Polybion bio is a space for revolutionary and forward thinkers who use cutting-edge technology modeled on nature’s design. Polybion creates premium, high-performance biomaterials from fruit waste. Founded by brothers Axel and Alexis Gómez Ortigoza with Bárbara González Rolón, Polybion was established by a diverse group of biotechnologists, chemists, biologists, engineers, financers, creatives, designers, and political scientists. The company is highly inspired by natural processes and organisms and shares a common dream to create a better world. Their locally-produced agro-industrial fruit waste is used as raw materials to formulate a sustainable leather alternative.

Polybion prioritizes our planet and produces superior materials at the same time. It manufactures the building blocks of life and circulates supply chains. Furthermore, natural systems are cyclical, and their waste becomes nutrients that initiate new growth. So, Polybion learned from nature and developed a production model that is not linear but a loop that simultaneously alleviates three major environmental problems- livestock, food waste, and plastic.

While Polybion thoroughly represents a paradigm shift from centuries of source-mining practices to the regenerative cultivation of resources. Their purpose is to grow a better future one cell at a time. Their produced cell Celium in which Cel, derived from the word- cellulose is the most abundant organic polymer on Earth, and ‘ium’ is the Latin suffix used in chemical elements.

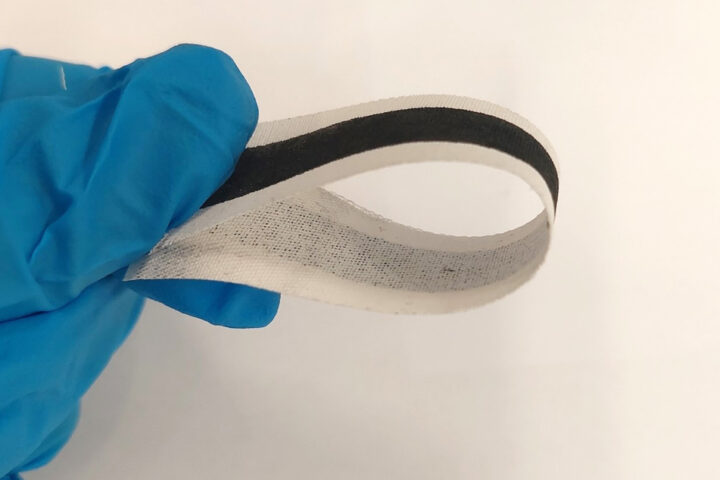

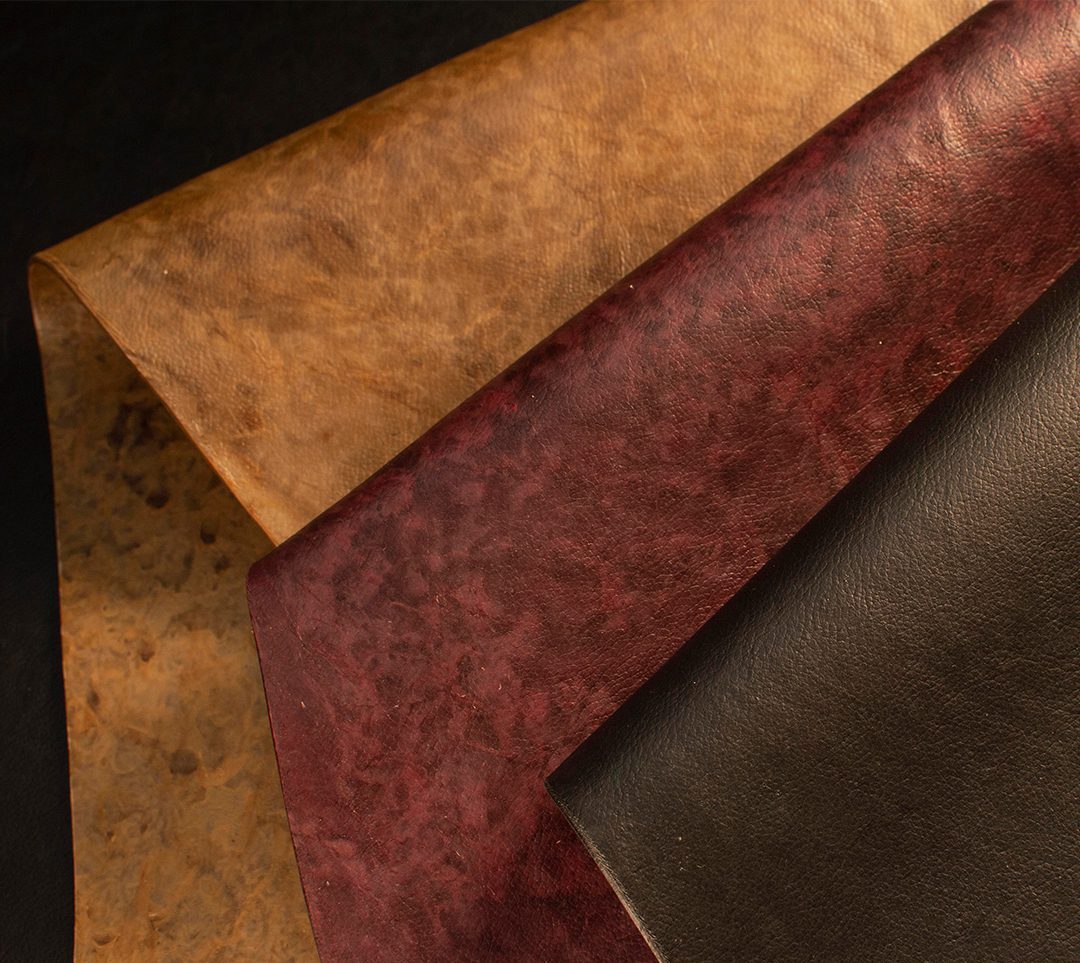

Celium is a common alternative that diminishes the use of animal-based leather and petroleum-derived synthetics mainly composed of bacterial cellulose. Celium is a versatile textile with endless design possibilities. The best part is that it can be customized by color, graining, embossing, and water resistance while preserving its strength.

Additionally, Celium is vegan and organic and weighs less than cowhide. The researchers at Polybion control the thickness through its growth, making it easier to tailor. Each Celium piece is unique and distinct, as a fingerprint lends as the hallmark of luxury. Polybion industrialized cellular agriculture to bio-fabricated celium. They combine its materials with bioengineering, and their technology is scalable, modular, and high yielding.

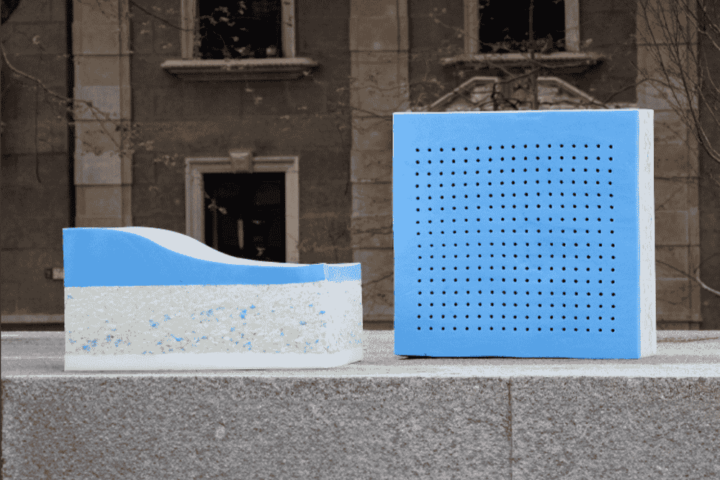

Polybion grows Celiium by feeding bacteria with agro-industrial fruit waste. The process starts with setting up the perfect environment for the cells to self-organize. They create the cellulose structure as a metabolic by-product. Then, once the Celium is formed, Celium’s cell-based membrane undergoes a sustainable stabilization process to achieve its high-performance characteristics. Fortunately, there is enough fruit waste to produce at least 168,000,000 sqft of Celium annually. And, as there are no hazardous chemicals released in any part of this unique process, the Celium is as circular as it gets.

For decades, humans have used leather, silk, wool, fur, down, and exotic fur. But, due to the present environmental and ethical challenges using animal skin has been a pressing problem for humans. Nonetheless, the advancements and invention of synthetics in the 20th century have allowed these inexpensive alternatives to exist.

Polybion uses biology to excavate unique solutions to de-intensify these unavoidable issues with the help of Celium. Lastly, Celium turns out to be an up-scaled alternative to animal leather and petroleum-based products.