A breakthrough in aluminum recycling could help reduce industrial waste while meeting growing global demand for the metal used in everyday items from soda cans to smartphones.

Engineers at MIT have developed a special filter that captures and recycles aluminum from manufacturing waste, potentially saving thousands of tons of metal that would otherwise be lost. The filter can recover more than 99% of aluminum from industrial waste streams.

“This membrane technology not only cuts down on hazardous waste but also enables a circular economy for aluminum by reducing the need for new mining,” says John Lienhard, professor at MIT and director of the Water and Food Systems Lab.

The innovation comes at a crucial time. Aluminum production is expected to rise 40% by 2030, raising concerns about environmental impact. A single aluminum plant currently wastes about 2,800 tons of aluminum annually through a byproduct called cryolite waste.

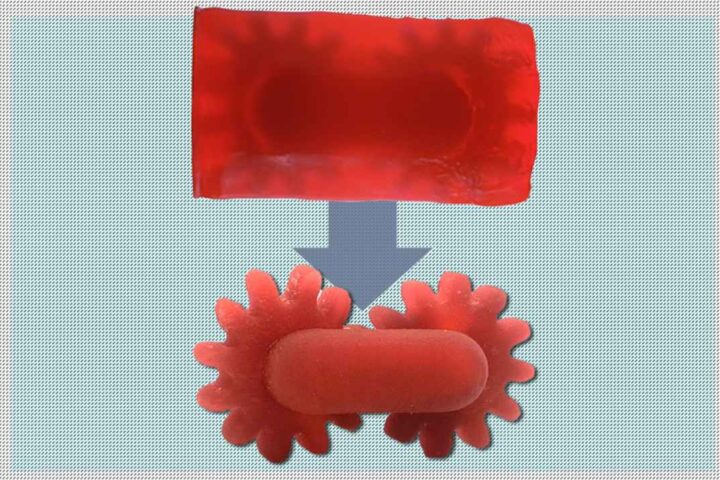

The new filter works like a selective sieve. It uses a positively charged coating that attracts and captures aluminum ions while letting other materials pass through. Think of it like a bouncer at a club who only stops specific people from entering – in this case, the aluminum ions.

Similar Posts

The technology has proven durable even in harsh industrial conditions. “We found the membrane works really well, even within harsh conditions that we would expect,” says researcher Zi Hao Foo.

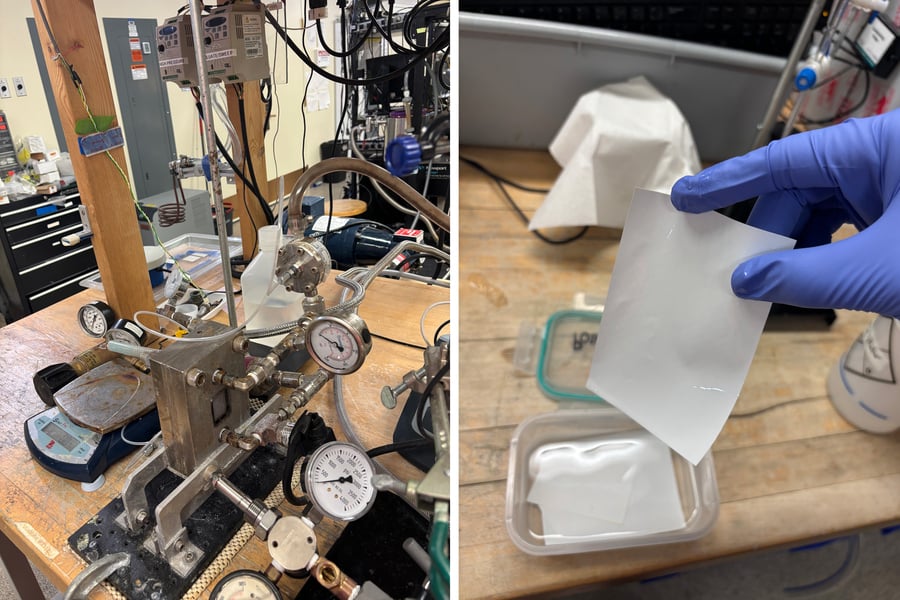

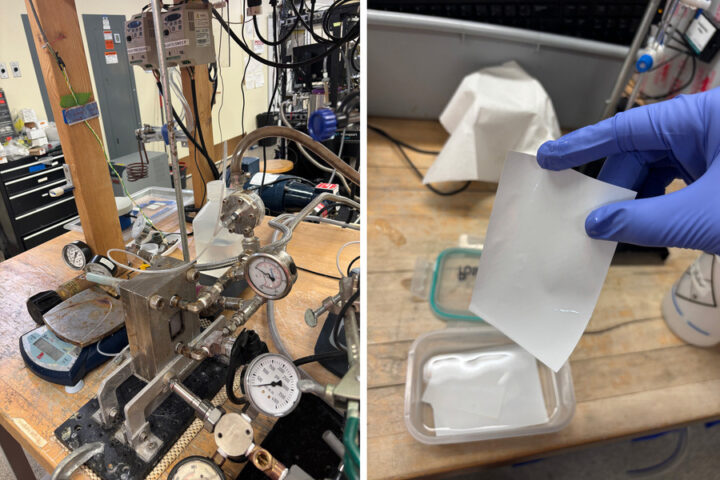

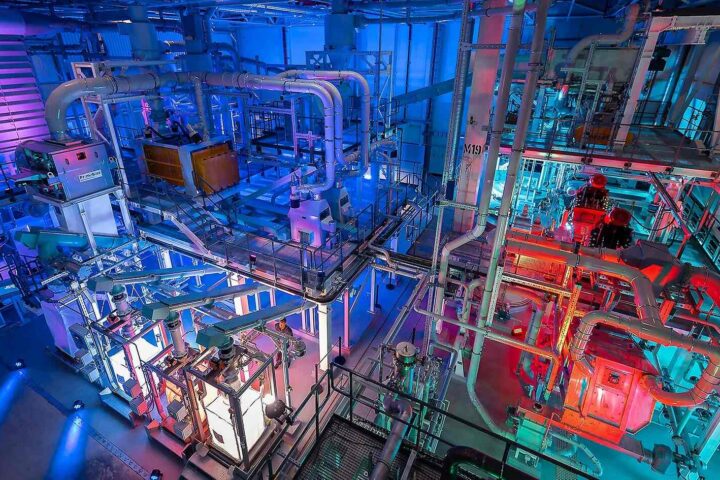

Currently, the experimental filter is about the size of a playing card. The researchers envision scaling it up similar to water treatment plants, where long membranes are rolled into cylinders for industrial use.

The practical benefits extend beyond the factory floor. By recycling aluminum back into production, manufacturers can reduce hazardous waste and lower the need for new mining. This technology offers a promising solution to address environmental concerns while meeting the growing demand for aluminum.

The research team worked with Japanese company Nitto Denko to develop the membrane. Their findings appear in the journal ACS Sustainable Chemistry and Engineering.

This development represents a step toward more sustainable aluminum production, though implementing it at industrial scale remains the next challenge. With aluminum’s growing role in everything from packaging to electric vehicles, such innovations could help balance industrial needs with environmental protection.