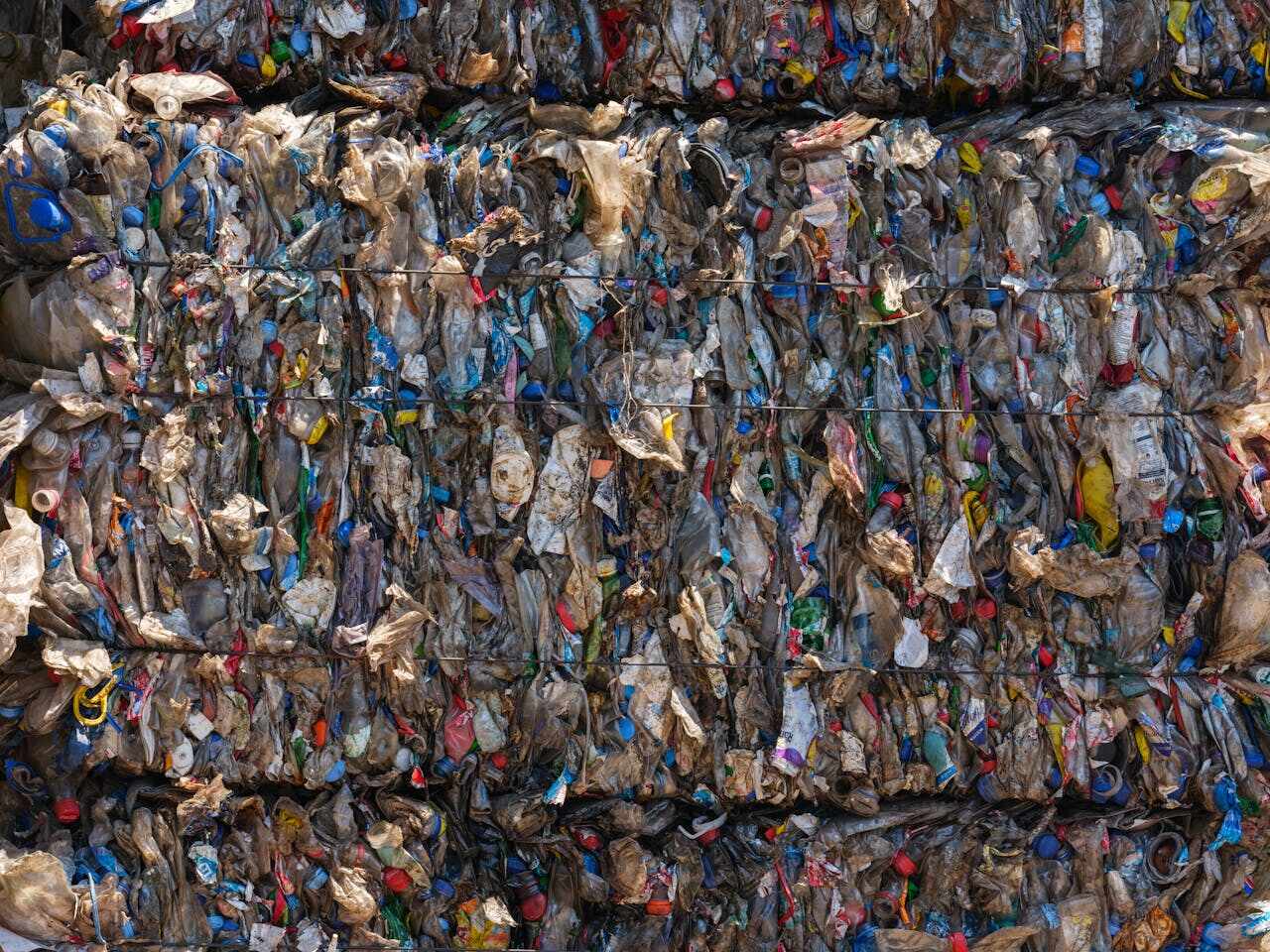

In an era where plastic waste management demands urgent solutions, LG Chem has established a commercial pyrolysis plant in Dangjin, South Korea. The facility, operating with a 20,000-ton annual capacity, employs supercritical pyrolysis technology to convert mixed waste plastics into raw materials.

Technical Innovation in Focus

The plant’s supercritical pyrolysis process operates at elevated temperatures and pressures, processing mixed waste plastics into pyrolysis oil. Technical data reveals conversion efficiency – from 10 tons of plastic input, the system generates 8 tons of pyrolysis oil. The remaining two tons emerge as by-product gas, which powers the facility’s operations.

Economic and Environmental Considerations

The Dangjin facility, while technically advanced, represents a new step in plastic recycling. The plant’s 20,000-ton capacity demonstrates LG Chem’s commitment to chemical recycling technology. The process addresses limitations of mechanical recycling, particularly in handling contaminated waste plastics.

Product Specifications

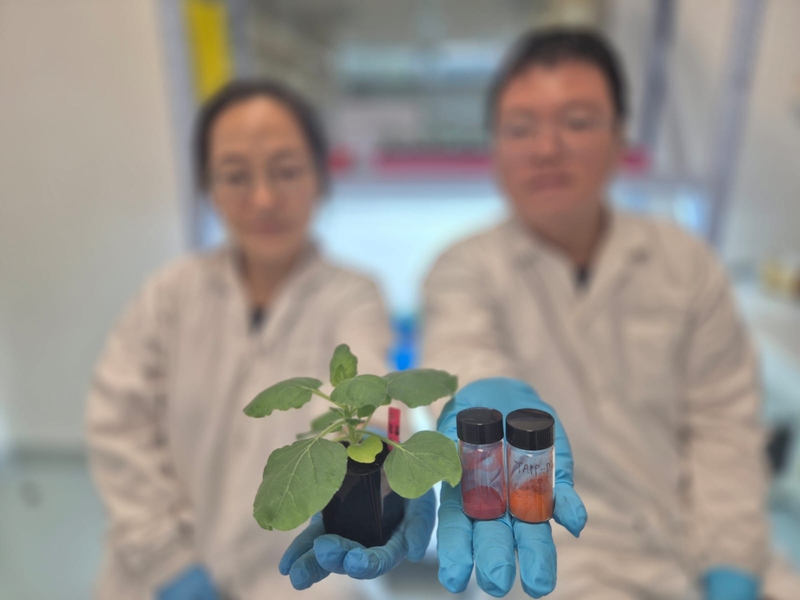

The facility produces “Circular Balanced,” a chemically recycled plastic product. Technical specifications indicate performance equivalence with conventional petrochemical-based products. The material holds ISCC Plus certification, allowing customization of recycled content percentages.

Technical Process and Applications

Chemical recycling through supercritical pyrolysis breaks down mixed waste plastics with supercritical water vapor at high temperature and pressure. Unlike other pyrolysis technologies that apply heat directly, it suppresses the production of carbon deposits during pyrolysis, enabling continuous operation without additional intervention.

More Stories

Market Context

The initiative aligns with growing global regulations mandating recycled content in plastics across industries, from packaging to automobiles. LG Chem’s approach to chemical recycling produces post-consumer recycled (PCR) materials including ABS, PC/ABS, PO, PVC, and PC.

Environmental Benefits

The process offers several advantages:

- Reduces environmental pollution

- Increases recycling rates of waste plastics

- Enables repeated recycling without quality compromise

- Processes contaminated waste plastics effectively

- Creates no waste plastic discharge in the system