Across the world, researchers are bringing new studies to reduce the burden on climate challenges. Researchers from Cambridge University have successfully developed a new process that produces zero-emissions cement by recycling cement. This method was published in the journal Nature on 22 May. Named an absolute miracle by one of the scientists, this innovation uses electrically-powered arc furnaces.

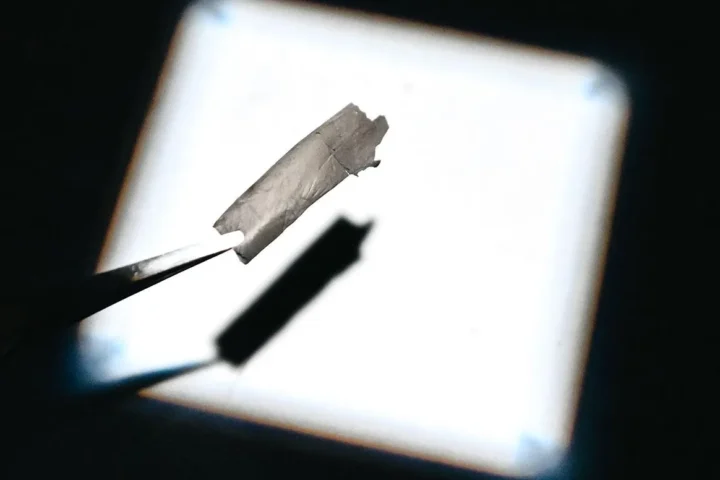

The first author, Dr. Cyrille Dunant from the Cambridge Department of Engineering, explained that he had a vague idea from previous work: if it were possible to crush old concrete, taking out the sand and stones, and then heating the cement to remove the water, it would form clinker again. He added, “a bath of liquid metal would help this chemical reaction along, and an electric arc furnace, used to recycle steel, felt like a strong possibility. We had to try.”

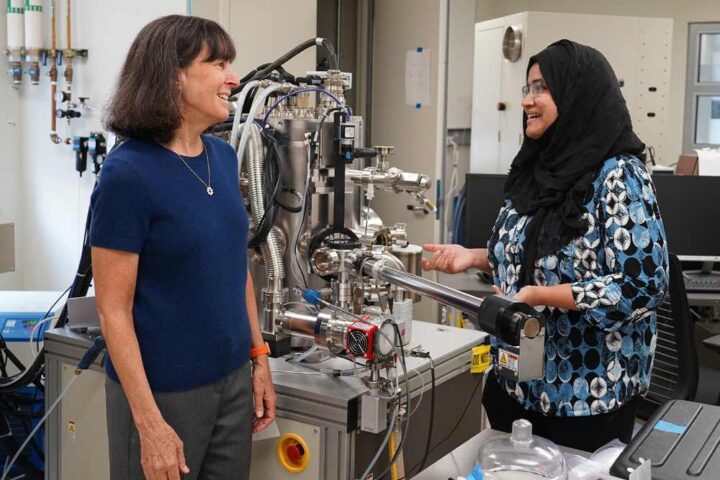

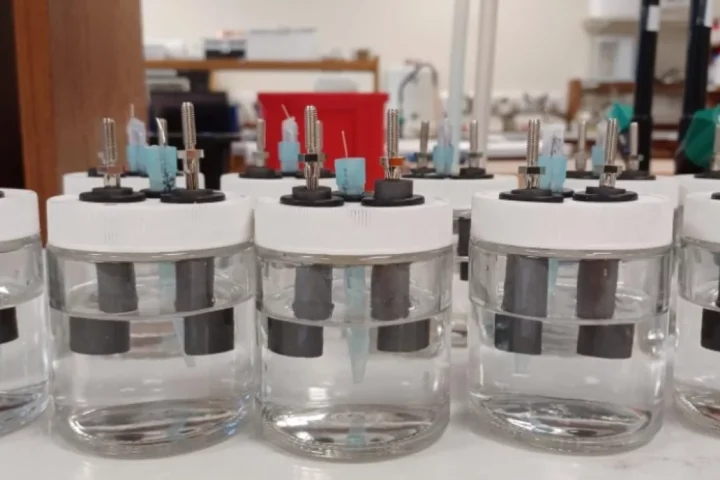

The clinkering process requires heat and the right combination of oxides, all of which are in used cement but need to be reactivated. The researcher conducted tests for a range of slags made from demolition waste and added lime, alumina, and silica. These slags were processed in the Materials Processing Institute’s EAF with molten steel and rapidly cooled.

Concrete is the second-most-used material on the planet, after water. The electrically-powered arc furnaces are used simultaneously for steel recycling as well as cement recycling, the carbon-hungry component of concrete. Moreover, it is responsible for approximately 7.5% of total anthropogenic CO2 emissions. This offers a scalable, cost-effective way to reduce concrete emissions to meet global demand and address the world’s biggest decarbonization challenges.

Researchers suggest that used cement is an effective substitute for lime flux, which is used in steel recycling to remove impurities and ends up as the waste product known as slag. By replacing lime with used cement, the end product, recycled cement, can be used to develop new concrete. Recently, tests carried out by the Materials Processing Institute, a partner in the project, showed that recycled cement can be produced at scale in an electric arc furnace (EAF).

This method does not add cost-effectiveness to concrete or steel production and reduces the emissions from both, due to the reduced need for lime flux. If the EAF is connected to or powered by renewable energy, the method could produce zero-emissions cement.

Similar Posts

“Producing zero emissions cement is an absolute miracle, but we’ve also got to reduce the amount of cement and concrete we use,” explained Professor Julian Allwood from Cambridge’s Department of Engineering. “Concrete is cheap, strong and can be made almost anywhere, but we just use far too much of it. We could dramatically reduce the amount of concrete we use without any reduction in safety, but there needs to be political will to make that happen.”

The Cambridge Electric Cement process is scaling rapidly, with researchers saying they could be producing one billion tonnes per year by 2050. This represents roughly a quarter of current annual cement production. The researchers have filed a patent on the process to support its commercialization. The research is supported in part by Innovate UK and the Engineering and Physical Sciences Research Council.