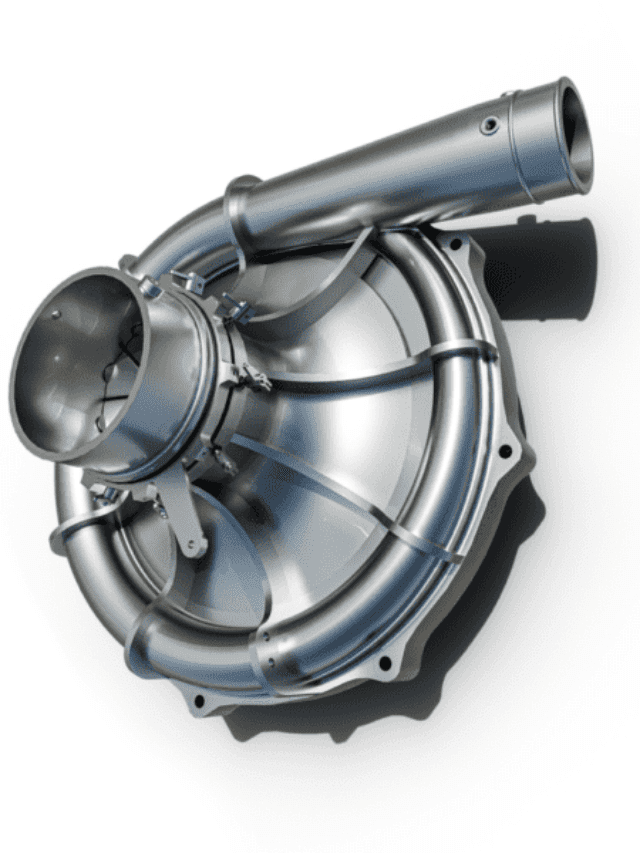

ZeroAvia has pioneered the development of the world’s first fuel cell compressor designed explicitly for aviation, marking a significant leap towards hydrogen-electric flight. This innovative compressor manages oxygen flow without the need for a separate electric motor, simplifying the certification process. By eliminating the additional electric motor, the compressor not only reduces weight but also enhances in-flight reliability. One of the primary challenges of using hydrogen fuel cells for aviation is ensuring a high oxygen flow, especially at elevated altitudes. ZeroAvia’s engineers have crafted a method to manage this oxygen flow, eliminating the need for a separate electric motor.

ZeroAvia’s ZA600, their inaugural hydrogen-electric powertrain, has demonstrated consistent performance across various power levels during initial testing. The company’s upcoming compressors will be integral to their first two hydrogen-electric engines: the ZA600 and the ZA2000. The ZA600, tailored for 9-19 seat aircraft, is projected to be operational by 2025. Meanwhile, the ZA2000, designed for 40-80 seat aircraft, is set to enter service by 2027. ZeroAvia’s overarching powertrain promises substantial commercial and environmental benefits for airline operators.

The company’s partnership with Masdar aims to explore hydrogen production and supply at pivotal locations. Initially, the collaboration will focus on projects in North America and Europe, with potential expansion to the UAE. Masdar, the UAE’s flagship renewable energy company, is on a mission to become a global leader in green hydrogen. By 2030, Masdar aims to produce one million tonnes of green hydrogen annually. Masdar’s Green Hydrogen division is deeply involved in major aviation projects targeting green hydrogen production. The UAE has ambitious plans, aiming to produce 1.4 million tonnes of hydrogen annually by 2031, with a tenfold increase projected by 2050.

Similar Posts

ZeroAvia’s compressor technology is poised to revolutionize high-power and high-altitude transport applications. The company is set to commence certification testing for the compressor within the next year. ZeroAvia has already secured pre-order agreements for nearly 2,000 engines from major airlines like American, United, and Alaska. The company’s recent collaboration with Alaska Airlines focuses on converting a Bombardier Q400 turboprop into a hydrogen-electric propulsion system. This strategic move aims to harness the full potential of zero-emission flights. ZeroAvia’s vision is to develop a powertrain for the Dash 8-400 that’s five times more potent than any previous demonstration. The company’s commitment to zero-emission flight has led to various groundbreaking projects. ZeroAvia recently completed a flight test campaign for the ZA600 engine aboard a Dornier 228 aircraft.

Masdar’s CEO, Mohamed Jameel Al Ramahi, expressed excitement about collaborating with ZeroAvia to advance decarbonization in challenging sectors like aviation. Val Miftakhov, ZeroAvia’s Founder and CEO, emphasized the need for substantial renewable energy investments to accelerate a future of genuinely clean flight for the entire aviation industry.

The compressor technology we have designed is critical in delivering optimal performance in the final, certified ZA600 engine technology. Our compressor is an important component of our fuel cell power generation systems, and a world-leading technology advancement for clean aviation in its own right. This really is a major achievement for our turbomachinery engineers and another marquee moment for the company at large.

Val Miftakhov, ZeroAvia’s Founder and CEO