Construction is getting a surprising helper: dirt from the building site itself. MIT researchers have found a way to use 3D-printed mud to build concrete structures faster and cheaper than traditional methods.

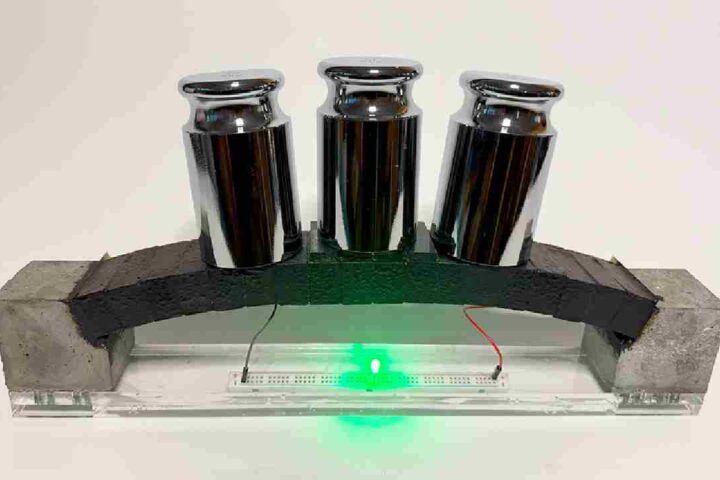

Currently, builders spend time and money creating wooden molds, then tear them down after the concrete hardens. MIT’s new method, called EarthWorks, uses treated soil instead of wood for these molds.

“We’re taking the ground we’re standing on and turning it into molds for concrete buildings,” explains Sandy Curth, who leads the research at MIT’s Department of Architecture. The team mixes construction site soil with straw and adds a special coating to keep the concrete’s moisture in place while it hardens.

The change could significantly impact construction costs and environmental protection. Concrete building creates 8% of the world’s carbon emissions. By using recycled dirt molds and smarter building shapes, EarthWorks can cut these emissions in half.

Similar Posts

The mud molds also allow for different building shapes. “We can make shape-optimized building elements for the same amount of time and energy it would take to make rectilinear building elements,” says Curth. This means buildings that use materials more efficiently.

Professor Caitlin Mueller from MIT explains why this matters: “This method brings better building design within reach for construction sites anywhere in the world, while keeping costs low and reducing carbon emissions.”

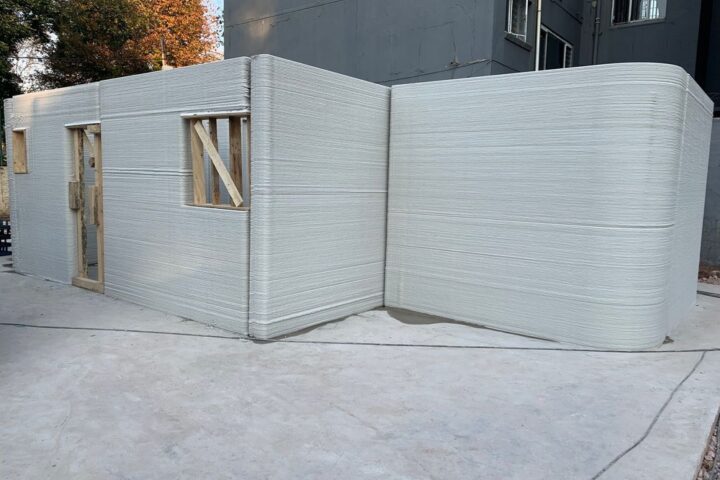

Curth has started a company, FORMA Systems, to bring this technology to construction sites. While builders would need large 3D printers, they’d save money on materials. The technology could eventually help build entire two-story homes using earth-based materials.

The research team published their findings in the journal Construction and Building Materials, with support from MIT’s urban research funding. Their work shows how combining old materials like mud with new technology can make building cheaper and more environmentally friendly.