Together with DeepDrive, BMW is working on a revolutionary electric motor technAology that promises greater power, higher efficiency, and autonomy. It features revolutionary dual-rotor technology. After the necessary bench tests, the brand is ready to equip them in cars and move on to the road testing stage. A new propulsion unit will also be installed in BMW Group models.

Manufacturers are investing large amounts of funds into their research and development programs to obtain the latest technologies, allowing them to stand out in the competition. This adds value to their products and the new models that reach the market. For example, Mercedes-Benz acquired YASA, a British firm that has specialised axial flux motor technology that can elevate electric vehicle engines to new standards.

BMW did not want to fall behind its star competitor’s move, leading the Munich-based brand to work on a motor that would allow them to offer “super-efficient” cars. Sports Coupe, another German brand, has been working on the same technology for some time.

A Major Surprise: BMW’s Innovative Electric Motors

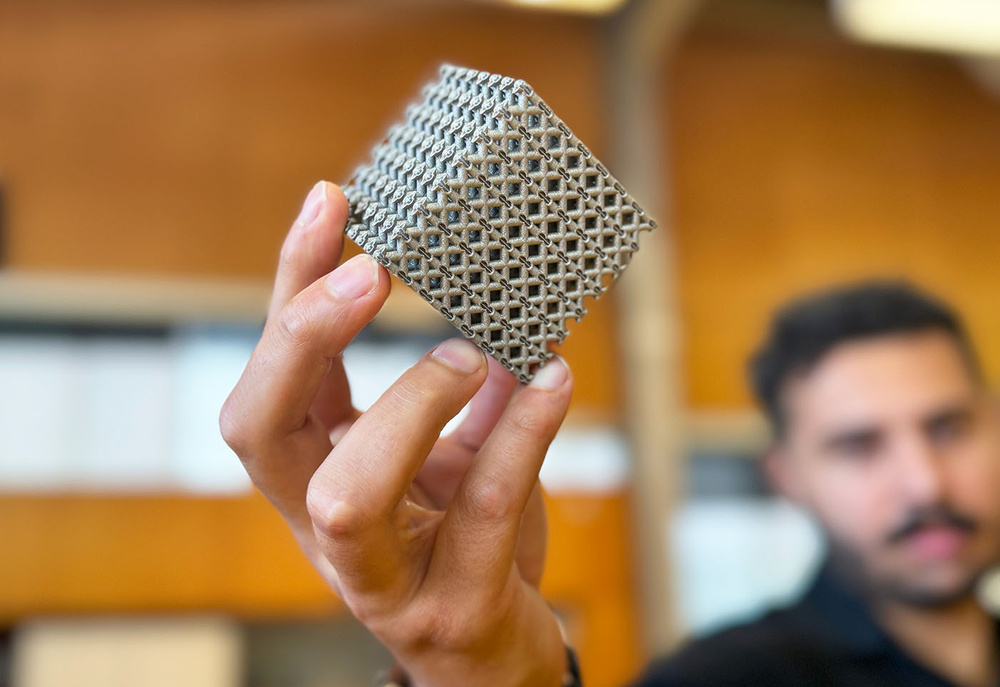

To achieve these ultra-efficient electric motors, BMW has teamed up with DeepDrive. BMW has confirmed that DeepDrive has merged two electric motors into a single unit, creating a compact motor that is energy-efficient and has a high torque density. According to the German manufacturer, in a conventional electric motor, the stator moves an internal or external rotor, while DeepDrive’s stator drives both rotors simultaneously.

The new electric motor from BMW and DeepDrive allows for an all-wheel-drive system, where each wheel hub has its own electric motor. The technology can also be used in a traditional centralised drive system, where a central motor block drives the vehicle. These motors will require less space and be more energy-efficient, lighter, and less costly, making them a viable option for a wide range of vehicles.

DeepDrive and BMW’s Ongoing Partnership

“Collaborating with BMW gave us a springboard really early on,” says Felix Pörnbacher, co-founder of DeepDrive. “It helped us navigate the complex corporate world and meet and exceed the rigorous standards of the automotive industry. Our goal now is to integrate it into a production model,” he adds.

Similar Posts

BMW began its relationship with DeepDrive in 2021, intensifying their collaboration since the International Automobil Ausstellung (IAA) in Munich that same year. The company also works with other manufacturers and suppliers, such as Continental. In 2024, the motor prototype was awarded the German Innovation Award.

This major innovation could prove to be one of the most promising in recent times, representing a significant advance in the sustainable mobility industry and a step towards a world where people choose sustainable and efficient mobility that significantly contributes to environmental protection.