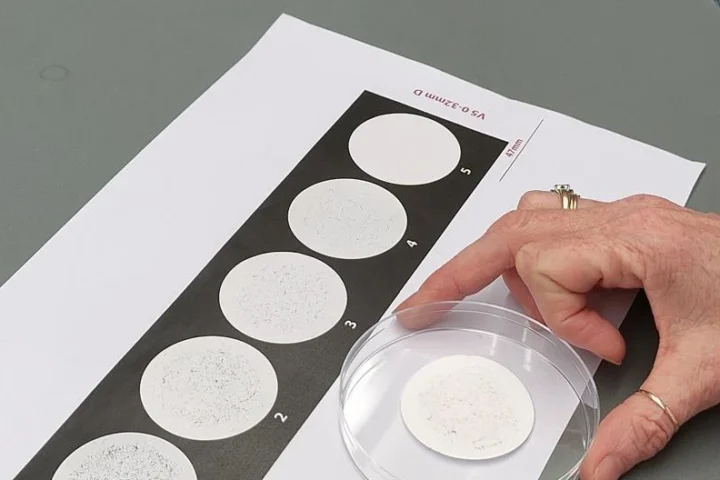

Naturally dyed, the leather comes in a natural brownish color, white for black. The structure of leather itself consists fully of natural layers of mylecium fiber that create a solid & strong bond. Mylea is 70% lower in dichlorobenezene substance (DCB) than in bovine leather based on a 200 kg product comparison using the LCA approach. Based on a 200 kg product comparison using the LCA approach, Mylea is 50% lower in GWP (Global Warming Potential) than bovine leather.

Agroforestry waste upcycled every month amounted to 373 kg. In order to comply with local regulations, the SNI (National Standardization Agency of Indonesia) monitors seven post-production waste parameters constantly. The level of chromium in post-production waste water is kept below 1 ppm as per the regulations of the SNI.

Since 2019, the current college test for Mylea TM has been going on, & so far, we have yet to see its unique & rare colors fade or disintegrate. One of eight Indonesian businesses, MYCL is a certified BCorp that has met high standards of social & environmental performance, accountability, & transparency.

The overall B Impact score of MYCL is 81.5 & excels in terms of environment (36.7) & workers (20.5). A certification of B Corporation by Lab is for businesses that meet high standards of environmental & social impacts, positively impacting all stakeholders: workers, communities, customers, & the environment. A certification of B Corporation TM by Lab TM is for businesses that meet high standards of environmental & social impacts, positively impacting all stakeholders: workers, communities, customers, & the environment.

The fast fashion trends are causing a lot of harm to the environment. The clothes that people stop using or throw away, rarely go into upcycling or recycling. But as fast fashion has gone up, so is the drive for sustainable fashion and clothing. Mycotech is a startup based in Indonesia. They create sustainable products, bio-fabrics and majorly specialize in MyLea, a form of sustainable leather. The MyLea intents to replace leather made from animals, as it is made out of mushroom and soya fragments.

Traditional Leather

Traditional leather that has been in use for centuries is largely made out of animal skins. The most common leathers come from cattle, sheep, goats, equine animals, buffalo, pigs and hogs, and aquatic animals such as seals and alligators.

For leather animals are a forced to dwell in animal farms. The animals are fed and forced into breeding. Leather produced is strong, flexible and durable material obtained from the tanning, or chemical treatment, of animal skins and hides to prevent decay. The leather industry is in close contact with animal husbandry and animal farming.

Similar Posts

Latest

- Sydney Legionnaires’ Outbreak: 1 Dead, 12 Hospitalized

- Global Circularity Falls to 7.2% as Material Use Nears 20th Century Total in Six Years

- Casely Recalls 429,200 Power Pods After 51 Fire and Burn Incidents Raise Lithium Battery Safety Fears

- MTA Boosts Service on 16 NYC Bus Routes Starting June 29, 2025

- Brits Track Finances, Weather and TV More Than Cancer Symptoms, NHS Warns