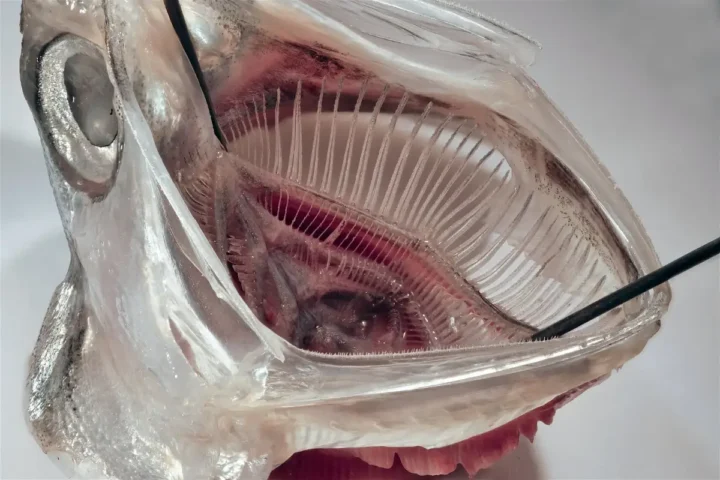

A study led by the University of California has proven that a bacteria with a plastic-based diet help reduce plastic pollution by embedding these microbes into thermoplastic polyurethane (TPU). This later helps to degrade it quickly after coming into contact with soil and moisture. TPU is common in products such as footwear, mobile phone cases, or car parts. Currently, there is no recycling flow for polyurethanes, and most end up as waste in landfills or seep into the environment at the end of their useful life.

The study co-senior author Jon Pokorski, a nanoengineering professor at the UC San Diego Jacobs School of Engineering and co-lead of the university’s Materials Research Science and Engineering Center (MRSEC), said, “It’s an inherent property of these bacteria.” He says ahead, “We took a few strains and evaluated their ability to use TPUs as a sole carbon source, then picked the one that grew the best.”

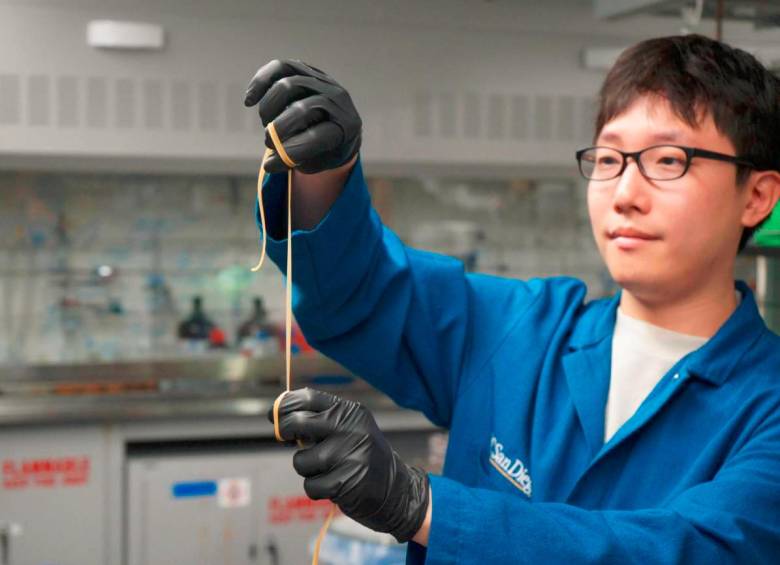

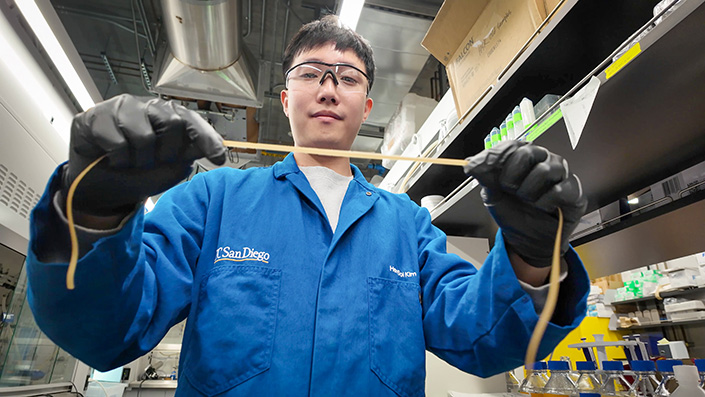

Han Sol Kim, a scientist at the University of California in San Diego (USA) and co-author of the study published in the journal Nature Communications, elaborates that the spores they have used were specifically selected and designed for TPU. The extrusion technique to melt and mold it is versatile and can be used to process many other polymers. This means that if we can manufacture spores that work for other plastics, our method can be applied to more materials,” says Han Sol Kim, a scientist at the University of California in San Diego (USA) and co-author of the study published in the journal Nature Communications.

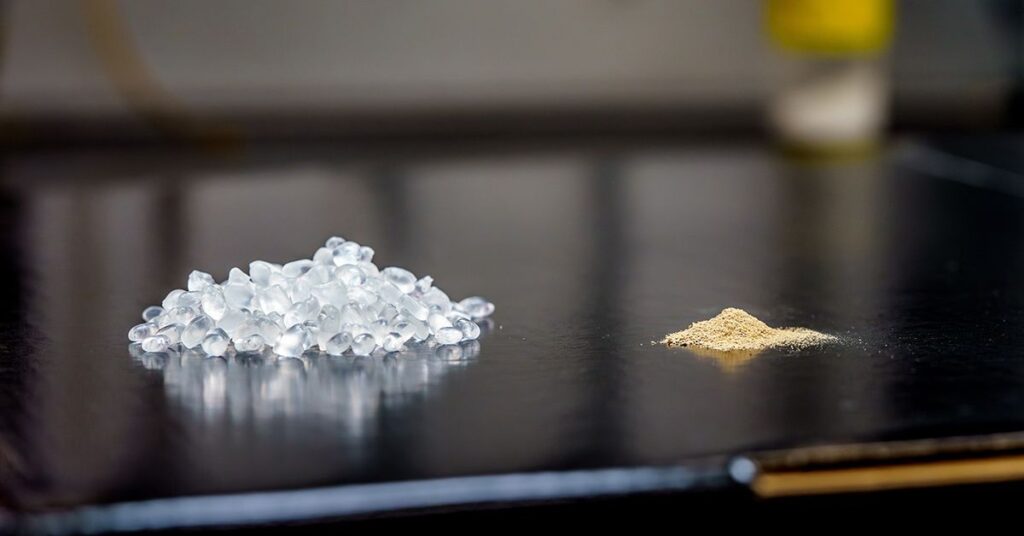

The scientist explains ahead how the extrusion technique to include the spores in the plastics consists of melting polymers in a liquid state by applying heat and shear [opposite parallel forces] to facilitate the mixing of various additives that improve their properties. We added spores as a ‘biofunctional additive’ to the melted TPU.

Unlike fungal spores, which serve a reproductive function, bacterial spores have a protective protein shield that allows the bacteria to survive in a vegetative state. As per Han Sol, the bacteria can remain dormant for many years until they are exposed to favourable environments that allow them to thrive. Soil moisture and nutrients are good triggers for spore germination. So it is likely that these remain inactive until they detect these soil characteristics, which are scarce during the plastic’s useful life, according to Han Sol Kim.

Similar Posts

To evaluate the biodegradability of the material, they placed the strips in environments with both active and sterile microbes. The compost facilities were maintained at 37 degrees Celsius with a relative humidity ranging between 44 and 55%. Water and other nutrients from the compost triggered the germination of the spores within the plastic strips, which reached 90% degradation in five months.

“Our study shows that more than 90% of mass was lost within five months, which is twice as fast as the degradation of plastic without spores. And more than 70% of plastic was biomineralised into CO2 within six months.”

– Han Sol Kim, Scientist at the University of California in San Diego (USA) and Co-Author of the Study Published in the journal Nature Communications,

The experts suggest that biodegradable plastics usually weaken the mechanical properties of polymers, limiting their applications and lifespan. However, the TPU used in this research is a special elastomer with exceptional strength. By adding spores as a bioadditive, we further enhance its firmness while facilitating its degradation, the researchers assure.