Georgia Tech researchers have developed a simplified approach to direct air capture (DAC) systems.

Their method utilizes ambient wind flow to draw air across sorbent-coated carbon fibers, eliminating the need for loud fans. The carbon fibers can quickly release captured CO2 with minimal heat loss, improving efficiency.

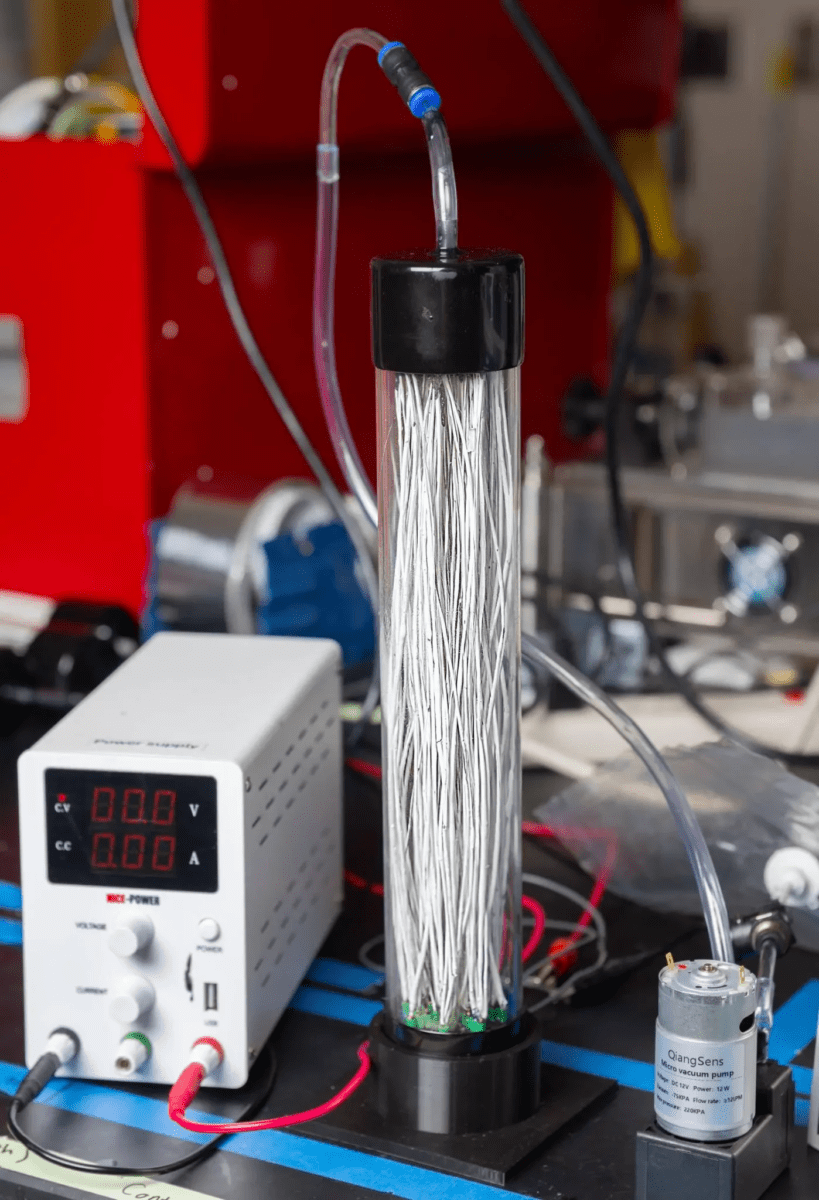

The researchers found that deploying the fibers in a design inspired by pneumatic bank tubes proved successful. The team’s DAC system could produce carbon dioxide with sufficient purity for underground sequestration. The upfront costs of their system are significantly lower compared to typical DAC systems.

The projected cost of capturing CO2 with their system is $150 to $200 per ton. This technology could help mitigate the climate crisis by making the air cleaner.

The carbon fiber tubes are quiet, efficient, and don’t require noisy fans to operate. The system’s use of renewable energy, such as wind power, could enhance its effectiveness. ETH Zurich scientists have achieved optical terabit data transmission through the air, opening possibilities for faster backbone connections.

The Georgia Tech researchers’ DAC system offers two key advances in CO2 release and capture. Their carbon fiber strands coated with a carbon-loving sorbent allow for fast and even heat distribution.

The system uses fewer components overall and doesn’t require steam generators or pumps. The capital cost of their DAC system is significantly lower due to the absence of auxiliary systems like steam generation. The rapid heating and fast cycling of the system hold promise for a more productive approach to direct air capture.

Similar Post

Ideally, the DAC system could be integrated with a wind farm to utilize renewable energy. Even with power from the current grid, the team’s design can still achieve carbon negative results. The carbon fiber strands have the right mechanical and electrical properties for effective CO2 capture.

The inexpensive material is readily available and sustainably manufactured.

The team aims to increase the purity of the captured CO2 for productive reuse, like making chemicals or fuels. They have achieved 80% purity thus far, making them suitable for underground storage. Working with the Georgia Tech Research Institute, the team seeks to refine and automate their system for improved CO2 quality.

A test system will be installed atop a campus building to further evaluate the technology. The researchers’ approach expands the array of design options for DAC technology developers. The technology offers a more cost-effective and efficient method for capturing CO2. Georgia Tech is positioned as a leader in direct air capture technology, with researchers working on various aspects of DAC systems.