Arctic Circle Laboratory: Where EVs Learn to Handle Ice

North of the Arctic Circle in Jokkmokk, Sweden, Polestar conducts rigorous winter testing on frozen lakes. This extreme environment serves as the ultimate proving ground for electric vehicle performance in sub-zero temperatures. Custom-built circuits on the ice feature varied track designs—tight corners, long sweeping turns, and high-speed loops—to evaluate traction, handling, and stability under challenging conditions.

The ice thickness measurements are precise: while Swedish standards allow as little as 25 cm for certain vehicles, Polestar’s testing areas often exceed one meter to ensure safety. Weather conditions fluctuate from sub-zero temperatures to occasional midday thawing, adding complexity to the testing process and reflecting real-world winter driving scenarios.

Cold Weather EV Performance: Battery Chemistry Makes a Difference

Temperature plays a critical role in EV battery performance. Cold weather reduces chemical reaction rates in lithium-ion batteries, affecting efficiency, charging capability, and range. Polestar uses NMC ( Nickel Manganese Cobalt) battery cells, which perform better in cold weather compared to LFP (Lithium Iron Phosphate) alternatives.

NMC batteries maintain higher energy density and better cold-weather performance, though they come at a higher cost. According to battery technology research, LFP batteries experience greater capacity and power output reduction at low temperatures due to decreased ionic conductivity and slower electrochemical reactions.

This technical edge was demonstrated during the independent El Prix 2025 winter range test in Norway, where the Polestar 3 Long Range Dual Motor with Performance Pack achieved remarkable results. The vehicle traveled 531 km—just 5% short of its official 561 km WLTP rating. For context, the next closest competitor fell 9% short of its rating, while another car managed similar overall distance but was 24% below its WLTP figure.

Thermal Management and Pre-conditioning: Essential Cold-Weather Strategies

Pre-conditioning—warming the battery and cabin while still connected to a charger—is essential for maintaining performance. This process reduces in-drive energy consumption and mitigates range loss. Polestar’s thermal management system ensures optimal operating temperature for battery cells while balancing energy efficiency.

Heat pump technology also plays a crucial role. Unlike resistive heating, heat pumps transfer rather than generate heat, significantly improving energy efficiency. Even with decreased efficiency in extremely cold temperatures, heat pumps remain more efficient than conventional resistive heating systems.

Regenerative Braking in Cold Weather: The Balance Challenge

Cold temperatures increase internal battery resistance, reducing the ability to efficiently capture regenerative energy. Polestar implements sophisticated software algorithms to balance regenerative and friction braking, ensuring stability and safety.

When temperatures drop severely, the system might limit regenerative braking to prevent overcharging or stability issues, relying more on traditional friction brakes. This adaptive approach maintains consistent vehicle control regardless of temperature fluctuations.

The Polestar Arctic Circle Collection: Rally-Inspired Performance

Polestar has created a unique “Arctic Circle” collection featuring specially modified versions of their entire lineup: Polestar 2, 3, and 4. These rally-inspired vehicles express the brand’s performance DNA with significant technical upgrades:

- Increased ride height (+30mm for Polestar 2, +40mm for Polestar 3, +20mm for Polestar 4)

- Custom Öhlins 3-way adjustable dampers with external gas reservoirs

- Specialized Pirelli Scorpion All Terrain Plus tires with 4mm studs (250 studs for Polestar 2, 300 for Polestar 3 and 4)

- OZ Racing Rally wheels (19″ for Polestar 2, 20″ Rally Legend wheels for Polestar 3 and 4)

- Recaro Pole Position bucket seats

- Stedi Quad Pro LED front spotlights and additional lighting

- Rally-inspired mud flaps and Swedish gold tow hooks

Each vehicle maintains its distinct characteristics: the Polestar 2 resembles a rally car, the Polestar 3 projects a bold SUV stance, and the Polestar 4 presents itself as a fast, athletic machine. The collection debuted at the 2025 FAT Ice Race in Zell am See, Austria, on February 1st.

Similar Posts:

Vehicle Dynamics on Ice: Torque Vectoring and Weight Distribution

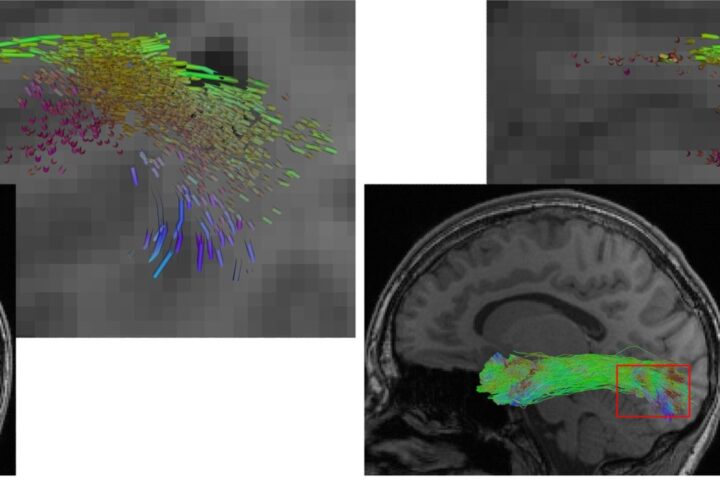

Advanced systems like torque vectoring distribute power to individual wheels, enhancing traction and stability on slippery surfaces. This technology allows precise control of wheel slip, improving cornering performance and reducing understeer or oversteer.

Vehicle weight distribution affects handling significantly. While EVs typically have a lower center of gravity due to their battery pack positioning, their overall weight impacts inertia and handling. This requires careful tuning of suspension and stability control systems.

Joakim Rydholm, Polestar’s Head of Driving Dynamics and a rally driver with over 30 years of motorsport experience, explains: “It’s a dream for an engineer. We have raised the suspension, used Öhlins racing dampers, but we have tweaked it in the SUV direction for Polestar 3 and crossover direction for Polestar 4… Because if you have control in a car, you are fast. That’s what we have achieved here.”

Software-Defined Vehicle: Continuous Improvement Through OTA Updates

As Europe’s first software-defined vehicle, the Polestar 3 receives regular over-the-air (OTA) updates to enhance functionality and performance. Since its launch in June 2024, Polestar has implemented nine software updates to the flagship SUV.

The latest update adds features like walk-away locking and digital key functionality for selected devices. This allows compatible smartphone users to unlock, lock, or start their vehicle without removing their phone from their pocket.

For model year 2026 the Polestar 3 will be delivered with an upgrade from its current -generation NVIDIA DRIVE AGX Xavier processor to a new, more powerful, NVIDIA DRIVE AGX Orin processor.

Tire Technology: Studded Performance

Tire selection is critical for winter performance. The Arctic Circle collection uses specialized Pirelli Scorpion All Terrain Plus tires with 4mm studs—250 studs for the Polestar 2 and 300 for the Polestar 3 and 4. These provide exceptional grip on ice and snow, crucial for maintaining traction and control.

For road driving, the vehicles are equipped with Pirelli winter tires: P Zero Winter for Polestar 2 and Scorpion Winter 2 for Polestar 3 and 4. Tire pressure and compound influence also influence winter performance, affecting grip, rolling resistance, and handling characteristics.

Climate Change Context: Shifting Testing Conditions

The winter testing environment itself reflects climate change impacts, with more variable weather conditions including milder temperatures and occasional thawing. These changes add complexity to the testing process and highlight the need for EVs to perform consistently across fluctuating conditions.

Michael Lohscheller, Polestar CEO, notes: “We develop our cars above the Arctic Circle in Sweden, so it’s no surprise for us that Polestar 3 performs better than the competition in challenging conditions.”

Range Options: Expanding Customer Choice

The Polestar 3 lineup offers multiple powertrain configurations to suit different customer needs. The Long Range Dual Motor with Performance Pack delivers up to 380 kW (approximately 509 hp) and an updated WLTP range of 567 km for model year 2025 vehicles.

For customers prioritizing maximum range, the recently introduced Long Range Single Motor variant provides an impressive 706 km WLTP range from its 111 kWh battery. This rear-wheel drive configuration balances performance with extended travel capability.

What Next for EV Winter Performance

As climate patterns continue to evolve, EV manufacturers must adapt their testing protocols and vehicle designs. Continuous software improvements through OTA updates allow manufacturers to optimize cold-weather performance and battery management even after vehicles reach customers.

Polestar’s comprehensive winter testing program demonstrates their commitment to developing resilient, high-performance EVs capable of handling extreme conditions. The minimal range loss, exceptional handling, and effective battery management in sub-zero temperatures establish a benchmark for the industry as electric vehicles continue to gain market share worldwide.

Polestar Winter Testing FAQs