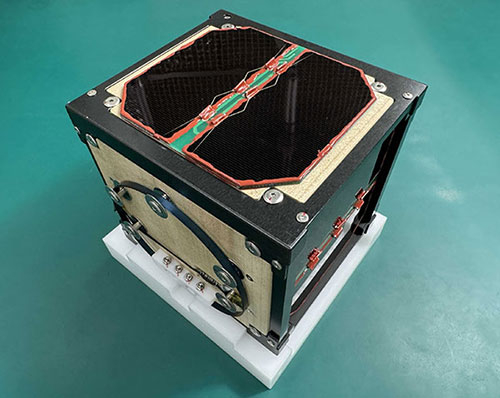

This century is full of recycling waste and adopting a circular economy. However, the ESA (European Space Agency) has gone a step further by innovatively realizing the possibility of a discarded orange peel becoming part of a satellite orbiting Earth. A team of researchers used various types of industrial waste to develop 100% bio-sourced materials. Part of the Discovery and Preparation elements of ESA’s Basic Activities and submitted via the OpenSpace Innovation Programme, this project supports a more sustainable space industry by using waste sources and a circular economy approach. Composites are key materials of modern life, used everywhere from sports equipment to dentistry and construction to airplanes.

\ESA has worked with Cote D’Azur University to develop a novel class of composites crafted entirely from bio-sourced materials derived from sustainable sources. The “100% Biobased Thermosets With High Performances For Structural Materials And Composites For Space Application” project was submitted through the OSIP channel and implemented through ESA Discovery and Preparation elements. The cooperation has taken the form of co-sponsored PhD and a post-Doctorate research.

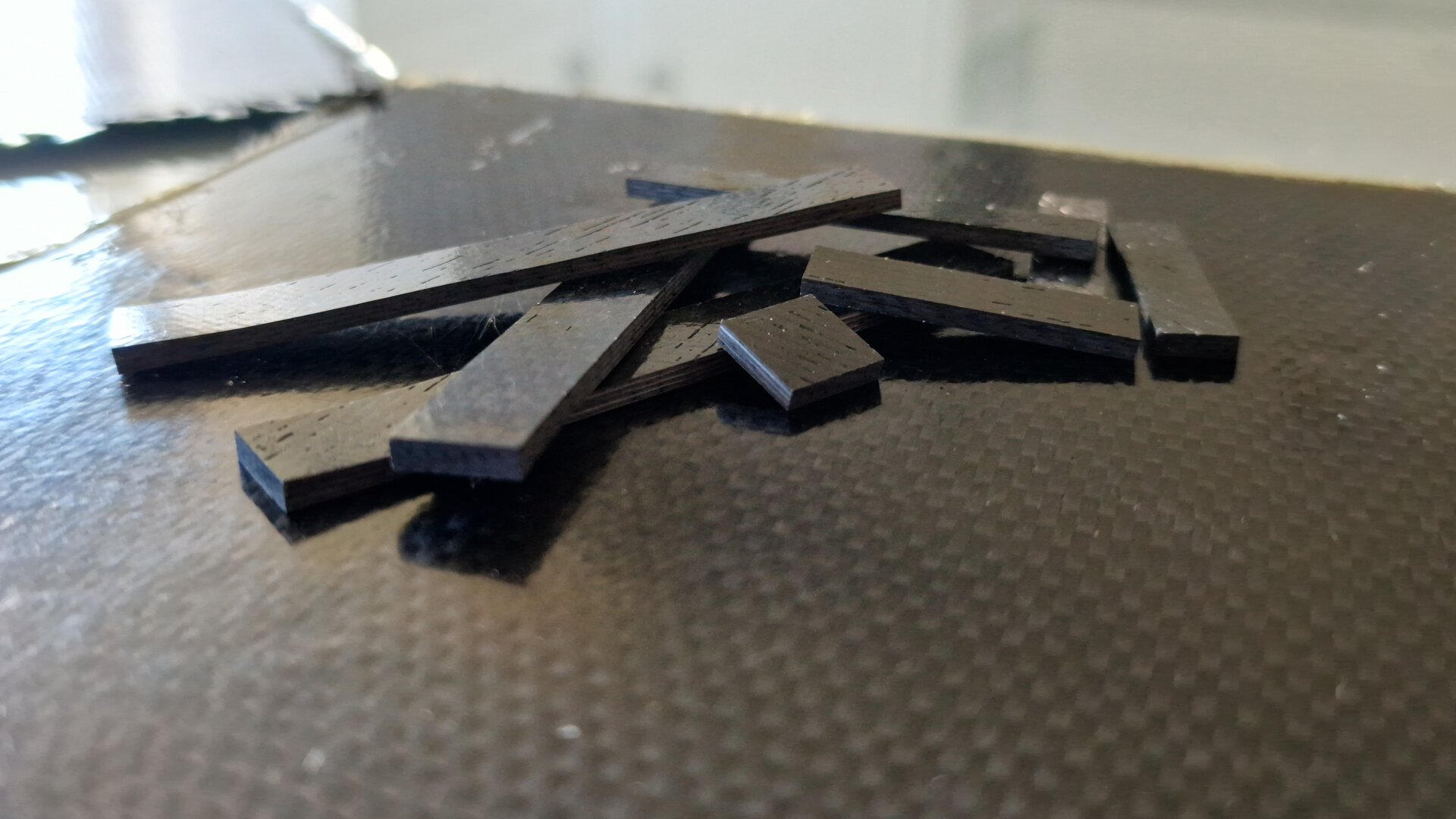

ESA materials engineer Ugo Lafont explains, “We didn’t want to grow new crops for this specific purpose, but we wanted to use what already exists in nature or what is already existing as waste.” Alice, a member of the team says, “We really pushed the boundaries of material science, developing innovative composites based on waste, which meet the requirements for space applications.” The space qualification tests have been conducted by using the project’s specialist facilities at ESA’s ESTEC technical Center in the Netherlands as well as Thales Alenia Space in Cannes.

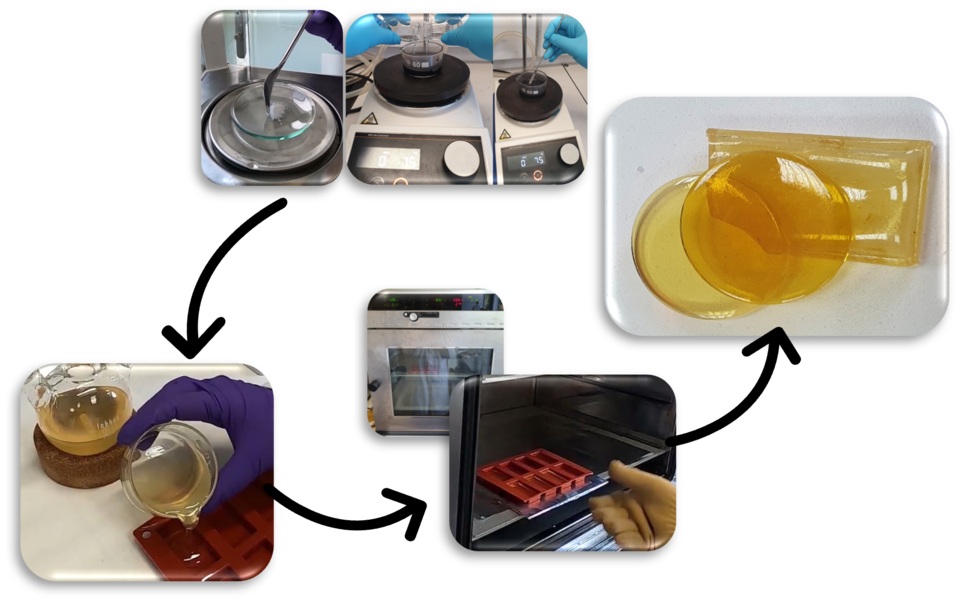

This innovative reality is being studied through a co-sponsored research activity, where a team of researchers used various types of industrial waste to develop 100% bio-sourced materials. Photo Credits: European Space Agency

The team is now implementing the project to scale up the production to make commercial applications possible. The team has used the so-called 3Rs – reuse, recycle, and repair in making a 100% bio-based future with a new start-up. Ugo explains, “The team produced 5 to 10 kilos of materials. Now the goal is mass production, gradually achieving 100 kilos per week.” A more sustainable space industry can be supported by the new promising composites based on biomass waste.

Similar Posts

Perhaps the molecules from the algae that wash up on the shore and slightly disrupt our vacation or those from tomato or other fruit peels will one day journey to Mars! In short, the researchers of ESA have conducted tests to boost sustainability with bio-based resins composites for space applications. In the future, the industrial waste can be reused, recycled, and repaired to take you to Mars in a spacecraft!