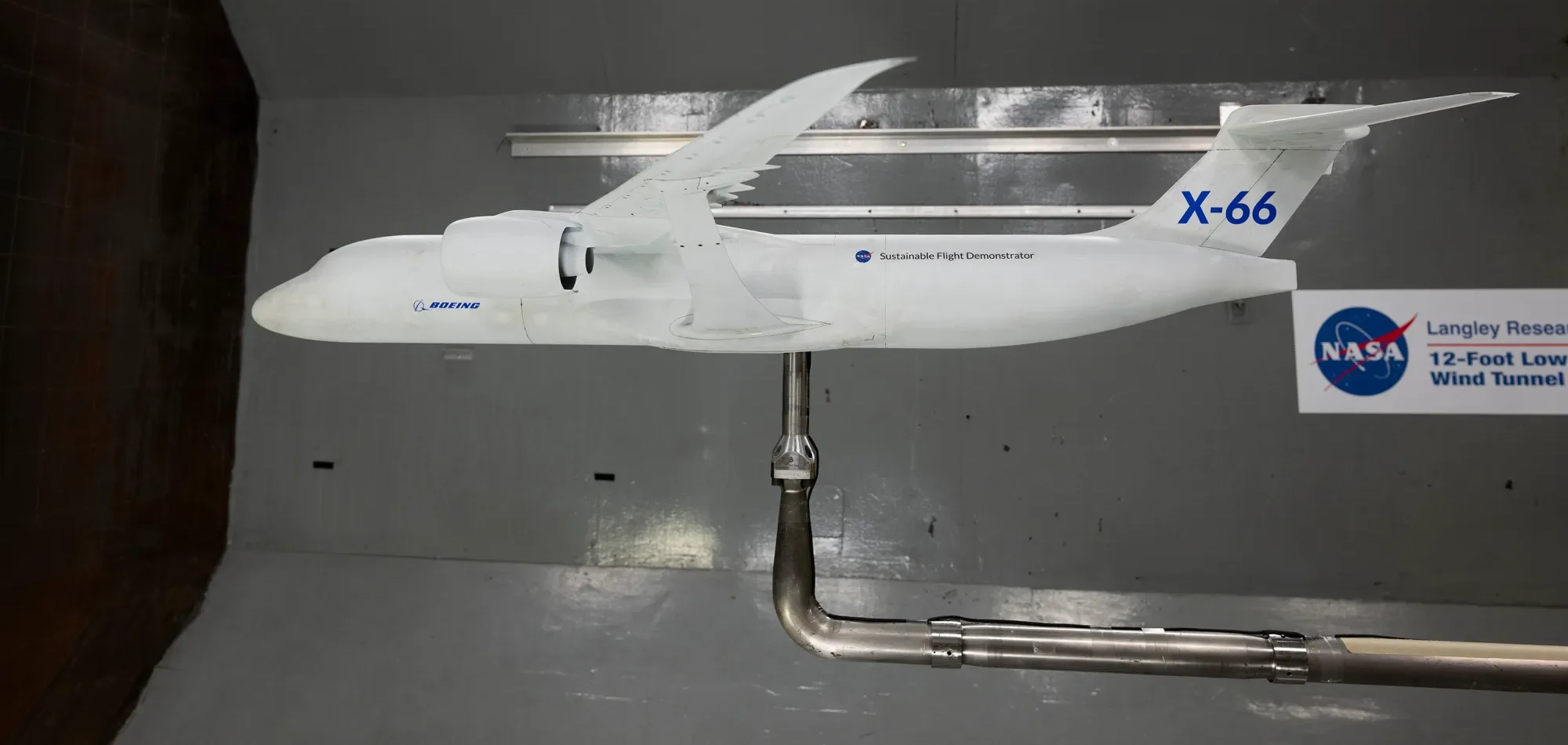

Wind tunnel tests of NASA’s X-66 aircraft model at Langley Research Center on October 30, 2024, mark a technical milestone for commercial aviation’s push toward sustainability. The 6-foot wingspan scale model underwent aerodynamic validation in NASA’s 12-Foot Low-Speed Wind Tunnel, measuring forces such as lift and drag across multiple aerodynamic configurations and flight conditions.

“Project team members are analyzing the data and using it to determine if design changes or adjustments are necessary for future wind tunnel tests,” stated NASA officials in their recent press announcement. These measurements will guide modifications before advancing to high-speed wind tunnel testing phases.

The X-66’s transonic truss-braced wing configuration employs diagonal struts connecting extended wings to the fuselage – a departure from conventional commercial aircraft design. This architecture could result in up to 30% less fuel consumption and reduced emissions when compared with today’s best-in-class aircraft, according to NASA.

The extra-long wing design stabilized with diagonal struts introduces new engineering considerations that require validation through comprehensive testing programs.

NASA’s pursuit of fuel-efficient aircraft designs includes previous experimental programs. The source material indicates past innovative designs like the blended-wing body (BWB) and double-bubble fuselage were explored, though the X-66 approaches efficiency through different means.

Commercial aviation currently generates 2% of global carbon emissions. A London-New York round trip produces carbon equivalent to one EU resident’s annual home heating, according to European Commission data. Single-aisle aircraft like the Airbus A320 and Boeing 737 serve as the workhorse of passenger airlines around the world.

More Stories

Boeing will modify an MD-90 aircraft that’s no longer in service into the X-66 demonstrator at their facility in Palmdale, California. The testing program includes:

- Aerodynamic performance measurements

- Multiple configuration testing

- Analysis of collected data

- Future high-speed wind tunnel testing phases

The project faces several areas requiring thorough validation:

- Aerodynamic performance across flight conditions.

- Design optimization through wind tunnel testing.

- Integration of the transonic truss-braced wing design.

- Validation of the extended wing configuration.

- Performance verification across testing phases.

The testing program generates essential data to validate the aircraft’s design characteristics.

NASA/Ryan Hill

While electric aircraft development continues for sub-300-mile routes, battery weight limitations prevent electric propulsion for longer commercial flights. The X-66’s aerodynamic innovations focus on improving efficiency for commercial passenger aircraft.

The Sustainable Flight Demonstrator (SFD) project represents NASA’s effort to develop more efficient airframes as the nation moves toward sustainable aviation. This project seeks to inform the next generation of single-aisle airliners, with Boeing and NASA partnering to develop the experimental demonstrator aircraft.