Every year, we throw away about 350 million metric tons of plastic waste. But some companies are turning this household waste into something useful: building materials for homes and offices.

Photo Source: The Good Plastic Company (Facebook)

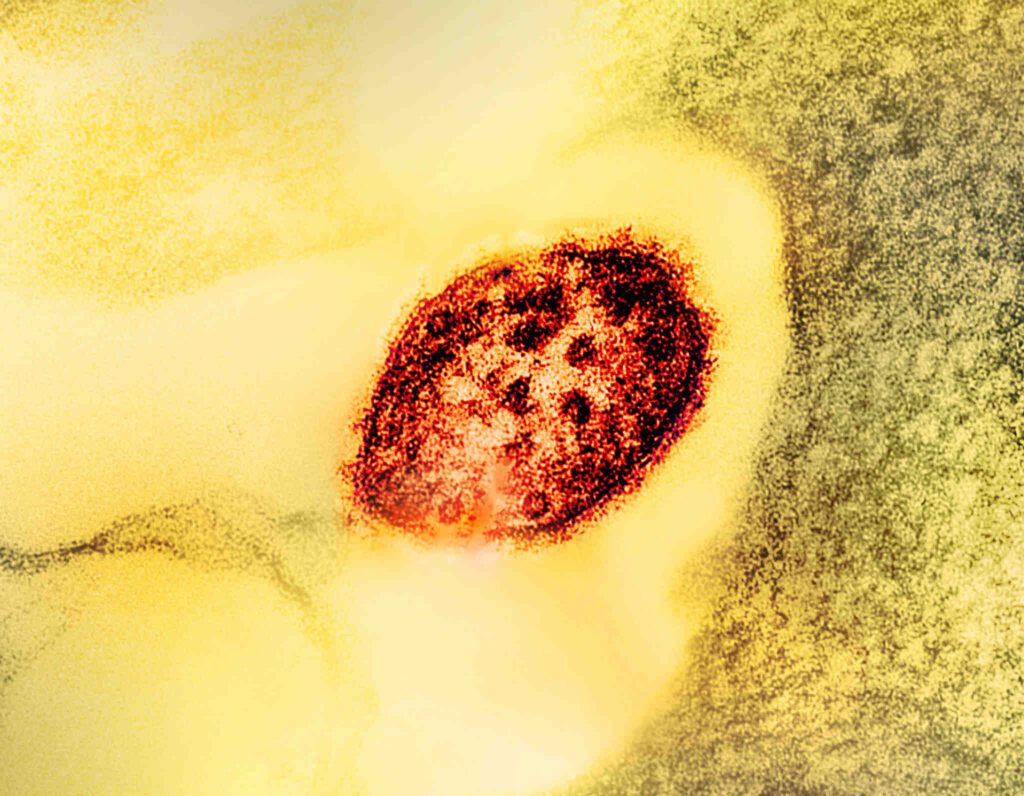

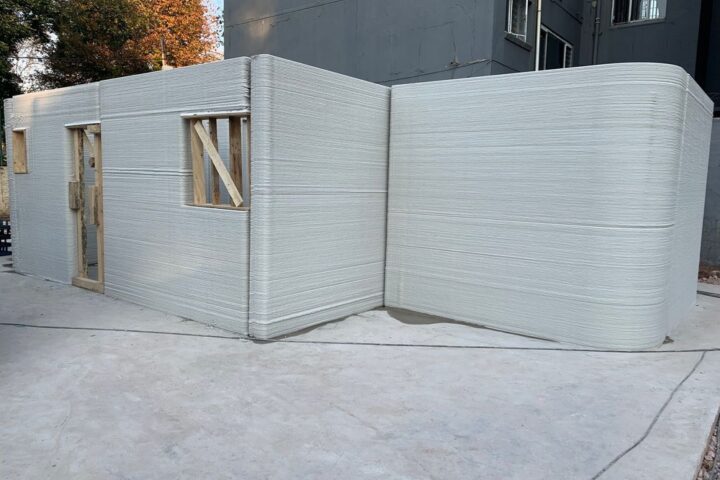

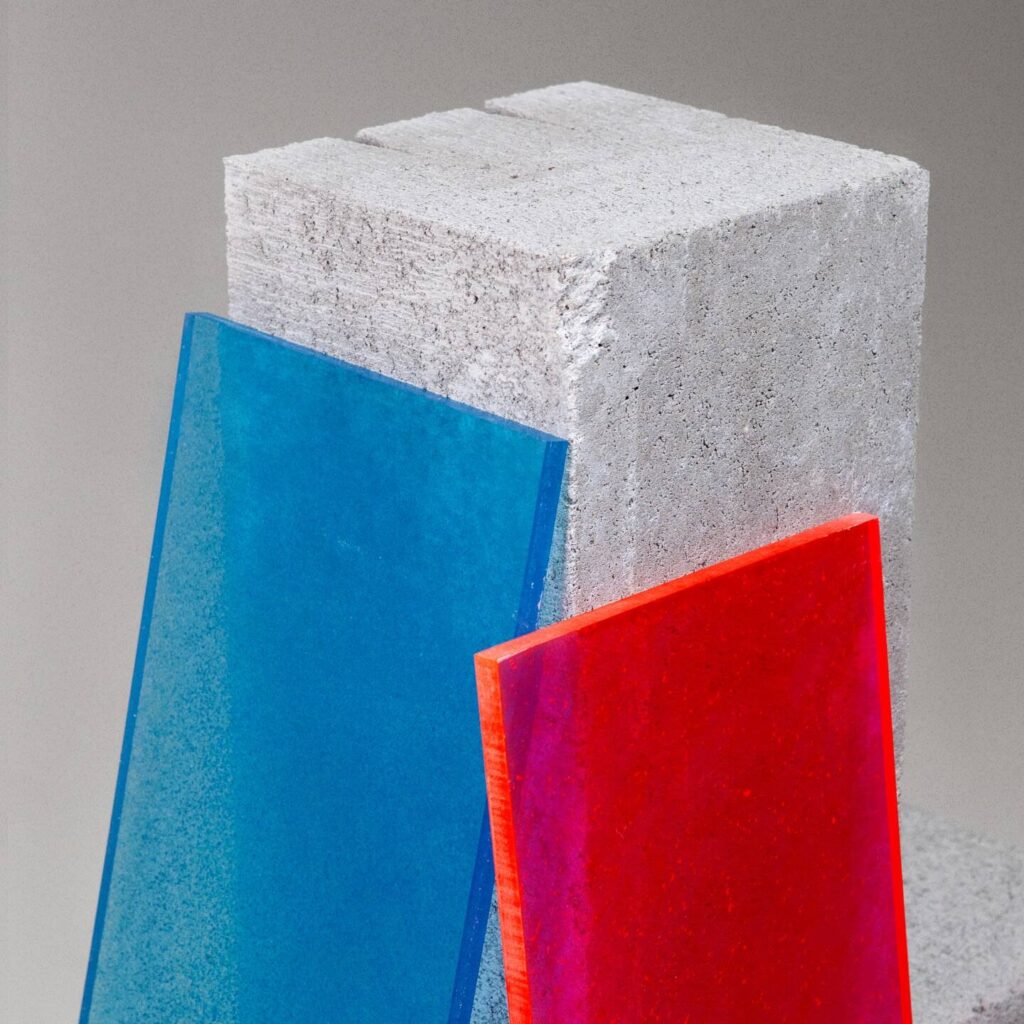

Dr. William Chizhovsky said that they had started by experimenting with everyday items like shampoo bottles, old toys, and even plastic waste from beaches. He added that his team now transforms these materials into Polygood panels, which can be used for kitchen countertops, wall coverings, and even building facades.

Photo Source: The Good Plastic Company (Facebook)

These panels aren’t just recycled – they’re designed to reduce microplastic pollution. Unlike traditional plastic processing that creates microplastics during manufacturing, the company’s special heating process prevents these tiny particles from forming. This means less dust generation both in factories and when the panels are installed.

Photo Source: The Good Plastic Company (Facebook)

The panels are made from two main sources: 70% comes from household items like old refrigerators and plastic cutlery, while 30% comes from factory leftovers. “We verify our suppliers to ensure their quality and values match our vision and stringent procedures,” Chizhovsky explains. All suppliers hold EuCertPlast certification, guaranteeing traceability and quality of the recycled plastics.

Similar Posts

The panels meet ISO standards and have earned Cradle to Cradle Bronze certification. They’re made using thermopressing technology, which operates at lower temperatures than conventional molding, minimizing material degradation. When homeowners eventually want to replace them, the company offers a free take-back program – they’ll collect old panels and offcuts for recycling.

Photo Source: The Good Plastic Company (Facebook)

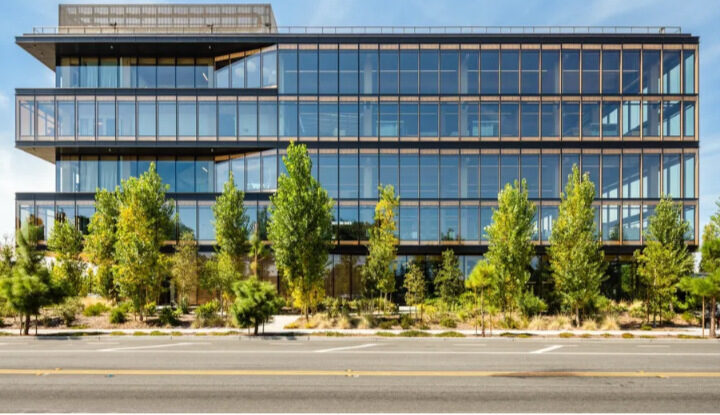

Nike has made custom panels using recycled shoes. The Good Plastic Company will open a facility in the U.S. in the near future.

Photo Source: The Good Plastic Company (Facebook)

Building with recycled materials helps cut down the 350 million metric tons of plastic waste we create each year. Instead of plastic ending up in oceans, it can become useful building materials. This gives people a way to choose recycled materials for their building projects.

Photo Source: The Good Plastic Company (Facebook)

This new way of using plastic waste shows a different approach to handling waste. While one company alone can’t fix the plastic waste problem, it shows how we can turn used plastic into new building materials.