Direct Air Capture technology, initially designed by Airbus and the European Space Agency (ESA) to purify air aboard the International Space Station (ISS), is now being adapted for terrestrial applications aimed at mitigating climate change. The innovative ecosystem at Airbus is actively exploring the potential of internal innovations like DAC for applications beyond aviation, contributing to a circular economy. Airbus Scale, the innovation acceleration unit, is delving into how DAC can be scaled and applied to industries with significant CO2 production or consumption after proving its efficacy in space and on submarines.

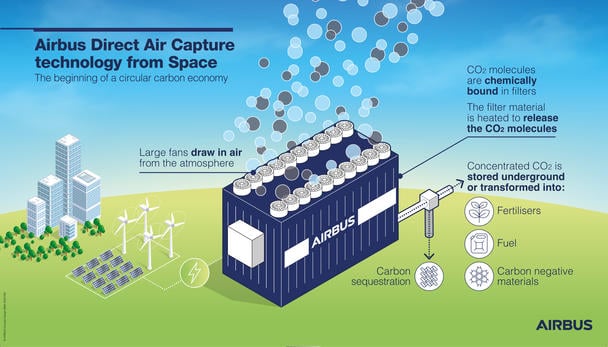

DAC technology offers a sustainable alternative to traditional CO2 production methods, which often involve polluting combustion and extensive transportation, thereby exacerbating emissions. By capturing and supplying CO2 directly onsite, DAC eliminates the need for external suppliers, reducing costs and carbon emissions for industries. The technology employs a solid amine-based filter to capture CO2 from the air, which is then heated to release the gas, resulting in two streams: oxygenated air and pure CO2. On the ISS, the oxygenated stream is vented back into the space station for the astronauts to breathe, highlighting the practicality of DAC in varied environments.

DAC’s adaptability allows for a continuous onsite source of CO2, recycled directly from the atmosphere, presenting a myriad of possibilities for industries. Particularly, farmers in vertical and greenhouse farming can leverage DAC to become self-sufficient in CO2 supply, avoiding logistical hassles and benefiting from stable prices and a smaller carbon footprint. The technology is particularly promising for the production of e-fuels, synthesized by combining atmospheric CO2 with hydrogen from sustainable energy sources, offering a carbon-neutral solution. DAC can significantly contribute to the power-to-liquids (PtL) processes, essential for making e-fuels, and help neutralize emissions in the aviation industry, where sustainable aviation fuels are already reducing CO2 emissions by 80%.

Similar Posts

Another intriguing application of DAC is in carbon sequestration, meeting the increasing demand for capturing and storing CO2 to prevent it from entering the atmosphere. The liquid CO2, obtained from DAC, can be safely injected into saline formations for underground storage. Airbus is committed not only to minimizing the environmental impact of its products and services but also to aiding other industries in achieving sustainability through technologies like DAC.

On 13 September 2023, a team from Airbus comprising two engineers and a developer, Antje Bulmann, Viktor Fetter, and Tobias Horn, was shortlisted for the prestigious German Future Prize (Deutscher Zukunftspreis) 2023 for their work on DAC technology. Awarded by the German Federal President, the Prize recognizes scientific excellence and application that yields societal benefits. Airbus Chief Technical Officer, Dr. Sabine Klauke, commended, “The trio’s achievement in producing the DAC modules is a perfect example of how technologies from the space industry can be refined for use on Earth and help to reduce CO2 emissions.”

The DAC modules developed by the Airbus team are adaptations of adsorber technology used on the ISS to remove CO2 exhaled by astronauts. Now operational on Earth, these modules employ an absorptive DAC process to extract CO2 from the air. Airbus collaborated on developing an amine resin that efficiently captures CO2 even at low concentrations, marking a significant advancement in the technology. The process involves drawing in air through a fan, which then flows over a solid amine filter, selectively binding the CO2 and releasing air with negligible CO2 content. Once the resin is saturated with CO2, the filter is heated, regenerated, and a concentrated stream of CO2 is desorbed for repurposing or sequestration.

Concurrently, Airbus is working on a plethora of technologies, including fleet modernization, efficient air traffic management, Sustainable Aviation Fuels (SAF), DAC, and hydrogen, to curb CO2 emissions in aviation. The versatility of DAC technology opens up avenues for its application in various industries, including agriculture and e-fuels production, showcasing its potential in addressing critical environmental issues. The development of customizable hardware units by Airbus allows for the tailoring of DAC technology to meet the specific needs of different customers and industries.

The integration of DAC in vertical farms exemplifies environmental improvement, as it not only lowers emissions through reduced land use but also enhances plant growth by boosting photosynthesis with captured CO2. The emergence of DAC as a viable solution for carbon capture and storage underscores its potential in addressing the growing demand for carbon sequestration across industries. The potential of DAC in accelerating the production of e-fuels is noteworthy, as it plays a pivotal role in synthesizing carbon-neutral solutions that are integral to the energy transition.

The commitment of Airbus to sustainability is evident in their ecosystem-based approach, which seeks to find new uses for aerospace technology in diverse industries. The recognition of the Airbus team’s work on DAC by the German Future Prize highlights the significance of adapting space technologies for terrestrial environmental solutions. Dr. Sabine Klauke’s commendation of the team’s achievement emphasizes the practicality and potential of DAC in reducing CO2 emissions on Earth. A technological breakthrough in the field of carbon capture is marked by the development of an efficient amine resin by Airbus, capable of capturing CO2 at low concentrations.

The dual-phase process of DAC, involving the selective binding of CO2 and its subsequent desorption, showcases the technology’s efficiency and adaptability. The dedication of Airbus to reducing the aviation industry’s carbon footprint is demonstrated by the multifaceted approach of Airbus in exploring various technologies, including DAC. The adaptability and customizability of DAC technology make it a promising solution for a range of industries, from agriculture to fuel production. The application of DAC in e-fuels production is a testament to its role in fostering carbon-neutral solutions and advancing the energy transition.

The initiative of Airbus to explore the terrestrial applications of aerospace technology like DAC reflects their commitment to contributing to a circular economy and environmental sustainability. The successful adaptation of DAC modules, originally designed for the ISS, exemplifies the potential of space technologies in addressing terrestrial environmental challenges. The shortlisting of the Airbus team for the German Future Prize 2023 marks a significant milestone in the journey of DAC technology from space to Earth, highlighting its potential in combating climate change.