General Motors (GM) has temporarily suspended production at two key U.S. factories in Texas and Michigan due to supply chain disruptions caused by Hurricane Helene. The automaker halted operations at its Flint Assembly plant in Michigan and Arlington Assembly plant in Texas on Thursday and Friday, impacting the production of highly profitable large pickups and SUVs.

Production Halt Details

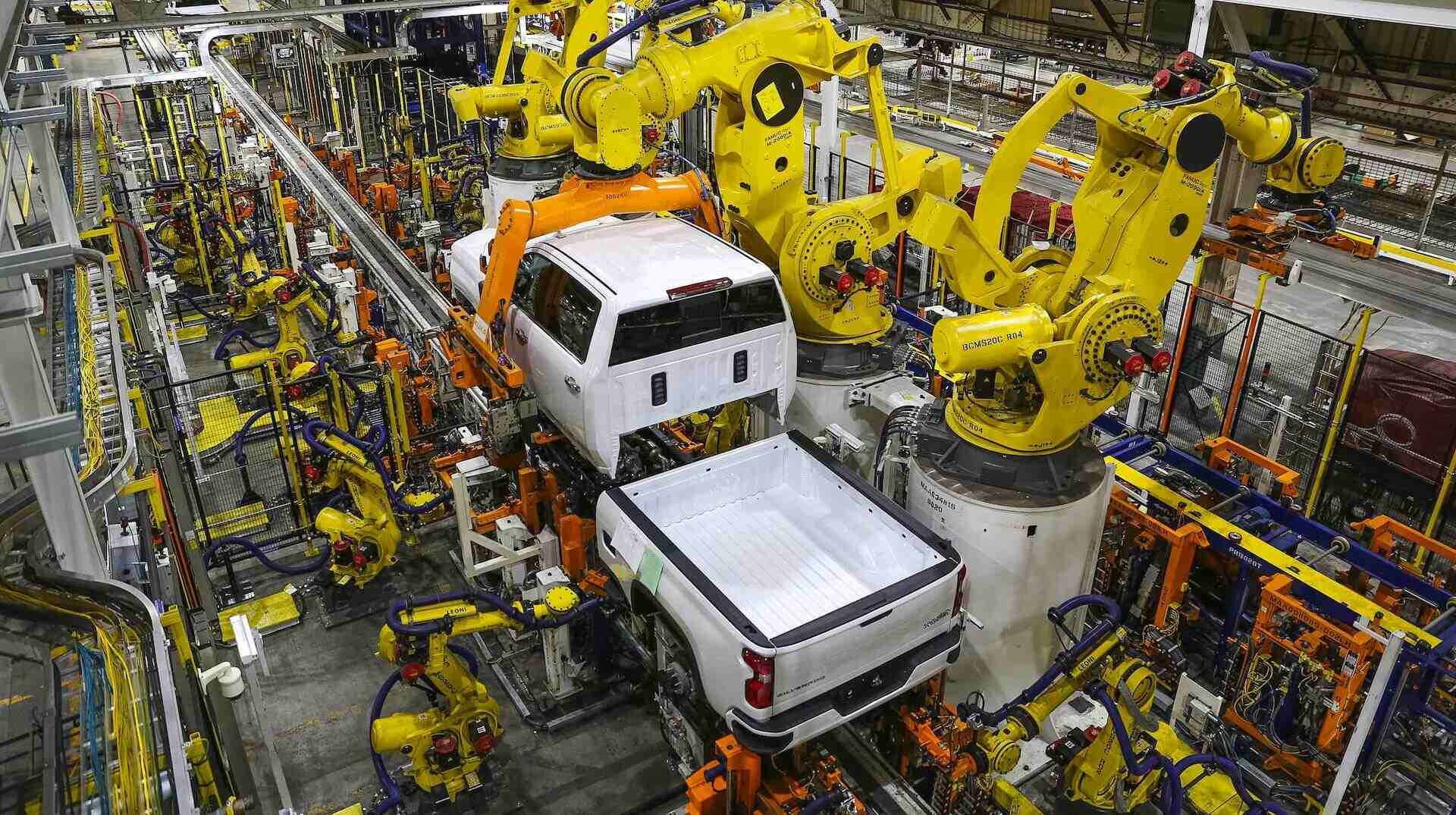

The Flint facility, responsible for manufacturing full-size heavy-duty Chevrolet Silverado and GMC Sierra pickups, sent first-shift workers home on Thursday. Second and third-shift employees were instructed not to report for the remainder of the week. In Arlington, where GM produces popular models like the Chevrolet Suburban, Tahoe, GMC Yukon, and Cadillac Escalade, regular assembly work is scheduled to resume soon.

GM spokeswoman Tara Kuhnen stated, “We are working with these suppliers to resume operations as quickly and safely as possible for their employees and communities as we seek to minimize impacts on our plants.”

Similar Posts

Supply Chain Impact

The production stoppage stems from Hurricane Helene’s effect on GM’s suppliers, particularly those located in North Carolina. While the GM plants themselves were unharmed, many supplier employees in the hurricane’s path are unable to work due to personal devastation.

Jeffrey Morrison, GM’s vice president of global purchasing and supply chain, told CNBC during an auto conference for the Rev. Jesse Jackson’s Rainbow Push Coalition in Detroit, “Covid really helped us map our value chain a lot deeper. Pre-Covid, understanding what the sub-tiers were was more difficult. We’ve got a great inventory of what those sub-tiers are now. Not only can we control the material we directly buy, we can talk to all of our suppliers”, as reported by Michael Wayland.

Economic Implications

The temporary shutdown affects more than 4500 employees at the Flint Assembly plant. While GM is mitigating their differences with UAW, the high profitability of the affected vehicle models, the production disruptions could result in significant financial losses for GM. Industry analysts estimate the daily revenue impact could reach into the millions of dollars.

Historical Context and Industry Impact

This is not the first time GM has faced production challenges due to natural disasters. Previous events, such as Hurricanes Katrina and Harvey, have led the automaker to enhance its disaster preparedness strategies. The current situation underscores the ongoing vulnerability of automotive supply chains to extreme weather events.

Supply Chain Resilience

Research indicates that natural disasters are becoming more frequent and severe, posing increased risks to global supply chains. Statistics show that such disruptions can lead to substantial economic losses, emphasizing the need for proactive measures in the automotive industry.

As GM works to resume normal operations, the incident serves as a reminder of the complex interconnections within the automotive industry and the ongoing challenges posed by climate-related events.