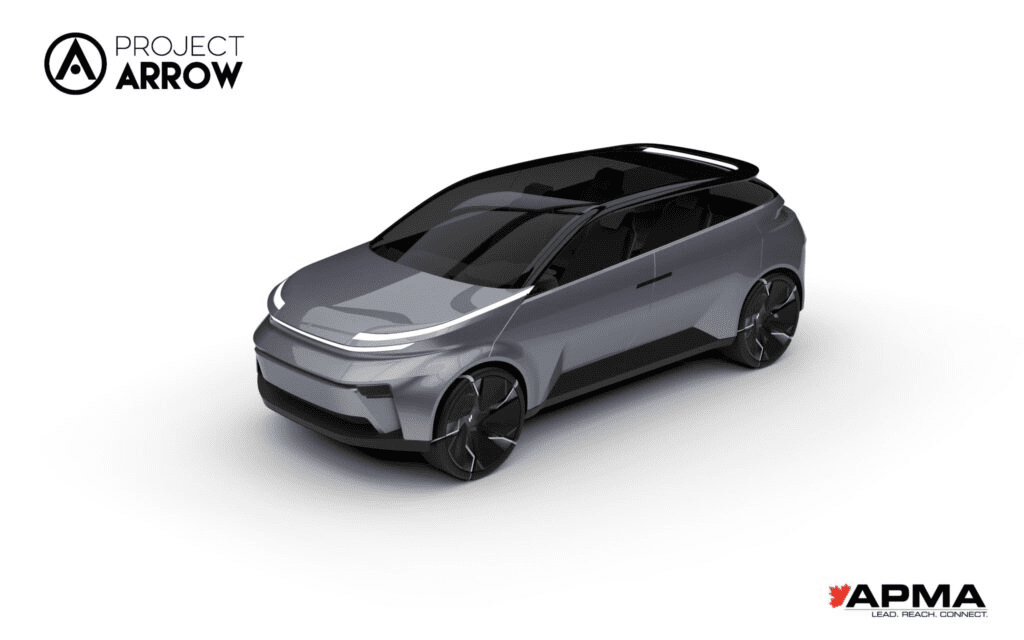

Project Arrow is a prototype of a fully functional 3D-printed electric car chassis, unveiled at the 2023 Consumer Electronic Show (CES) by the Automotive Parts Manufacturers’ Association (APMA), Canada’s national association representing service manufacturers for the global automotive industry. The car features an 82.5-kWh lithium-ion battery powering two motors, providing all-wheel drive, with an estimated 550 horsepower output, a race to 62 miles per hour projected to take 3.5 seconds, and an estimated range figure of 310 miles. Project Arrow has no plans for mass production but serves as a showcase for the suppliers who intend to sell real parts to automakers, demonstrating the technical know-how and people required to make electric vehicles in Canada successfully. Xaba, a Toronto-based software, engineering, and robotics startup, constructed the 3D-printed composite chassis using specially constructed composites from Dartmouth-based Meta Materials. Meta Materials won a CES 2023 innovation award for Nanoweb separate from Project Arrow. The technology used is capable of being used for electromagnetic interference (EMI) shielding, deicing, defogging, and other automotive applications.

The innovative car was unveiled by APMA, and it is for all intents and purposes a sleek electric SUV with a big feature: it has been 3D printed. Project Arrow is headed for a Canadian and U.S. roadshow this year, with plans to attend the Detroit and Los Angeles Auto Shows and visits to OEMs to demonstrate the tech involved. This prototype has a long life ahead of it as well, as Flavio Volpe, the head of APMA, stated that he would like to see the crossover updated with new versions as new technologies are ready for the market. The APMA worked with 50 suppliers, but 200 raised their hands. “In the end, we’re building one car,” Volpe said, “we probably could have built four.”

Canada is unlikely to be the first country to pop up in a conversation about electric car parts or 3D printing, but Project Arrow could change that. Project Arrow is a concept car, but some of the parts will end up in the next generation of electric vehicles as the global auto industry pivots into new technology. The APMA pledged to show the car at CES 2023, and it was successful on time, under budget, and with 97% homegrown content. Project Arrow is engineered to meet Canada’s safety regulations for road legality with commercially ready parts that can be built in quantity on an assembly line.

- Crater Lake Newt Drops to 13 as Crayfish Take 95% Shoreline, Lawsuit Targets ESA Delay

- Ford Stops U.S. Vehicle Exports to China as Tariffs Spike to 150% in Escalating Trade War

- Sterile Processing Technician: $70K Salary, 6% Job Growth, No Degree Needed

- Scientists New Color Olo Only Shows Up When a Laser Hits One Eye Cell Most People Never Notice

- NYC Congestion Toll Cuts Traffic by 1M Vehicles; Trump Sets April 20 Deadline

The automotive industry is quickly changing, and the use of 3D printing in the sector is becoming more prominent. Everyone is elbowing for a piece of the action, including Canadian auto parts suppliers. Xaba is a Toronto-based software, engineering, and robotics startup that emerged from stealth only last October. Xaba’s Intelligent Machine spit out the chassis using specially constructed composites from Dartmouth-based Meta Materials. The technology used is called Nanoweb, supposedly capable of being used for a range of other automotive applications. Project Arrow could be the game-changer for Canadian car parts suppliers in the new era of electric cars. It serves as a demonstration of the technical know-how and people required to make electric vehicles in Canada successfully. The car of the future, a 3D-printed electric SUV, has arrived.