Interestingly, solar panels stand as the quickest-booming electric-generating technology with equally exciting cost margins. Right until 2023. Solar will add more than twice as much new electricity generation globally compared to coal. A recent report suggests both solar and wind are growing. More rapidly than any other source of electricity generation technology in history.

Conservationists might love to see an upgrade in solar energy thanks to silicon. This semiconductor powers up to 95% of all solar panels worldwide. Nevertheless, manufacturing high-efficiency solar cells of over 25% requires pure silicon heated to over 900 degrees Celsius to remove defects. Considering its limited band gap capacity (the range of light it can absorb), this is a challenging issue to resolve.

While this might be true, perovskite (a calcium titanium oxide mineral) is much finer at absorbing light. Than crystalline silicon (solar cell material in panels) can even be ‘tuned’ to utilize portions of the solar spectrum. which silicon photovoltaics largely find difficult to attain. Perovskite also holds a strong preferable tolerance for defects and can function nicely with impurities and imperfections. However, researchers can easily and flexibly produce perovskites as well. In theory, solar panels made from this mineral could be much more affordable than their silicon competitors.

Solar cells have witnessed modification in recent years, ascending from a mere 3% in 2009 to above 25% recently. This broader scope in conservation has every interested person understanding it alike, raising enthusiasm among perovskites. However, a major stumbling block is that perovskite itself is rare to encounter. Artificial versions of perovskite have durability issues and vitality measured in months. Additionally, perovskite is rather delicate and prone to chemical and thermal damage.

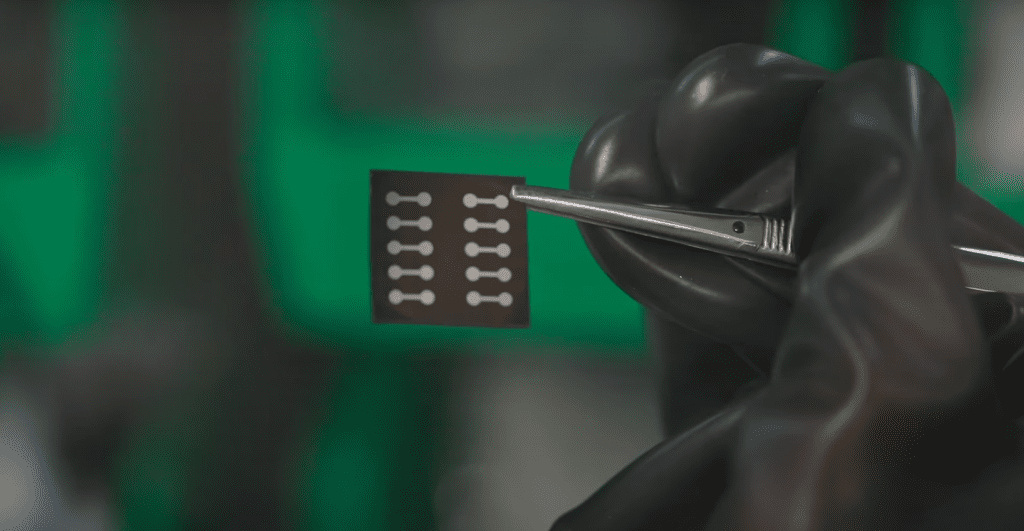

Despite breakthroughs, Rice University could alter the game in favor of perovskite to capsize silicon’s dominance in the solar sector. Furthermore, the newest research reveals a new synthetic crystal known as formamidinium lead iodide (FAPbI3) used in top-quality solar cells. These crystals are very stable and make strong solar panel photovoltaic films. Despite running for more than 1,000 hours at an unacceptable 85 °C, to enumerate, they only lost 3% efficiency. For this reason, formamidinium lead iodide (FAPbI3) usually degrades at this temperature.

“Right now, we consider that this is state of the art in terms of stability,” expressed Rice engineer Aditya Mohite, who has years of knowledge under his belt. “Perovskite solar cells have the potential to revolutionize energy production, but achieving long-duration stability has been a significant challenge.” The main trait of the study is the FAPbI3 precursor solution with specially designed two-dimensional (2D) perovskites. Certain types of perovskites help the growth of larger perovskites and make their structure stronger. Researchers uncovered that FAPbI3, while stable in chemicals, is not structurally robust. By using these special perovskites as guides, they make the FAPbI3 film work better and last longer. Adding the right kind of 2D crystals helped form high-quality FAPbI3 crystals that were more orderly inside and absorbed light extensively.

Solar cells made using these 2D templates performed better than other types. They stayed stable even after generating electricity from sunlight for 20 days. Adding a defensive layer makes them even more stable. which is a step towards creating perovskite solar cells ready for commercial usage. This advancement could change how solar power has the potential to make it cheaper and allow for lighter, more bendable solar panels. Unlike solar cells made of silicon, perovskite films form at lower temperatures, making it possible to produce them on plastic or flexible materials, which will also cut costs. “It should be much cheaper and less energy-intensive to make high-quality perovskite solar panels compared to high-quality silicon panels because the processing is so much easier,” said Isaac Metcalf, a Rice Materials Science and Nanoengineering graduate student and a lead author on the study.

“If solar electricity doesn’t happen, none of the other processes that rely on green electrons from the grid, such as thermochemical or electrochemical processes for chemical manufacturing, will happen,” Mohite said. “Photovoltaics are critical.” The need to meet the 2030 target for greenhouse gas emissions highlights the urgency of transitioning to solar energy. Preventing a 1.5-degree Celsius rise in global temperatures, which is a result of pollution,. Advancements in solar energy technologies and infrastructure are critical to achieving these goals. Consequently, several institutions supported the research, including the U.S. Department of Energy, the Hertz Foundation, the National Science Foundation, and the Air Force Research Laboratory.

Similar Posts

Rice University researchers, led by Aditya Mohite and Isaac Metcalf, have made significant progress in perovskite solar cell stability, bringing them nearer to market-ready standards. The researchers effectively created stability for the efficiency of formamidinium lead iodide (FAPbI3) solar cells by using an essential precursor solution with specially designed two-dimensional perovskites. To illustrate, the process results in solar cells that degrade less than 3% over 1,000 hours of operation at high temperatures. The results of the study are mind-boggling, as they bring the possibility of a greener future much closer to energy production, making solar panels lighter, more flexible, and cheaper to manufacture than silicon-based alternatives.