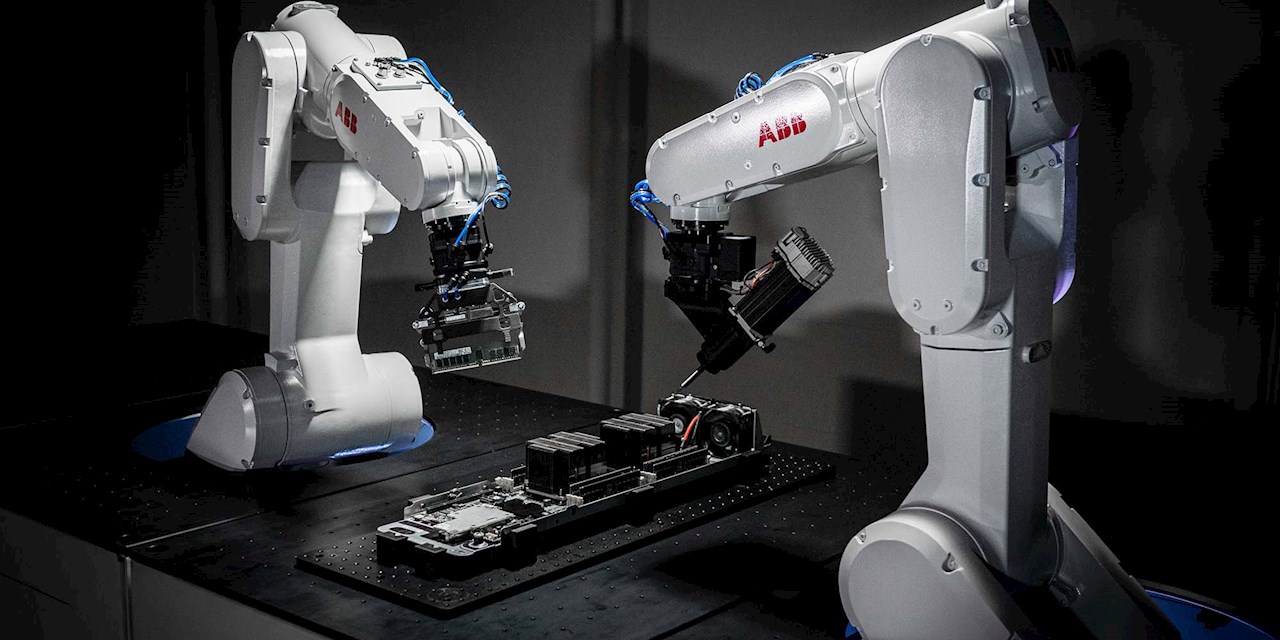

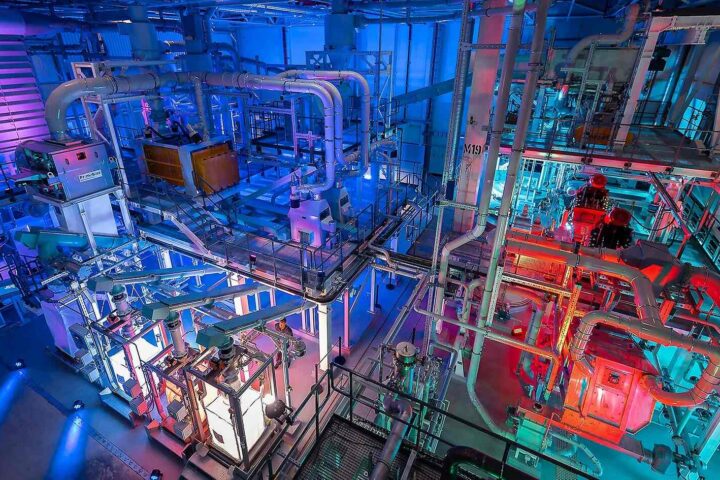

In a world grappling with escalating electronic waste, ABB Robotics and US startup Molg have joined forces to develop automated microfactories for recycling data center equipment. This partnership emerges as global e-waste projections reach an alarming 75 million tons by 2030, with data centers contributing 2.6 million tonnes annually.

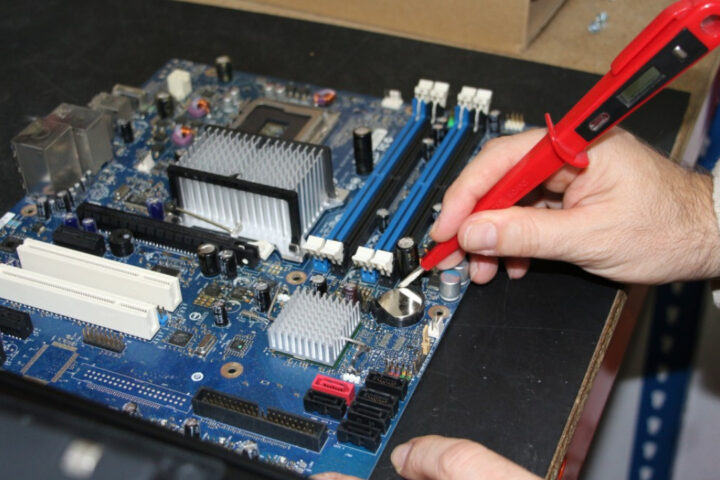

The robotic microfactories will autonomously disassemble complex electronic equipment, including servers, laptop PCs, and industrial electronics. This automated approach offers an alternative to manual disassembly or disposal in landfills and incinerators.

“Through this collaboration, we continue to realize our vision of helping organizations operate more efficiently and sustainably,” says Craig McDonnell, Managing Director Business Line Industries at ABB Robotics. “With Molg, we are creating new applications for industrial robotics in a growing segment with circularity and sustainability at the core.”

The rapid advancement of AI, machine learning, and cloud computing has increased the frequency of data center upgrades. The automated disassembly process serves multiple purposes:

- Recovery of rare earth elements (REEs) for reuse in new electronic equipment.

- Reduction of toxic exposure risks to workers.

- Compliance with increasing regulations on decommissioned equipment handling.

Rob Lawson-Shanks, CEO & Co-Founder of Molg, states: “With this investment from ABB, we can accelerate our work to create more sustainable, circular manufacturing processes for electronics that ensure valuable materials are kept in circulation and enhance supply chain resilience.”

More Stories

The collaboration has attracted substantial backing. ABB Robotics & Automation Ventures participated in Molg’s seed funding round, led by Closed Loop Partners’ Ventures Group. Additional investors include:

- Amazon’s Climate Pledge Fund

- Overture

- Elemental Impact

- Techstars Ventures

Molg’s innovation earned recognition as a winner in ABB’s Motion drive business’s Accelerating Circularity Startup Challenge 2023.

The microfactory solution targets hyperscalers operating large data center networks and IT Asset Disposition (ITAD) companies. Beyond the immediate recycling capabilities, Molg’s portfolio includes design-for-circularity and component traceability software tools. These enable manufacturers to create products designed for eventual disassembly and recycling.

The initiative addresses several documented e-waste management issues:

- Safe disposal of toxic elements that can damage the environment and human health.

- Recovery and reuse of valuable materials including rare earth elements.

- Automated handling of complex electronic product disassembly.

- Regulatory compliance for decommissioned equipment.

The partnership represents a concrete step toward addressing e-waste management in the data center sector.