A team of engineers at MIT is pioneering the potential reshaping of the aviation industry through the creation of a 1-megawatt motor that plays the role of a stepping stone in the process of electrifying larger aircraft. Unlike small gas turbine aero-engines, the megawatt motor can produce a massive one megawatt of power. Through the process of designing and testing the major components of the motor, as well as detailed computations the team has concluded that the motor can produce such power.

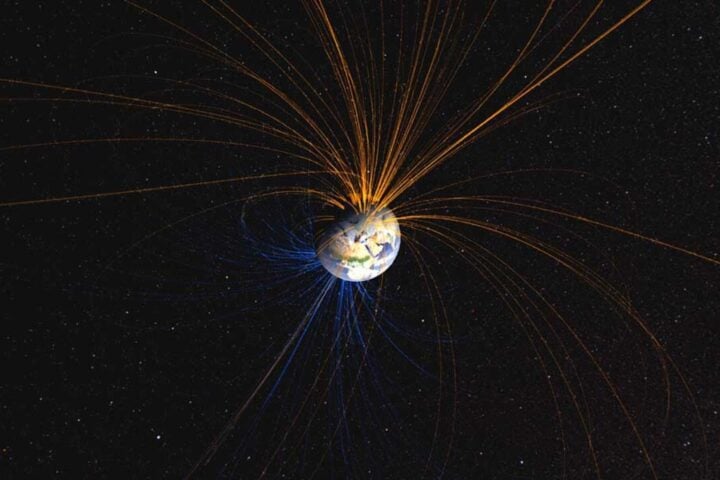

“No matter what we use as an energy carrier — batteries, hydrogen, ammonia, or sustainable aviation fuel — independent of all that, megawatt-class motors will be a key enabler for greening aviation,” asserts Zoltan Spakovszky, the project lead at MIT. The team at MIT has overcome the strict weight restrictions applied by the industry and developed a lightweight design for their motor. This opens the door to the development of larger aircraft being electrified. While the current energy density that modern batteries provide is not sufficient for long-distance air travel, development can lead to the achievement of global net-zero carbon dioxide emissions by 2050. To do this, Spakovszky states that areas such as unconventional aircraft design, advanced materials, efficient electrified propulsion, and smart fuel systems need to be focused on.

The creation of an electric motor capable of power and lightweight enough for large aircraft, as tackled by engineers of MIT, is not a simple procedure. There are several factors that are involved such as a complex, intricate balance of components, including thermal management, power electronics, structures, and rotor dynamics. Electrical machines face several challenges despite their long run of over a century and a half. There are numerous challenges in aviation due to their weight and heat generation, requiring innovative solutions for thermal management and weight reduction. “Heavy stuff doesn’t go on airplanes,” Spakovszky says, highlighting the necessity of compact, lightweight, and powerful motors. The team has meticulously arranged magnets within a titanium drum to achieve a high power-to-weight ratio, forgoing traditional heavy steel.

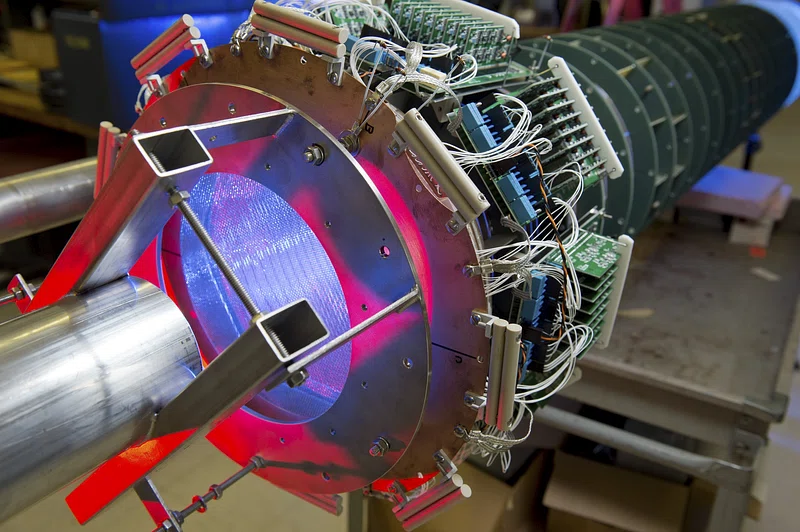

The team’s design incorporates a novel air-cooled heat exchanger for efficient thermal management, crucial in dealing with the immense heat generated by a 1 MW power output. Another key feature of the team’s design is a highly compact stator and a high-speed power electronics system composed of 30 custom-built circuit boards, enabling the motor’s incredibly high rotation speed. The design ensures minimal losses through transmission as well as closely coupling the distributed circuit boards with the electrical machine to enable effective air cooling. “This is a high-speed machine, and to keep it rotating while creating torque, the magnetic fields have to be traveling very quickly, which we can do through our circuit boards switching at high frequency,” explains Spakovszky.

Currently, the team has taken to assembling the first fully working electric motor and testing it by the end of the year. Phillip Ansell, director of the Center for Sustainable Aviation, comments on the project: “This group’s design uses a wonderful combination of conventional and cutting-edge methods for electric machine development, allowing it to offer both robustness and efficiency.” While powering regional aircraft, the team also envisions that their design could complement conventional jet engines, enabling hybrid-electric propulsion systems.

This foundation, led by engineers of MIT, will not only enable the creation of the one-megawatt electrical machine but also could be the groundwork for multi-megawatt motors, paving the way for larger passenger planes. “We are not electrical engineers by training, but addressing the 2050 climate grand challenge is of utmost importance; working with electrical engineering faculty, staff and students for this goal can draw on MIT’s breadth of technologies so the whole is greater than the sum of the parts,” Spakovszky remarks. This indicates the collaborative nature of the project. Other institutions, including NASA and the University of Illinois Urbana-Champaign, are also developing megawatt-scale electric motors, adding to the global momentum of greening aviation.

Similar Post

Battery technology in current times is still lagging, alternatives like hydrogen and ammonia are the upcoming candidates for powering future electric propulsion systems. According to Kiruba Haran, a professor of electrical and computer engineering, hybrid systems where electric motors are integrated with gas turbines could come into play sooner than full electric propulsion. Spakovszky alludes to a radical transformation in the aviation industry and also predicts that the future of the aviation industry will see unconventional aircraft configurations powered by multiple megawatt-class motors, replacing the traditional large jet engines. He posits that, “I believe, that to achieve net-zero emissions, future aircraft will have to look different, and megawatt-class electrical machines are key enablers for unconventional aircraft configurations,”