Advanced materials research in the International Space Station (ISS) of NASA is revealing new possibilities for stronger, more efficient products. These experiments, conducted in microgravity conditions, are tackling real-world challenges in manufacturing and construction.

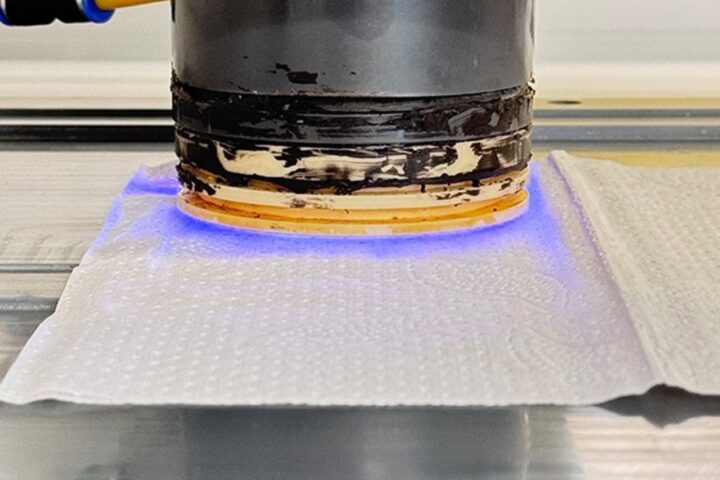

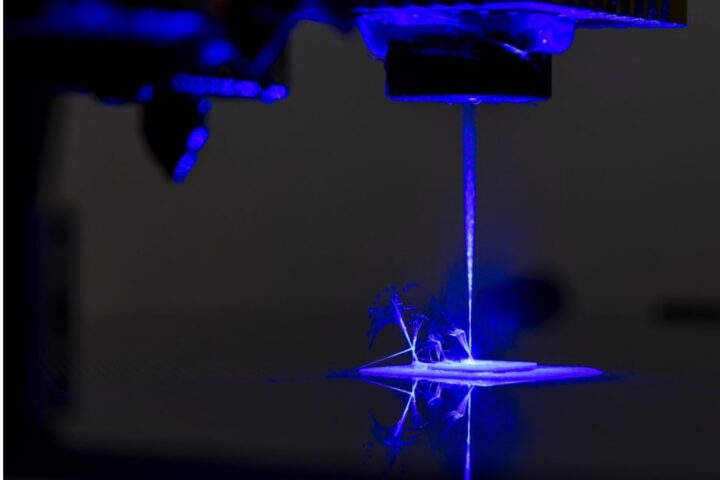

The BRAINS experiment (Brazing of Aluminum alloys IN Space) studies metal bonding at precisely 450 degrees Celsius – hot enough to melt metal but not so hot that it destroys the materials being joined. When metals bond in space’s zero gravity, they form different patterns than on Earth. A construction worker using brazing techniques on a bridge support could soon benefit from this research, as it shows how to create stronger, more reliable joints.

“Creating materials that can withstand intense environments while reducing weight is crucial,” explains Amy Hiltabidel, Technology Licensing Manager at NASA Glenn. Her team’s work focuses on Silicon Carbide Fiber-Reinforced Ceramic Matrix Composites, materials that could make aircraft engines both lighter and more durable.

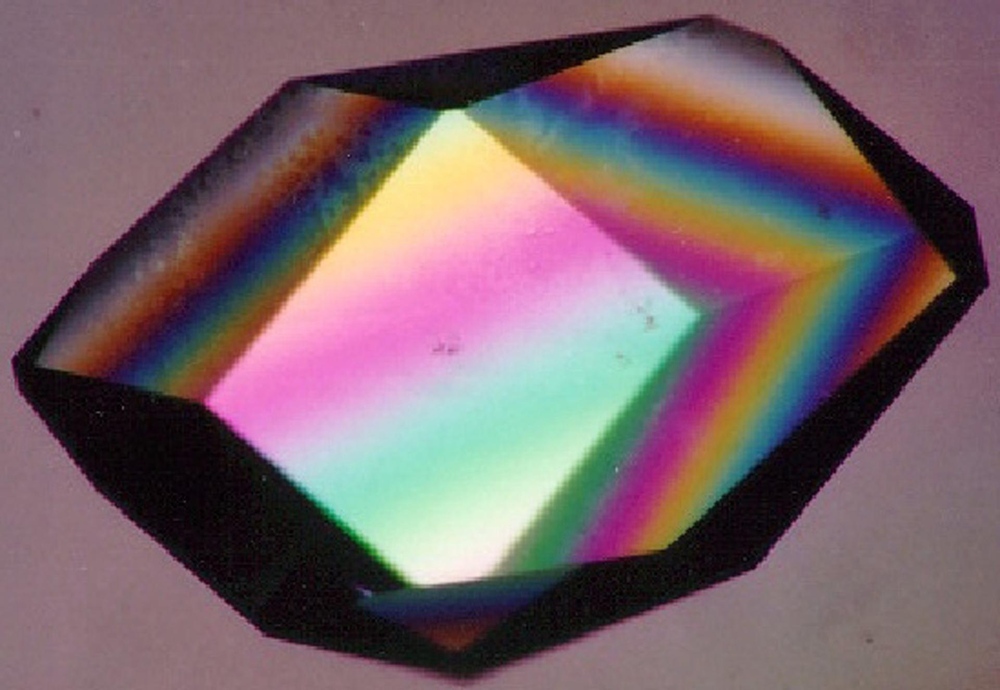

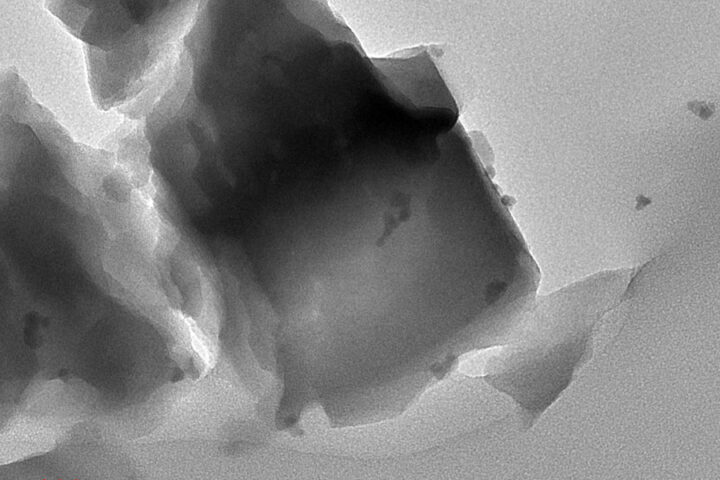

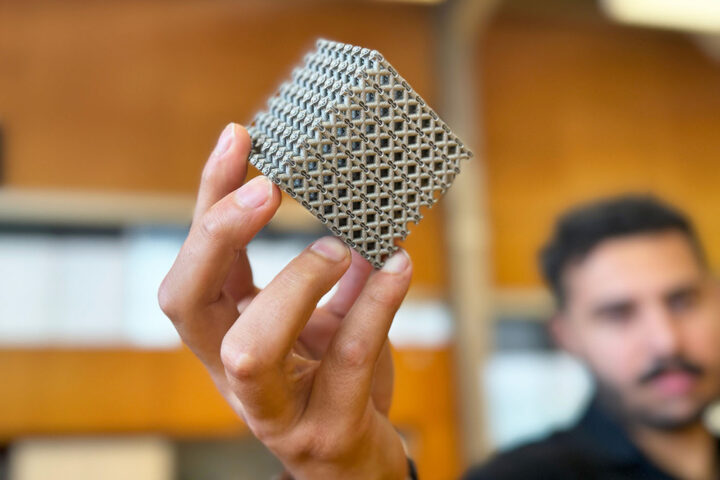

In the station’s metal alloy experiments, researchers watch how liquid metal crystals form without Earth’s gravity pulling them into familiar patterns. These crystals, called dendrites, look like tiny metal snowflakes under a microscope. The size and shape of these dendrites determine how strong the final metal will be. A car frame made with these improved metals could be both lighter and more crash-resistant.

Similar Posts

The space station’s water recycling research has uncovered new facts about how bubbles and foam behave. This might seem distant from daily life, but it’s the same science that determines whether your shampoo lathers properly or your morning coffee has the right foam on top. By understanding how liquids and bubbles interact without gravity’s influence, scientists can develop better manufacturing processes for these everyday products.

What scientists call “superglass” – made by superheating metal oxides found in space rocks – could transform phone screens and car windows. Current phone screens crack easily because of tiny flaws that form during manufacturing. Space-based research shows how to reduce these flaws, potentially leading to more durable and less expensive screens.

The research team is also studying “soft matter” – materials that can change shape easily, like gels and creams. In space, these materials behave differently, revealing new ways to improve their stability and performance. This could lead to better cosmetics that don’t separate on the shelf and more effective drug delivery systems.

Each experiment builds on NASA‘s dual mission: advancing space exploration while solving Earth-bound challenges. While the research happens in space, the solutions it provides could improve products in homes and workplaces within the next few years.From a critical perspective, some challenges remain. The cost of implementing these space-based manufacturing techniques on Earth needs further study. Additionally, scaling up these processes from space station experiments to full industrial production will require significant engineering work.