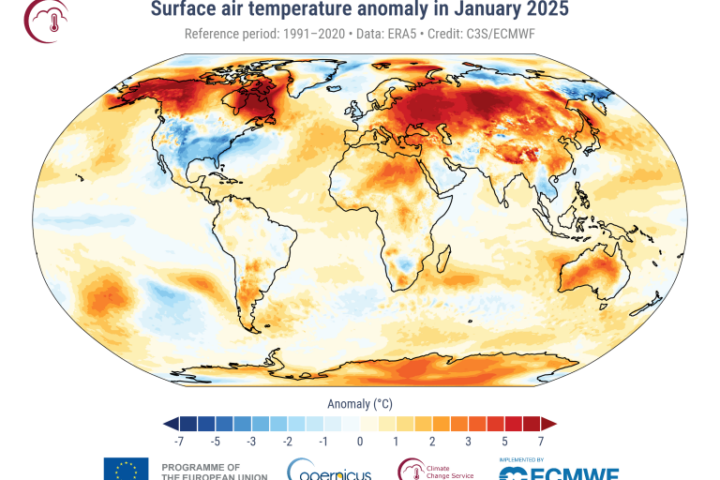

Addressing the challenge of decarbonizing stubborn industrial emitters, MIT scientists are pioneering carbon capture technologies. Industries like steel, cement, and chemical manufacturing, owing to the inherent use of carbon and fossil fuels in their production processes, are particularly hard to decarbonize. Current experimental technologies capture and convert carbon dioxide in two distinct steps, each demanding significant energy. The aim of the MIT research team is to merge these two steps into a singular, more energy-efficient system. Capturing and converting carbon dioxide from concentrated industrial sources, this integrated system could potentially operate on renewable energy.

The study, published in ACS Catalysts, unveils the intricacies of a single electrochemical process that captures and converts CO2 (carbon dioxide). An electrode is employed in the process to attract CO2 released from a sorbent, transforming it into a reusable form. While similar demonstrations exist, the mechanisms propelling the electrochemical reaction have remained ambiguous. The MIT team conducted thorough experiments to identify the primary driver of this reaction. Their findings highlighted the significance of the partial pressure of CO2. In essence, the purer the CO2 that interacts with the electrode, the more efficiently it can be captured and converted. This newfound understanding can guide scientists in refining similar electrochemical systems for optimal performance.

The results suggest that these systems might not be effective for dilute environments, such as capturing emissions directly from the atmosphere. However, they are ideal for capturing emissions from industrial processes, especially those without clear renewable alternatives. “It is essential to switch to renewables for electricity, but deeply decarbonizing industries like cement or steel is a complex affair,” according to study author Betar Gallant from MIT. Gallant emphasizes the need for interim solutions to manage emissions from these industries before they can be fully decarbonized. The co-authors of the study include postdoctoral researcher Graham Leverick, graduate student Elizabeth Bernhardt, and collaborators from Sunway University in Malaysia.

Traditionally, carbon capture technologies target emissions from power plants and manufacturing facilities. These technologies use large retrofits to channel emissions into chambers filled with a capture solution. This solution, a mix of amines, chemically binds with CO2, creating a stable form that can be separated from other gases. High temperatures, often generated from fossil fuels, are applied to release the captured CO2. Once purified, the gas can be stored, mineralized, or further processed into chemicals or fuels. Gallant notes the maturity of carbon capture technology but highlights its limitations, including its size, cost, and energy consumption.

Similar Posts

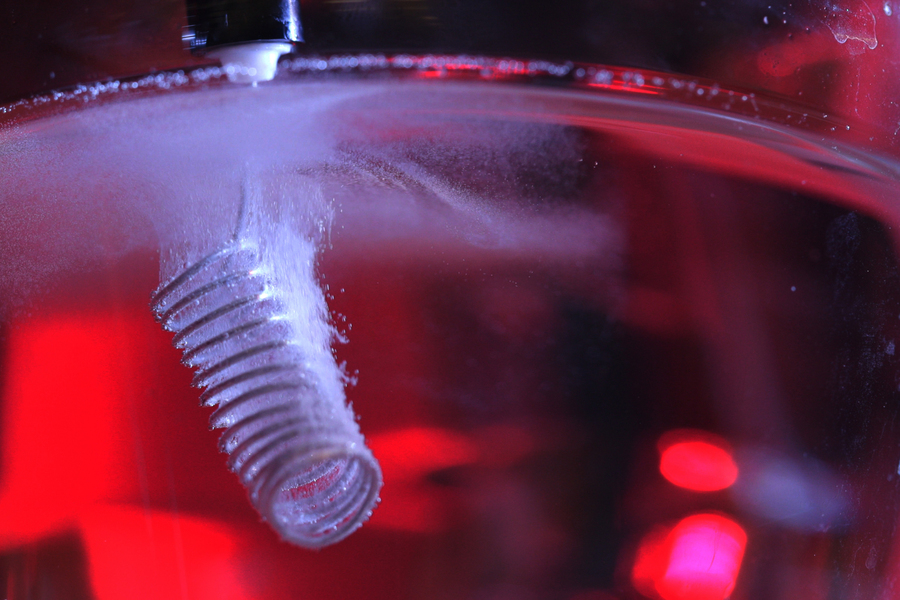

The innovation of the MIT group is an electrochemical system that recovers and repurposes the captured CO2. This system could potentially be powered entirely by renewable electricity. An electrode designed to fit into existing carbon-capture chambers is the core of their concept. When voltage is applied, electrons flow onto the reactive form of CO2, converting it using protons from water. This process makes the sorbent available to bind more CO2, eliminating the need for steam. The team of Gallant previously showcased this electrochemical process’s ability to capture and convert CO2 into solid carbonate.

The new study delves deeper, examining the specific reactions that drive this electrochemical process. The experiments of the team revealed that the concentration of free-floating CO2 molecules in the solution was the most influential factor. The amount of carbon monoxide produced at the end of the reaction was determined by this “solo-CO2.” Leverick explains, “It is easier to react with this ‘solo-CO2’ than with CO2 captured by the amine.” This insight suggests that the process could be feasible for industrial streams with high CO2 concentrations.

Gallant clarifies that their method is not a removal technology, but a recycling solution. The system allows CO2 to be recycled multiple times, supporting existing industrial processes with reduced emissions. Gallant envisions a future where electrochemical systems facilitate permanent CO2 storage, a true removal technology. Support for the research was received from Sunway University in Malaysia.

Electrochemical reactive capture of CO2 is gaining traction as a means to achieve net-zero and eventually negative greenhouse gas emissions. The integration of capture and conversion introduces complexity due to the potential reactants, especially in aqueous-based solutions. The study underscores the importance of understanding amine-based sorbents’ influence on CO2 reduction mechanisms. Emphasizing the role of dissolved CO2 as the active species in amine-mediated CO2 conversion, the research paves the way for improving these processes.