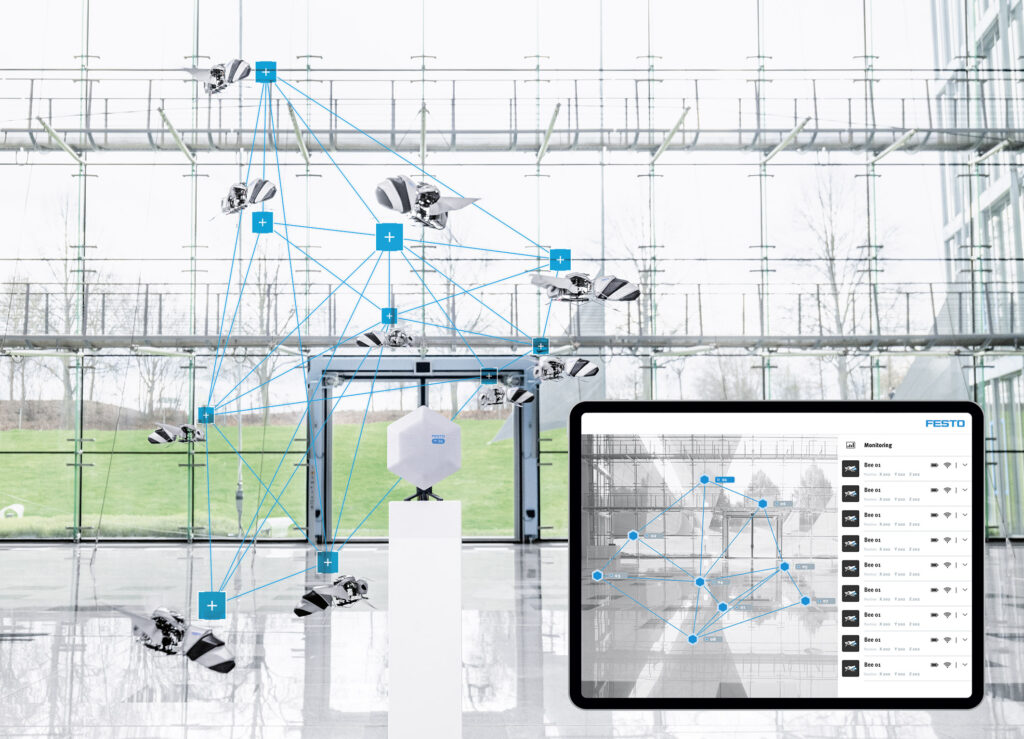

German company Festo recently released a press release announcing its BionicBee biomimetic bee, which, compared to traditional multi-rotor drones, uses a flapping-wing flight scheme (wings flapping back and forth 180 degrees to provide lift) and claims to have achieved “fully autonomous flight.” The Esslingen-based company prsentred it at the Hannover Messe.

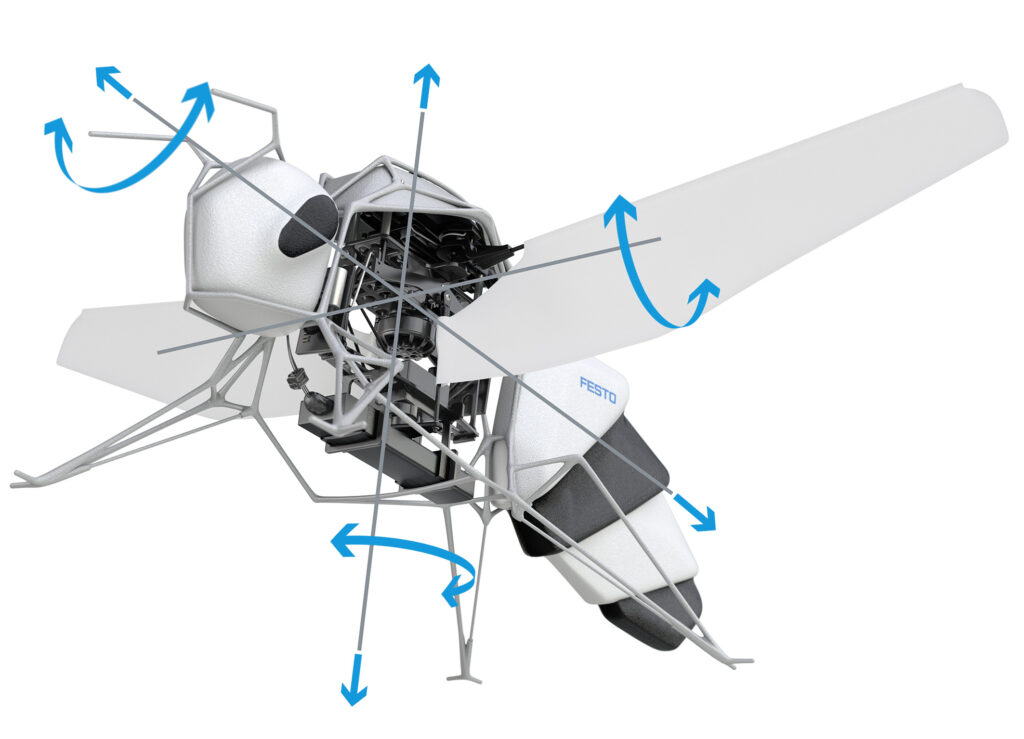

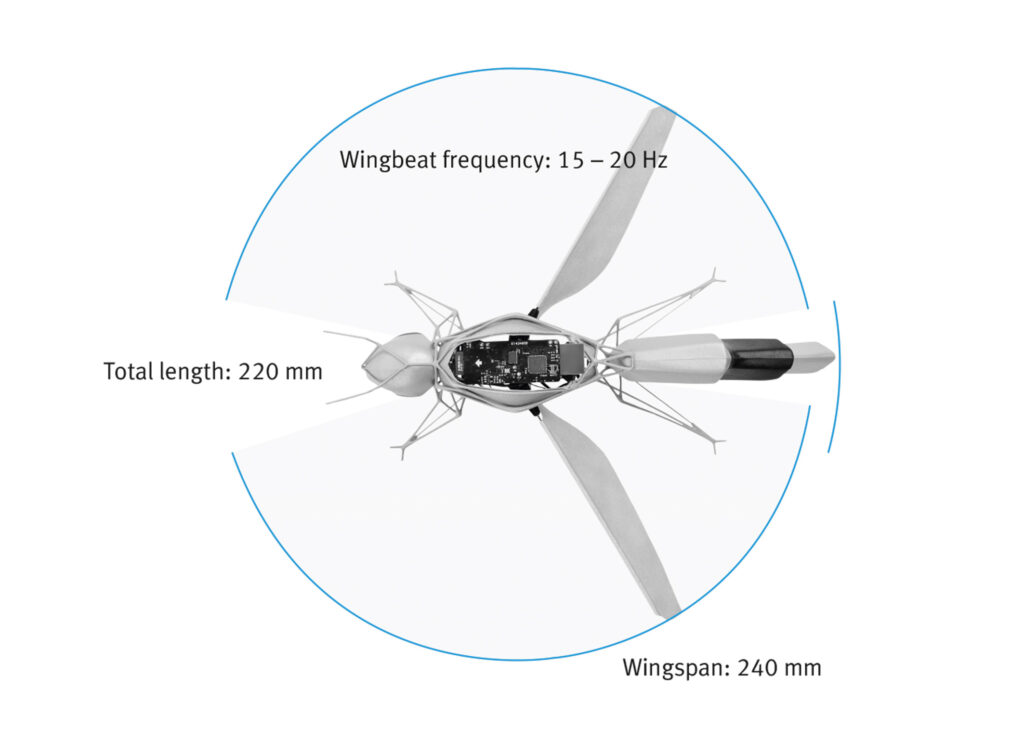

The BionicBee is 22 centimeters long and has a wingspan of 24 centimeters, weighing only about 34 grams. It is said to be the “world’s smallest biomimetic flyer” to date. A brushless motor drives the wings, which beat at a frequency of about 15 to 20 hertz. Three servo motors change their geometry. Lift is varied by the wing position. In addition, a battery and communication technology are built into the body.

There is an indoor localization system that works with Ultra Wideband (UWB) technology. It consists of eight UWB anchors installed on two levels in the room. These allow for precise time-of-flight measurement, enabling the bee to locate itself in space. Since the BionicBees fly in swarms, the UWB anchors send signals to the individual bees, which independently measure the distances to the respective transmission elements and calculate their own position in space based on timestamps. For flight in a swarm, a central computer specifies paths for the bees to follow.

In designing the BionicBee, Festo used generative design methods for the first time: A software is fed with some parameters. Based on defined design principles, it then finds the optimal structure for a stable construction with minimal material usage. The robots were then manufactured by hand. Since even the slightest manufacturing differences can affect flight behavior, the bees have an automatic calibration function: After a short test flight, each bee determines its individually optimized controller parameters. Intelligent algorithms then correct the hardware differences, allowing the entire swarm to be controlled from the outside as if all bees were the same.

Similar Posts

The robot bee was developed as part of the Bionic Learning Network, a research initiative involving Festo as well as other companies and several German and foreign research institutions. The goal of the cooperation is to transfer methods or mechanisms from nature to technical systems. Over the years, various grippers inspired by animals have been developed, such as the Octopus Gripper, which grasps an object like a tentacle, or the Flex Shape Gripper, modeled after a chameleon’s tongue. The Bionic Learning Network has been focusing on the topic of flight for over 15 years, developing a flying seagull or a robotic dragonfly, for example. The BionicBee is the smallest of the flying robots developed in the Bionic Learning Network.