The world has been confronted with the challenges of climate change, particularly the need to reduce fossil fuel use to achieve climate goals. Researchers from North Carolina State University have discovered a solution to replace synthetic, petroleum-based plastic films with biopolymer obtained from the ocean. This significant research was published in the Cell Report Physical Science on December 11, 2023.

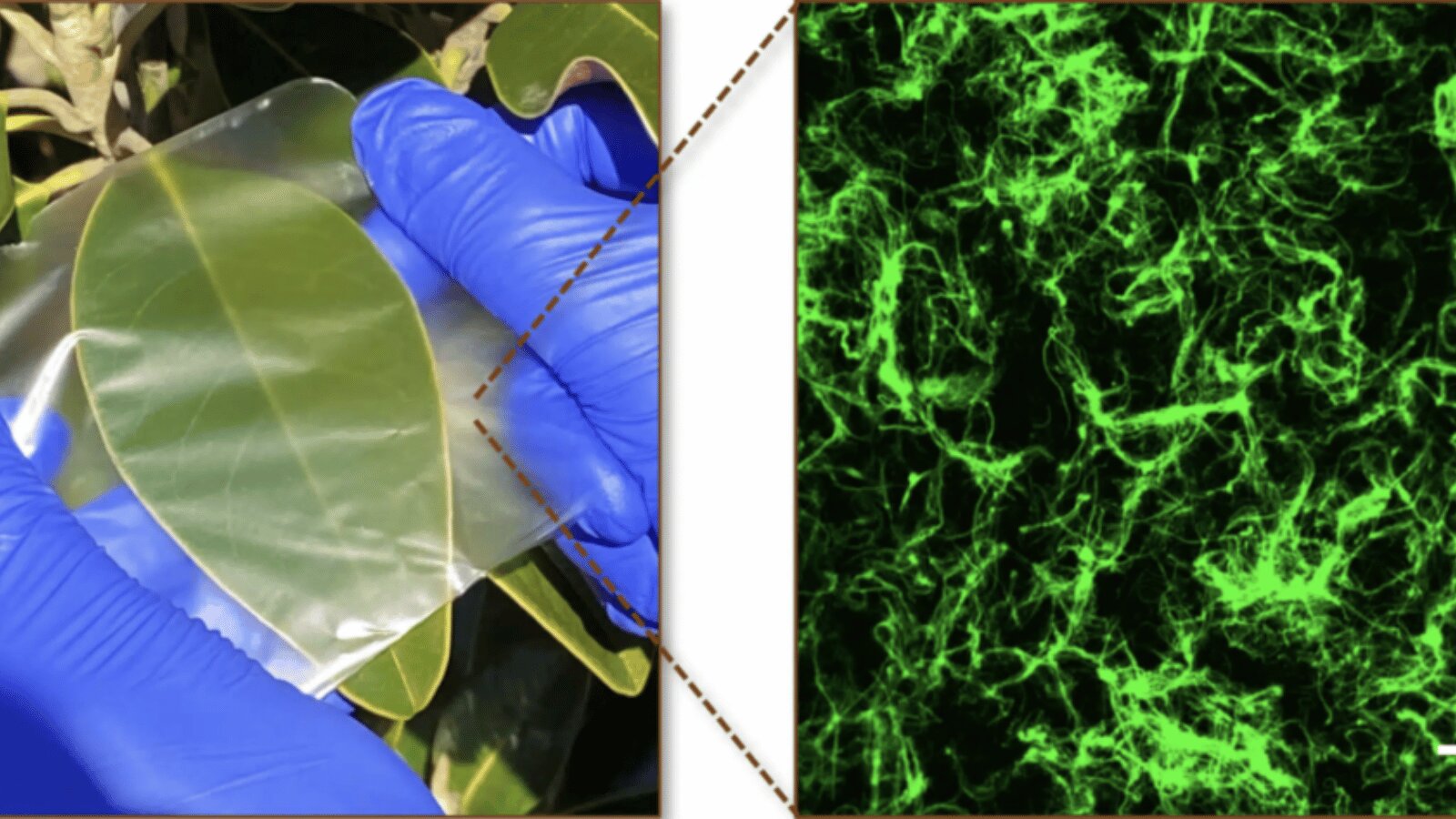

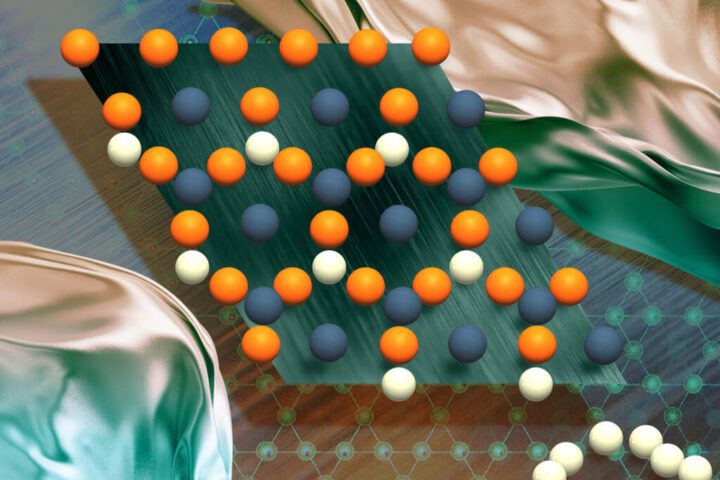

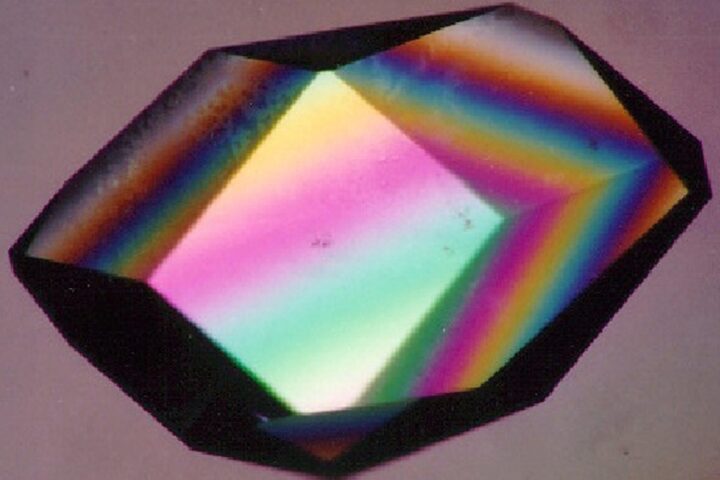

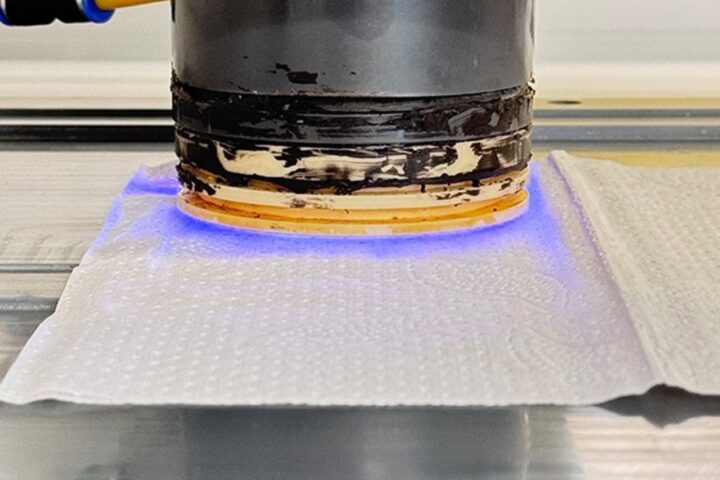

The researchers combined chitosan, a biopolymer that makes crab shells hard, with agarose, a biopolymer extracted from seaweed used to make gels. This combination created unique biopolymer composite films with enhanced strength. These films are biodegradable, possess antibacterial properties, repel water, and are transparent. Such findings could eventually lead to sustainable packaging films for food and consumer goods.

The results indicate the sustainability of AG-CS SDC films for biodegradation in the soil environment. This process likely involves enzymatic hydrolysis and microbial degradation. Notably, these films combine two formerly conflicting features: antibacterial activity and biodegradability.

Dr. Orlin Velev, S. Frank and Doris Culberson Distinguished Professor of Chemical and Biomolecular Engineering at NC State and the corresponding author of the paper, raises future queries. He asks, “How do we find sustainable replacements for synthetic polymers?” He points out that while synthetic polymers make very good films, the goal is to replace them with natural biopolymers. The challenge lies in adjusting the joint structure of these natural polymers, such as agarose and chitosan, to retain the desirable properties of synthetic polymers in a sustainable, biodegradable film.

Similar Posts

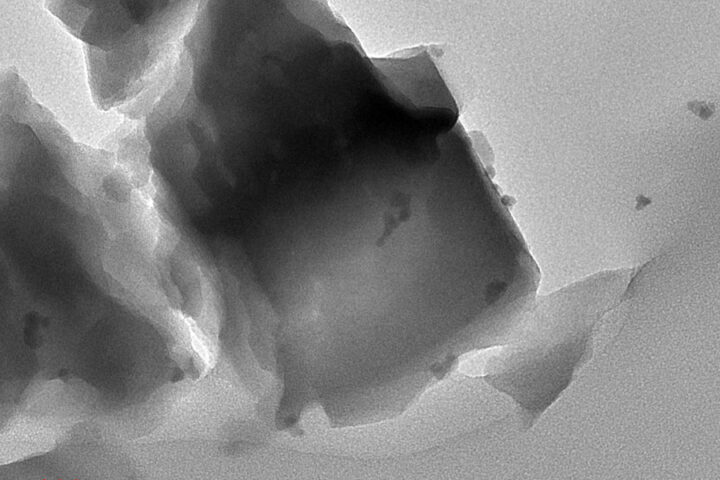

Yosra Kotb, an NC State Ph.D. graduate and first author of the paper, explains the challenge of modifying natural polymers chemically. However, altering their morphology to use them as composites is possible. The team uses chitosan dendritic particles to reinforce the agarose matrix, enhancing the mechanical properties due to the compatibility of both materials. When mixed, the opposite charges of chitosan and agarose neutralize, making the resulting material more resistant to water.

Velev added that while the composite is initially strongly antibacterial, it is still susceptible to bacterial colonization over time. Therefore, after a month underground, it would biodegrade readily. He also mentioned that his lab would continue working on improving the structure of the biopolymer composite films, aiming to match the properties of synthetic polymer ones.

In response to Karmactive’s inquiry on implementing new technologies for climate change mitigation, Dr. Orlin highlighted a strategic plan. He stated, “The future development requires the introduction of techniques where the new polymer substitutes will be produced to scale. Such scale-up techniques could include, for example, continuous processes similar to paper-making, which in turn should also be safe for the environment and low-energy consumption.” Dr. Orlin’s vision involves scaling up environmentally friendly polymer substitutes with methods that prioritize energy efficiency and ecological safety, drawing parallels to the well-established processes in paper manufacturing.

This research, supported by the National Science Foundation, has significant implications. World leaders have already discussed at Cop28 how to address climate issues that are increasingly posing dangers to humankind and other living things.