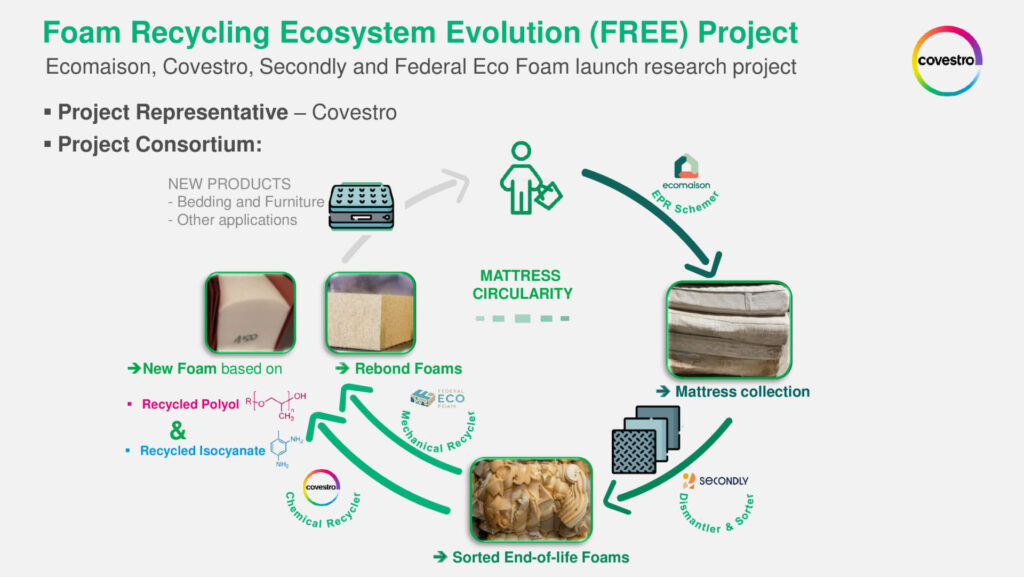

A consortium of four European companies made up of Ecomaison, Covestro, Secondly, and Federal Eco Foam has together launched a research project to recycle foam mattresses. The goal of the partners is to recycle foam from old mattresses as efficiently as possible by combining mechanical as well as chemical technologies. Their project is launched under the name “Foam Recycling Ecosystem Evolution” (FREE).

A careful sorting of the foam types in mattress cutting plants is crucial for this. The French company Ecomaison is dedicated to collecting and recycling old furniture and has been collaborating with Covestro for several years to utilize Covestro’s chemical recycling technology for this purpose. This process can recover both of the originally used raw materials – polyol and the precursor to isocyanate TDI.

Secondly is a the French dismantling company and Federal Eco Foam, a Belgian specialist in the mechanical recycling of flexible foams. The FREE project is planned to last a maximum of 24 months. The project is coordinated by Covestro and half-funded by Ecomaison.

The motivation for the FREE consortium lies in the added value of the material that can be recovered from the used foams and the opportunity to transition to a more sustainable circular economy. The partners want to explore all possibilities in a future-oriented foam recycling ecosystem and are convinced that chemical and mechanical recycling will complement each other effectively. As a specialist in disassembly and sorting, Secondly is interested in improving its sorting processes to deliver a specific foam quality to recyclers.

Similar Post

At the same time, the project will provide a good idea of what the foam recycling market might look like in the coming years. The partners are firmly convinced that chemical and mechanical recycling can complement each other well, given the different specifications of the raw materials already sorted during disassembly. To add value to the PU foam, the consortium will explore all possibilities in a forward-looking foam recycling ecosystem.

The research and development project involves foam sorting during disassembly as well as a comparative feasibility study for two recycling processes for the sorted foams, considering the economic and ecological value creation.

“Material efficiency is the key objective when creating a new material cycle for flexible polyurethane (PU) foam from used mattresses,” notes Covestro. With their current advancement, “the research and development project includes the foam sorting at the dismantling step, as well as a comparative feasibility study for two recycling processes for the sorted foams covering economic and ecologic value co-creation.”

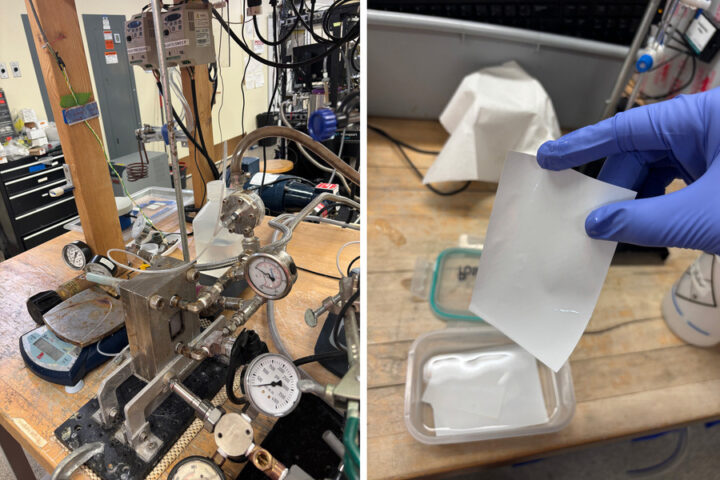

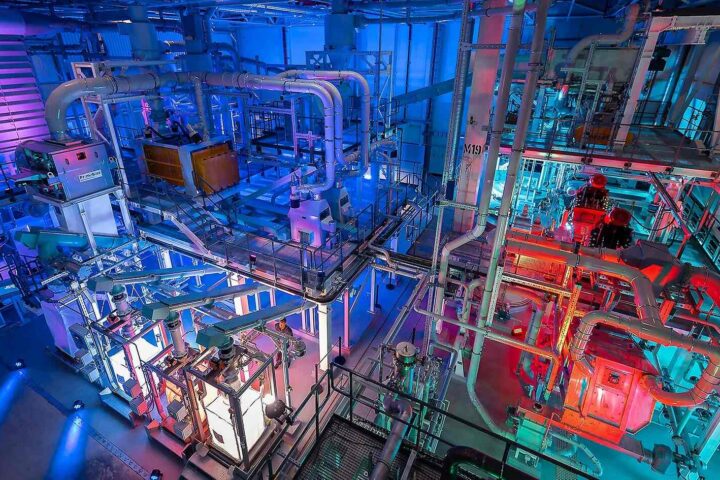

Several years ago, Covestro and its partners developed a chemical recycling process that is the only one of its kind capable of recovering both main raw materials for PU flexible foams in high purity. To this end, the company also operates a pilot plant at its Leverkusen site in Germany. Together with the waste management industry, the company aims to advance the process to industrial use.”To make its vision of a fully circular economy a reality, Covestro is making the development of innovative recycling technologies a priority and calls the evolution of recycling Evocycle® CQ. The chemolysis of PU mattress foam is the first initiative of Covestro of its kind and is called Evocycle® CQ Mattress,” concluded Covestro in their statement .