Recently, situated in East China, Dalian University of Technology (DUT) professors made a breakthrough in the research of advanced, wide-temperature, high-safety composite quasi-solid-state electrolytes. Professor Dong Xufeng and Professor Huang Hao both from the School of Materials Science and Engineering at DUT presented their research with the aim of improving the safety standards of lithium battery technology. Their study, titled “Application of advanced Wide-Temperature range and flame retardant “Leaf-Vein” Structured functionality composite Quasi-Solid-State electrolyte,” has been published in the well known journal in the field of energy materials, Energy Storage Materials.

The stability and safety of lithium batteries in extreme environments are critical issues that need attention. Traditional liquid electrolytes, used in batteries, often have problems like catching fire, leaking, and not working well in very hot or cold temperatures. These issues can slow down the development of battery storage technologies. Quasi-solid-state electrolytes (QSEs) are a new type of material being developed to solve these problems and improve battery safety and performance. Hydrogel electrolytes, with their excellent ionic conductivity, flexibility, functionality, low cost, and environmental compatibility, are ideal QSE materials. However, hydrogel electrolytes still face challenges such as a narrow electrochemical window, lower mechanical strength, and susceptibility to freezing.

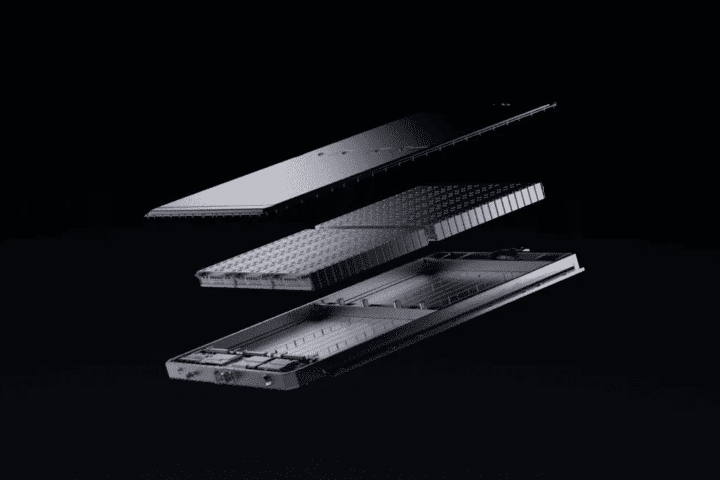

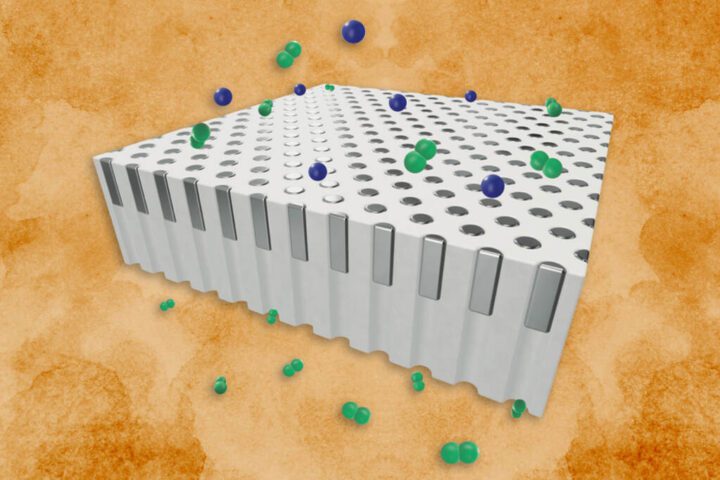

The paper demonstrates an innovative design and preparation of a new type of quasi-solid-state gel electrolyte with a “leaf vein and flesh” structure, inspired by natural materials—leaves. Electrospun nanofiber networks act as “leaf veins,” providing robust support and puncture resistance; a UV-curing technique is used to in situ generate a CG-PAM dual-component gel coating on the outer layer of the nanofibers, forming the “leaf flesh” structure. The resulting QSE exhibits stable electrochemical performance and is endowed with unique functionalities, especially in terms of flame retardancy and anti-freezing properties, which are significantly enhanced.

Similar Posts

This QSE material demonstrates excellent flame retardancy (non-flammable for 30 minutes), a wide electrochemical window (4.2 V), high tensile strength (0.25 MPa), excellent anti-freezing properties (down to -60°C), and stable electrochemical performance (capacity retention of 75% after 500 charge-discharge cycles). The outstanding performance of this material highlights the innovative designs and variety of materials used in making it. This ensures that batteries made with it can be safely used in extreme conditions, like in outer space or the polar regions.

The “leaf vein” structured quasi-solid-state electrolyte offers excellent flame retardancy, low-temperature anti-freezing properties, and electrochemical stability for application in the energy storage field.