Kawasaki is the main driving force behind the “Hydrogen Small Mobility & Engine Technology,” an association founded by the brand, which has brought together giants like Suzuki, Toyota, Honda, and Yamaha. The company aims to promote the research and development of hydrogen internal combustion engines. Globally, Japan aspires to become a global leader in the use of hydrogen, and Kawasaki is at the forefront of this effort, making the necessary moves. The HySE motorcycle project began in March of last year, with testing starting this year.

The motorcycle comes with a 998 cc supercharged inline four-cylinder engine, offering performance comparable to traditional engines. Modifications were made to the engine to allow direct hydrogen injection into the cylinders, and the chassis was adjusted to accommodate the tanks and an integrated fuel supply system. The motorcycle’s design includes hydrogen fuel bottles or tanks that store the hydrogen. The chassis can also house a hydrogen fuel system, which is the assembly that delivers the hydrogen from the tanks to the internal combustion engine. Kawasaki uses the engine from its Ninja H2 motorcycle for this vehicle, which has been adapted to transport and use hydrogen.

The most important feature is that hydrogen’s combustion in these engines produces water vapour emissions, with only a minimal amount of carbon dioxide. That small amount results from the combustion of the engine oil. Kawasaki is currently in the research and development phase, with the ambition of launching a hydrogen motorcycle on the market by the 2030s. The manufacturer says that the timing of commercial availability may vary depending on the hydrogen fuel supply infrastructure and the state of legal regulations in each country.

On July 20th, Kawasaki conducted the world’s first public demonstration of its motorcycle with a hydrogen internal combustion engine (ICE) at the Suzuka Circuit in Japan. During its first public demonstration worldwide in Japan, the manufacturer pointed out that its main byproduct is water, which is released in the form of steam. This makes hydrogen engines much cleaner as compared to gasoline engines, which emit pollutants like CO2, carbon monoxide, and nitrogen oxides.

Similar Posts

When the rider accelerates by twisting the throttle, Kawasaki’s hydrogen ICE motorcycle still roars and vibrates, despite not using conventional fuel. This is because the engine mechanics and combustion process are similar to those of a gasoline engine. Kawasaki admits that during the demonstration, a small amount of engine oil is burned along with the hydrogen however, they add that this only results in small amounts of CO2 production. Even so, they claim that the total emissions are significantly lower than those of traditional gasoline engines

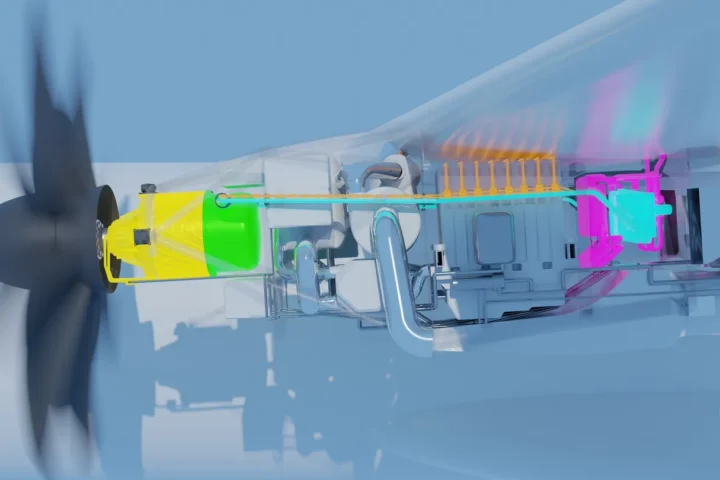

Technical Operation of a Hydrogen Internal Combustion Engine Motorcycle: A motorcycle with a hydrogen internal combustion engine (ICE) operates similarly to a traditional gasoline engine but uses hydrogen as fuel instead of gasoline. The following describes the detailed technical process:

- Hydrogen Storage: Hydrogen is stored in high-pressure tanks, usually in gaseous form. These tanks are designed to be safe and lightweight, integrating into the motorcycle’s chassis.

- Hydrogen Injection: The motorcycle’s injection system has been modified to handle hydrogen instead of gasoline. Hydrogen is directly injected into the engine cylinders through special injectors. The injection can be direct (Direct Injection, DI) or indirect (Port Fuel Injection, PFI), with DI being more efficient in terms of performance and emissions.

- Hydrogen and Air Mixture: In the cylinder, hydrogen mixes with air. This mixture is crucial for combustion, as hydrogen, being highly flammable, requires a precise ratio of air to burn efficiently.

- Combustion Process: Once the hydrogen and air mixture is in the cylinder, it is compressed by the piston moving upward. At the peak of compression, a spark plug generates a spark that ignites the mixture. The combustion of hydrogen produces an explosion that pushes the piston downward, generating mechanical motion.

- Power Cycle: The piston’s movement is converted into rotary motion through the crankshaft. This cycle of compression, combustion, and expansion is repeated in each engine cylinder, providing the power needed to move the motorcycle.

- Emissions: The main byproduct of hydrogen combustion is water vapour (H₂O). Unlike gasoline engines, no significant emissions of CO₂, CO (carbon monoxide), or nitrogen oxides (NOx) are produced. However, there may be traces of CO₂ due to the burning of small amounts of engine oil.

- Engine Management System (ECU): The engine control unit (ECU) has been reprogrammed to manage the specific characteristics of hydrogen, such as its high flammability and air-fuel mixture control. The ECU adjusts the amount of hydrogen injected and the timing of ignition to optimise efficiency and minimise emissions.

Benefits and Challenges:

- Benefits:

- Reduced Emissions: Emissions of harmful gases are significantly lower compared to gasoline engines.

- Clean Energy Source: Hydrogen can be produced from renewable sources, making the process more sustainable.

- Challenges:

- Hydrogen Storage and Transport: Requires specific infrastructure and advanced technologies to safely handle hydrogen at high pressure.

- Cost and Availability: The production and distribution of hydrogen are still expensive and limited in many regions.

In summary, a motorcycle with a hydrogen internal combustion engine is an innovative and more eco-friendly alternative to traditional engines, representing a significant advancement in sustainable mobility.