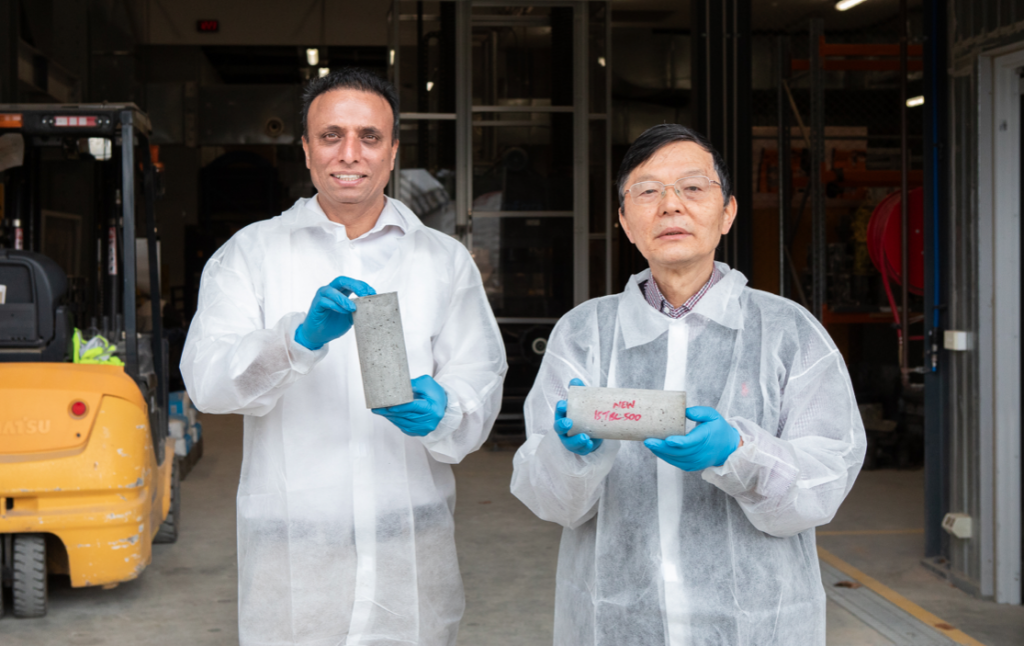

Specialists from a university in Australia used coffee grounds waste to modify the components used in concrete production, making it stronger and more eco-friendly. The creators of the coffee concrete went ahead and even used it to construct a footpath.

Previously, researchers from RMIT managed to create a sustainable material with 80% less cement and replace it with fly ash. Now they have stepped up a notch further and touched upon one more waste byproduct, coffee waste, that can become a valuable resource used as a part of a circular economy.

To make concrete, it’s necessary to mix sand and gravel with cement and water, but, unfortunately, this construction material is responsible for about 7% of greenhouse gas production, according to the United Nations (UN).

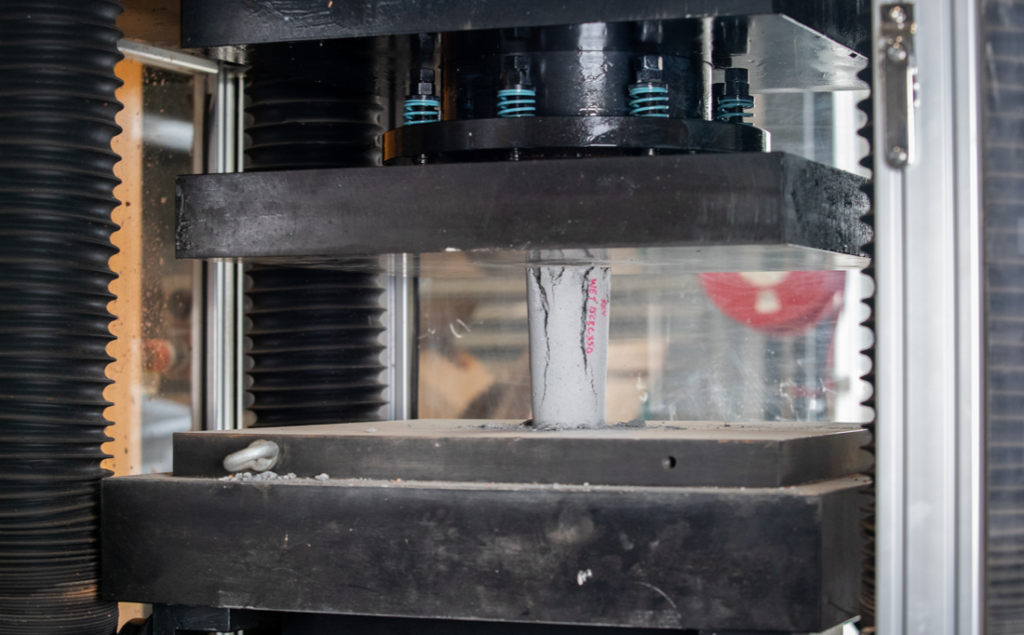

The addition of biochar makes the concrete 30% stronger and reduces the amount of cement needed by up to 10%. According to a 2022 UN report, around 50 billion metric tons of sand are extracted each year, mainly for concrete production. Its extraction is often environmentally destructive and is becoming increasingly scarce. Cement production, which involves heating a mixture of limestone and clay to about 1,500 degrees Celsius, is responsible for most of the emissions from concrete.

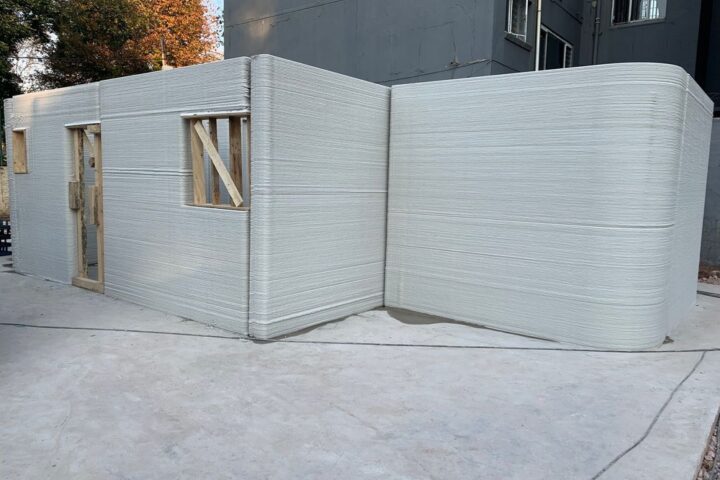

Australians generate 75 million kilograms of ground coffee annually. Instead of landfills, it could be handy to replace up to 655 million kilograms of sand in concrete because of its denser material properties. So now that footpath in Macedon Ranges Shire Council will become a gentle reminder to citizens about the many ways we can make our planet a better place to live in.

“Despite the fact that we’re using coffee grounds or mulch, residents aren’t going to really see or smell any difference in this concrete product,” explained Shane Walden, Council’s Director of Assets and Operations. “It also has lots of other benefits and benefits that are important to our community. This includes helping the environment, acting sustainably and, most importantly, reducing waste to landfill and having a circular economy, ” he added.

Similar Post

RMIT researchers are in talks with construction companies, cement manufacturers, and a coffee chain to utilize coffee bean waste and establish a company dedicated to producing biochar. Australian infrastructure company Bild Group said it planned to test the concrete and hoped to use it in large road projects. Construction giant Arup supported the research.

Meanwhile the researchers would use the time to test the concrete, see how it performs over time, and use it for future applications.

“We are currently working in the supply chain sector so that we can make this research into a mainstream product for commercial applications, and we’re not only looking into coffee – we’re expanding this into all forms of different organic waste,” noted Roychand. “Every biochar produced from a different organic material comes with varying composition, in addition to the difference in carbon content, particle size and absorbency, that can boost the performance of concrete in a range of ways,” he added.