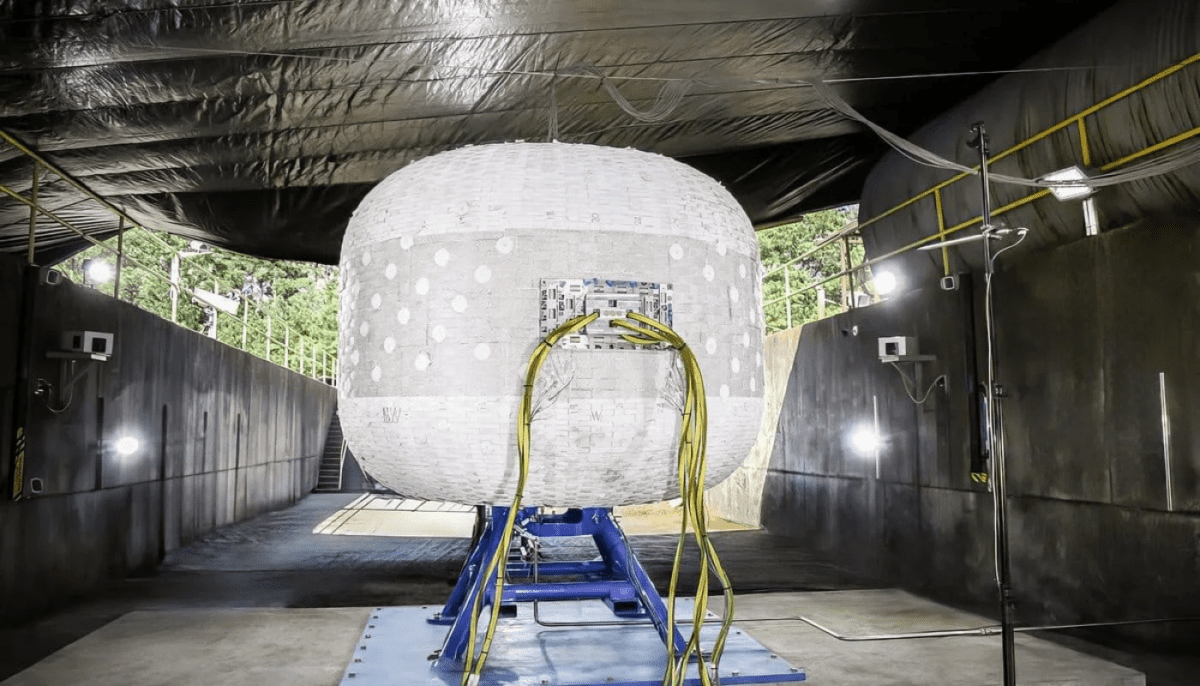

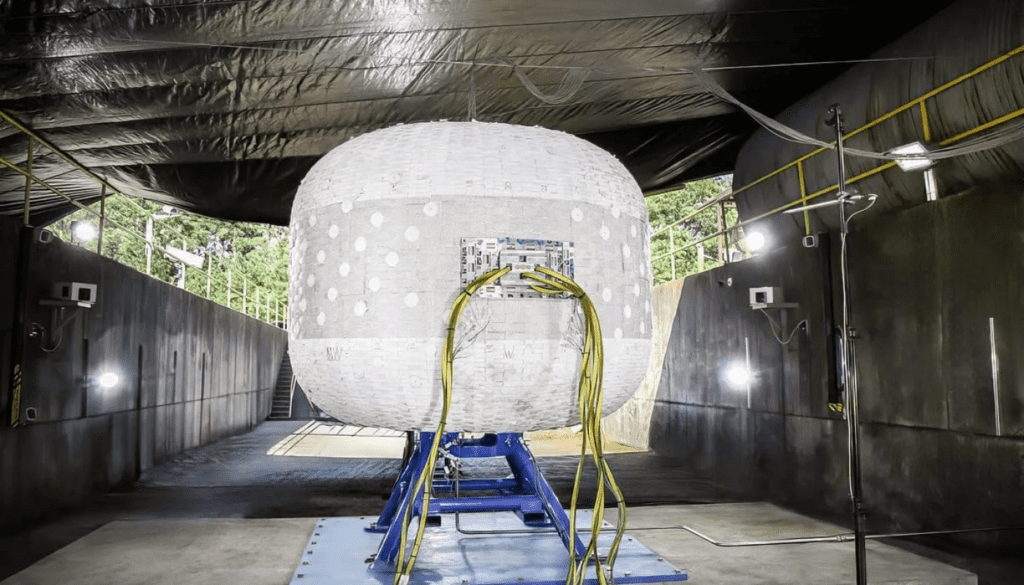

On September 20, 2023, Sierra Space, a pioneer in commercial space technology, announced the successful completion of its fifth structural test for the revolutionary LIFE™ habitat, marking a significant stride in commercial space station development. The LIFE™ habitat, or Large Integrated Flexible Environment, is a groundbreaking project aimed at creating an end-to-end business and technology platform in space, with ILC Dover as the exclusive softgoods technology partner. Sierra Space CEO Tom Vice remarked, “Sierra Space is putting affordable in-space infrastructure within reach so every boardroom can now look to space for their next breakthrough products.”

The company’s innovative approach, combining the LIFE habitat with the highly reusable Dream Chaser spaceplane, aims to significantly reduce the cost of in-space infrastructure and commercialize Low Earth Orbit (LEO). A notable achievement was the inclusion of a metallic window sub-structure, or blanking plate, in the testing, a first in the campaign, propelling Sierra Space towards full-scale testing of LIFE by the end of the year. The blanking plate is a critical component, emulating future design elements such as windows, robotic arms, or antenna attachment points, and its successful integration marks a technological breakthrough.

Shawn Buckley, Sr. Director Engineering and Product Evolution Director for Sierra Space Destinations, emphasized the game-changing nature of infusing metallics into softgoods pressure shell technology. The recent Ultimate Burst Pressure (UBP) test surpassed previous maximum burst pressures, providing a 33% margin over the certification standard for full-scale LIFE testing and a nearly 20% improvement over the previous design. Sierra Space stands out as the only active commercial space company to conduct both UBP and Creep tests on an inflatable softgoods architecture at sub or full scale with a blanking plate.

Similar Posts

The LIFE habitat, once fully developed, will feature a minimum of two windows, a crucial element for crew members to combat feelings of confinement and to witness the beauty of Earth. Robert Reed, President of Space and Engineered Solutions at ILC Dover, expressed commitment to advancing human spaceflight and sustaining life in LEO, stating, “We are proud to have contributed to this crucial endeavor and further showcase the reliability of our inflatable habitat.” The UBP test was supported by NASA through a Reimbursable Space Act Agreement, with services provided by Marshall Space Flight Center to aid Sierra Space in its technology development and risk reduction activities.

The testing took place in Huntsville, Alabama, on Redstone Arsenal in the flame trench of the historic Saturn 1/1B test stand, adding a historical touch to the innovative endeavor. The LIFE habitat is a three-story commercial habitation, science, and bio pharma platform designed for human living and working in LEO and beyond, constructed of high-strength, “softgoods” materials. Sierra Space’s advancements are driving significant cost savings for operating on-orbit, making space more accessible and affordable for a variety of applications.

With over 30 years and 500 missions of space flight heritage, Sierra Space is at the forefront of innovation and commercialization of space in the Orbital Age™. The company is enabling the future of space transportation with Dream Chaser®, the world’s only commercial spaceplane. Sierra Space is also bringing LIFE™ to Low Earth Orbit with its modular commercial habitation and science platform for future commercial space stations.

ILC Dover is a world-leader in the design and production of space exploration technology, including spacesuits, space habitats, and inflatable landing systems. ILC Dover’s spacesuits have been worn during more than 250 space flights, six Moon landings, and over 3,000 hours of spacewalks without a single failure. The company has developed two commercial suits, Sol™, a Launch, Entry, and Abort (LEA) suit, and Astro™, an Extravehicular Activity (EVA) and Planetary Exploration suit.

Sierra Space and ILC Dover are working together to create high-quality, advanced technology for space exploration. Their successful tests of the LIFE habitat are opening up new opportunities for human space travel and exploration. By combining metal components with flexible materials, they’ve made a big technological advance, allowing for more design possibilities in space habitats. Sierra Space’s partnership with NASA and use of historic testing sites show a mix of innovation and tradition in their work. Their progress is helping to increase commercial activity in Low Earth Orbit and extend human presence in space. The work on the LIFE habitat is a step towards using space not just for exploration, but also for innovation and development.

Lockheed Martin has conducted successful burst tests on a sub-scale inflatable space module, a technology similar to the Orbital Reef’s approach, aiming to develop lightweight and expandable habitats for lunar and Martian habitation. Both Lockheed Martin’s inflatable habitat concept and the Orbital Reef project emphasize cost-effectiveness, efficiency, and adaptability, offering innovative solutions for constructing substantial structures in space and enabling sustainable human presence beyond Earth. The tests by Lockheed Martin and the developments by Orbital Reef represent parallel strides in aerospace technology, focusing on the integration of critical components such as windows, hatches, and life-support materials, and contributing to the vision of creating habitable environments in space.