In the world of wind power, the fight against ice has found an unlikely ally in drones. Traditionally, icy conditions on wind turbines have been a costly headache for operators, often leading to days of downtime. But, a team from Fraunhofer IFAM and IPA has developed a drone-based solution, aptly named “TURBO,” to tackle this issue.

The crux of this innovation lies in a simple yet effective idea: use drones to apply a special coating to the rotor blades, preventing ice formation. The coating, a concoction of urea and wax, is environmentally friendly and adheres well to the blades. Its application is a feat of precision, executed by drones equipped with a lance that sprays the material with pinpoint accuracy.

Andreas Stake, project manager at Fraunhofer IFAM, emphasizes the cost-effectiveness of this solution. Compared to traditional methods like heating mats or helicopters, drones are a more economical choice. But the process wasn’t straightforward. The team had to ensure the material’s durability, the spraying system’s precision, and the drones’ payload capacity.

Similar Posts

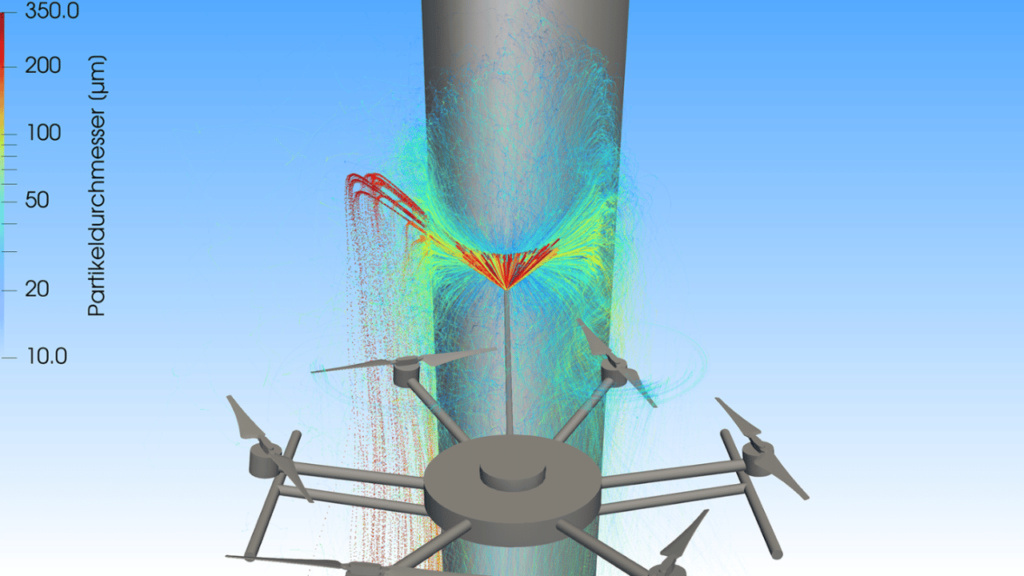

Dr. Oliver Tiedje, leading the effort at Fraunhofer IPA, highlights the technical challenges overcome. Fluid dynamic simulations were key in determining the right pressure and droplet size for the spray, ensuring that even under windy conditions, the application remains precise.

The potential of this technology extends beyond wind turbines. Think of overhead lines in rail transport or hard-to-reach areas in building refurbishment. The versatility of drones in coating applications is just beginning to be tapped.

As this technique moves towards series production, it’s not just about preventing ice. It’s about a sustainable, cost-effective approach to maintaining essential infrastructure. With backing from 19 companies and federal funding, the TURBO project is poised to change how we protect our wind turbines, all while keeping an eye on environmental impact and cost-efficiency.