In an effort to address the global plastic pollution crisis, a team of researchers at the University of Washington (UW) have made a significant breakthrough. They have developed a unique bioplastic from spirulina, a type of blue-green algae, which shows promising potential as a feasible alternative to petroleum-based plastics due to its comparable characteristics.

A distinguishing feature of this innovative material is its ability to biodegrade in backyard compost conditions, swiftly decomposing similar to a banana peel. This stands in contrast to many traditional bioplastics that necessitate commercial composting facilities. Spirulina, known for its use in foods and cosmetics, lends itself favorably to large-scale cultivation of this bioplastic, due to its wide availability and carbon-neutral properties.

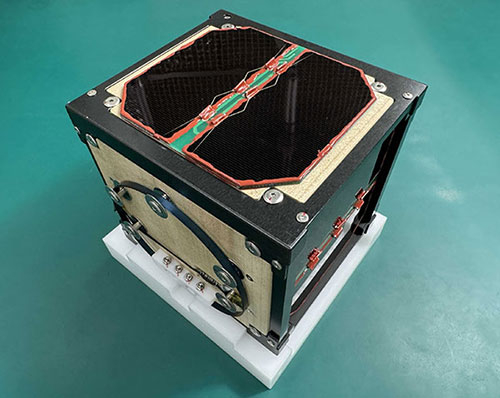

The spirulina-based bioplastic captures carbon dioxide during its growth phase, presenting itself as a promising solution to reduce greenhouse gases. Interestingly, this bioplastic also exhibits fire-resistant properties, a trait that is often absent in conventional plastics. When exposed to flames, it self-extinguishes, which opens up potential application in areas where traditional plastics are risky due to their flammability, such as server racks in data centers.

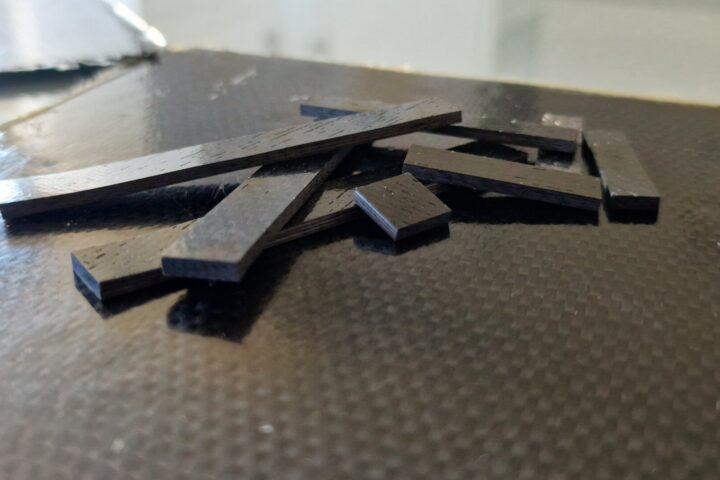

The team at UW achieved a key breakthrough in the development of this bioplastic – its processability and scalability. By employing heat and pressure to mold the spirulina powder, the process mirrors conventional plastic production. This method allows existing production lines to be used, eliminating the need for expensive infrastructure changes.

Significantly, these spirulina-based bioplastics demonstrate mechanical strength and stiffness up to ten times greater than previously reported spirulina bioplastics. Owing to its enhanced durability and strength, it emerges as a viable candidate for various applications, ranging from disposable food packaging to everyday household items like bottles and trays.

Despite its strengths, the bioplastic does show sensitivity to moisture, posing a challenge to its wider application. The research team at UW is actively investigating these limitations, with the aim of refining the material’s properties for diverse usage.

“Spirulina also has unique fire-resistant properties. When exposed to fire, it instantly self-extinguishes, unlike many traditional plastics that either combust or melt. This fire-resistant characteristic makes spirulina-based plastics advantageous for applications where traditional plastics may not be suitable due to their flammability. One example could be plastic racks in data centers because the systems that are used to keep the servers cool can get very hot.”

– Hareesh Iyer, UW Materials Science And Engineering Doctoral Student

Similar Post

In terms of end-of-life scenarios, the new bioplastics are environmentally friendly, being recyclable through mechanical means. If not recycled, they degrade quickly, significantly reducing their environmental impact. This development has piqued the interest of tech industry leaders like Microsoft and Meta, who have extended financial support for the research, signaling a growing interest in sustainable materials.

The research findings have been published in the scientific journal, Advanced Functional Materials, which underscores the academic significance of this innovative development. The material’s brittleness presents a challenge for broader applications, requiring further research and optimization, despite its exciting potential.

The researchers at UW aim to create a spectrum of bioplastics, not dissimilar to the variety of existing petroleum-based plastics, tailored for a myriad of use scenarios. This breakthrough at UW presents an undeniable case for the vast potential of algae as a raw material for the creation of sustainable, biodegradable plastics.

This research is in alignment with global efforts to transition away from reliance on fossil fuels, steering towards more sustainable and environmentally friendly materials. Highlighting the crossover between sustainability and technology, Microsoft has shown interest in the UW-developed bioplastic for potential application in their cloud data centers.

“We were motivated to create bioplastics that are both bio-derived and biodegradable in our backyards, while also being processable, scalable and recyclable. The bioplastics we have developed, using only spirulina, not only have a degradation profile similar to organic waste, but also are on average 10 times stronger and stiffer than previously reported spirulina bioplastics. These properties open up new possibilities for the practical application of spirulina-based plastics in various industries, including disposable food packaging or household plastics, such as bottles or trays.”

- Eleftheria Roumeli, UW Assistant Professor Of Materials Science And Engineering

- Meta’s substantial donation to the UW lab accentuates the growing recognition of green materials within the electronics industry. Future applications of the bioplastic may extend to a diverse range of products, from home furnishings to food containers.

However, the process of commercializing this bioplastic still confronts challenges, primarily its poor resistance to moisture, a hurdle the UW team is diligently addressing. Despite the obstacles, the development of this bioplastic marks an encouraging stride towards mitigating the environmental damage caused by plastic pollution.