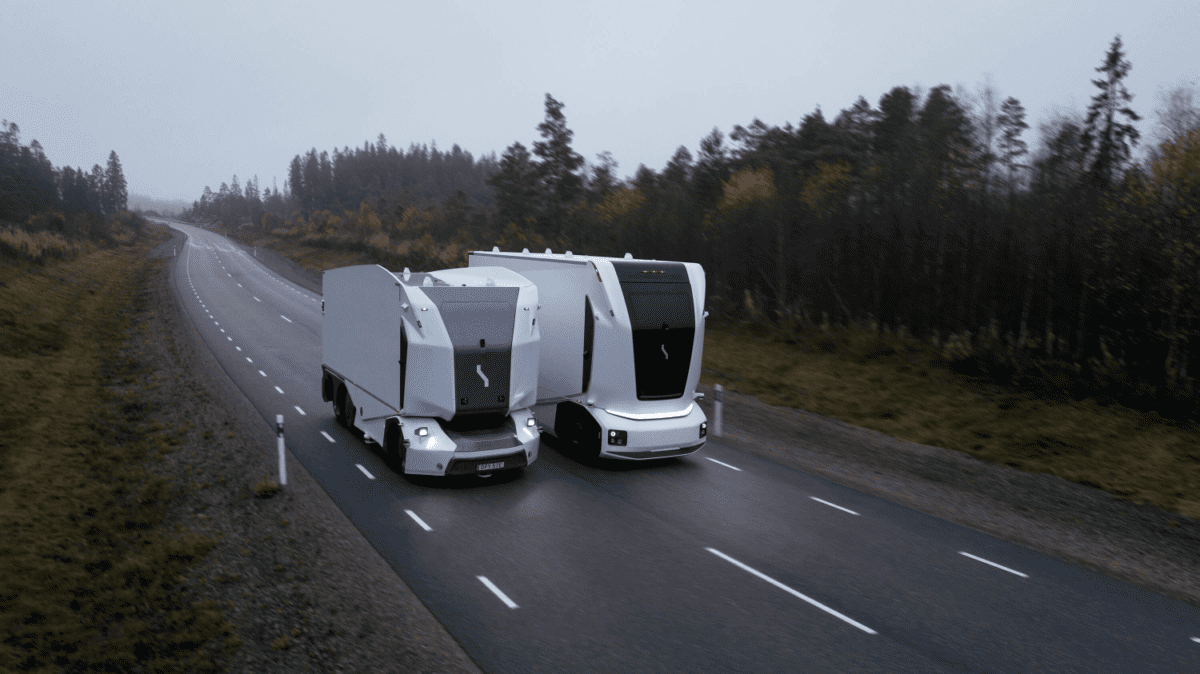

The Gen 2 is a unique truck that doesn’t have a traditional cabin where a driver would sit. Autonomous operability is being developed for transport without physical human presence. Instead of a driver, the Gen 2 is controlled remotely by an operator who supervises multiple vehicles at the same time.

Einride, a transportation company based in Sweden, is responsible for manufacturing both the Gen 2 truck and the remote operation station. However, their goal goes beyond just creating autonomous electric vehicles (EVs). They want to revolutionize the way goods are transported worldwide. By combining battery-electric power, automation, and data analysis, Einride is paving the way for the future of freight transportation.

The futuristic appearance of Einride’s equipment caught the attention of tourists in New York City when they parked an electric truck and a cab-less Autonomous Electric Transport vehicle on a busy street. Passersby couldn’t resist taking pictures with these innovative freight movers.

While some companies are taking cautious steps towards the future of transportation, Einride’s leaders express confidence in their ability to drive the freight industry forward. The Gen 2 truck, alongside the Einride Remote Interface, allows an operator to effectively supervise multiple vehicles simultaneously.

Einride adopts a comprehensive approach to freight transportation by thinking in terms of grids or transportation networks. Their grid system encompasses everything required to keep freight moving smoothly, including vehicles, trailers, drivers, software, and charging stations. To plan, optimize, and monitor this grid system, Einride has developed the Einride Saga platform, which utilizes artificial intelligence to analyze all aspects of freight transportation and facilitate the transition to electric power.

Similar Post

The Einride grid simplifies long-distance freight logistics, eliminates inefficiencies in the industry, and introduces smart freight transfers to prevent delays caused by factors such as battery recharging or driver changes. It handles all logistical touchpoints, including software, charging infrastructure, and maintenance.

In the United States, Einride is collaborating with GE Appliances to transport goods using their electric tractors and cab-less transport vehicles. GE Appliances has found the data provided by Einride invaluable for achieving their sustainability goals. They utilize the CO2 calculators in Einride Saga to monitor emissions and optimize routes, leading to better benefits from electric trucks and reduced carbon emissions.

Another notable customer of Einride is Oatly Group AB, a non-dairy oat milk manufacturer aiming to achieve 100% sustainability in their ground transportation operations by 2029. Oatly has acquired five Einride electric trucks and employs Einride’s Saga services, which include setting up charging infrastructure and connectivity services. Einride manages Oatly’s electrified fleet, which operates in Utah and New Jersey. By understanding Oatly’s freight footprint and applying operational algorithms, Einride assists in planning infrastructure and timing the electrification journey.

The impact of Einride’s solutions is significant. Oatly’s five Einride-connected trucks are estimated to reduce 880,000 pounds of CO2 in their first year of operation compared to diesel trucks on the same routes, resulting in an impressive 87% reduction in carbon emissions.