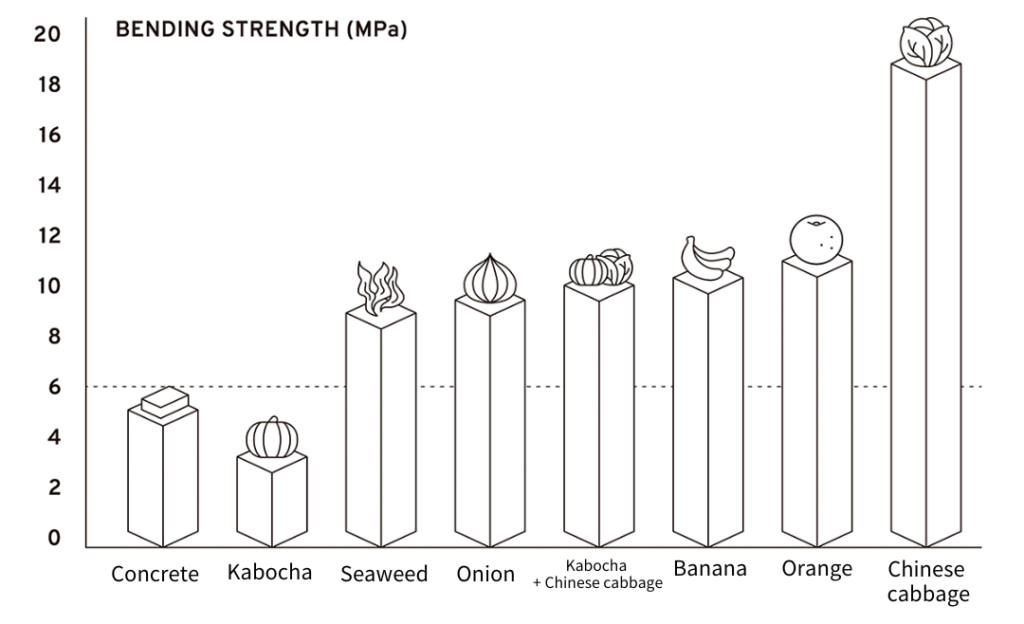

Japanese researchers have achieved 18 MPa flexural strength from Chinese cabbage waste—creating construction-grade materials four times stronger than concrete. The achievement emerged from the University of Tokyo’s Institute of Industrial Science, where Associate Professor Yuya Sakai’s concrete recycling research led to discoveries in biomaterial strength.

The researchers developed precise processing parameters which involved initial drying, followed by pulverization using a regular blender, and final hot pressing with water and seasonings. This three-phase approach eliminates the need for plastic additives, a limitation that affected previous food waste cement research.

The material science centers on the interaction between sugar content and dietary fiber. Chinese cabbage contains what Sakai’s team found to be a perfect balance—when heated, the glucose softens, flows into gaps, and adheres. However, sugar content alone doesn’t determine strength. The mutual interactions between sugar and dietary fiber yield stronger materials than those containing only one component.

Material durability testing conducted over four months showed no degradation from insects, worms, or fungi, with appearance remaining stable. Surface treatment with urethane or natural lacquer provides water resistance while maintaining the material’s biodegradable properties, though removing its edible characteristics.

Kota Machida of Fabula Inc., established in October 2021 to commercialize the technology, explains: “We also found that Chinese cabbage leaves, which produced a material over three times stronger than concrete, could be mixed with the weaker pumpkin-based material to provide effective reinforcement.” Their testing validated thirty distinct food waste materials, with products now including plates, coasters, and furniture components.

The environmental impact data proves compelling: conventional cement production generates 8% of global carbon dioxide emissions. Japan’s annual food waste reaches 5.7 million tons, with government targets aiming to reduce this to 2.7 million tons by 2030.

Similar Posts

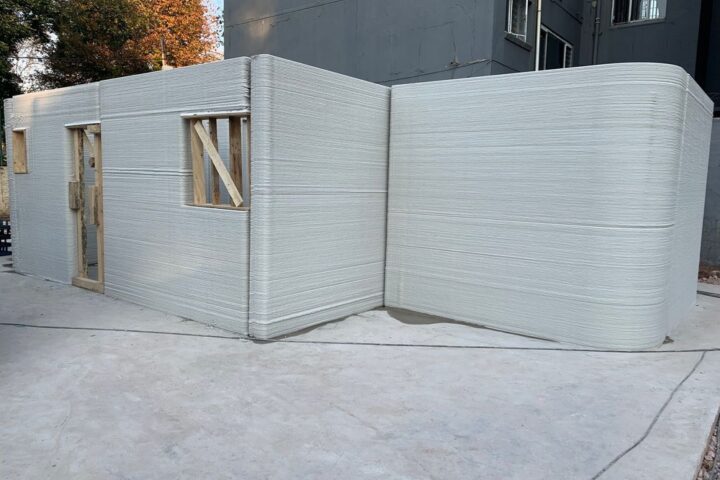

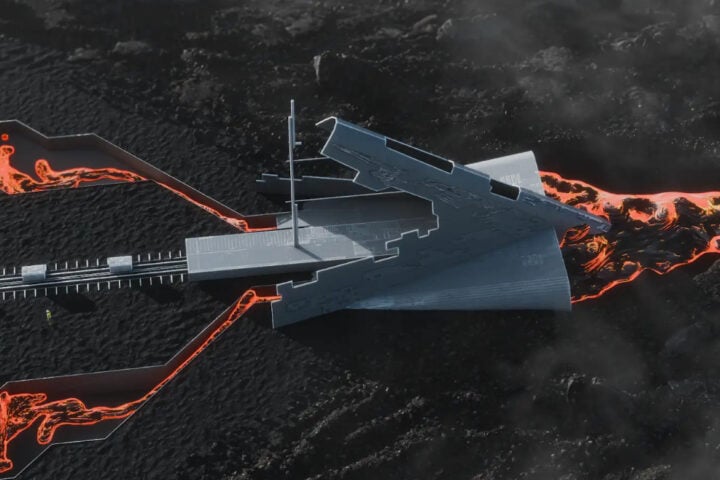

Applications extend into disaster response. A mobile setup combining a pulverizer and pressing machine enables on-site conversion of disaster debris into building materials. The team has also developed technology for desert sand, using ethanol and an alkali metal catalyst at 110°C to create concrete-strength blocks overnight. Current research explores lunar regolith processing for extraterrestrial construction.

The technology builds on Sakai’s research in concrete recycling, where investigating moisture-induced dimensional changes led to discoveries about powder compaction strength. This understanding transferred to organic materials, revealing optimal processing parameters through systematic experimentation.

The World Food Programme estimates global annual food waste at $1 trillion. The pending patent application through the University of Tokyo’s Institute of Industrial Science covers both the basic technology and specific applications. As development continues through Fabula Inc., applications range from current products like coasters and plates to potential future construction materials that address both waste management and building industry needs.