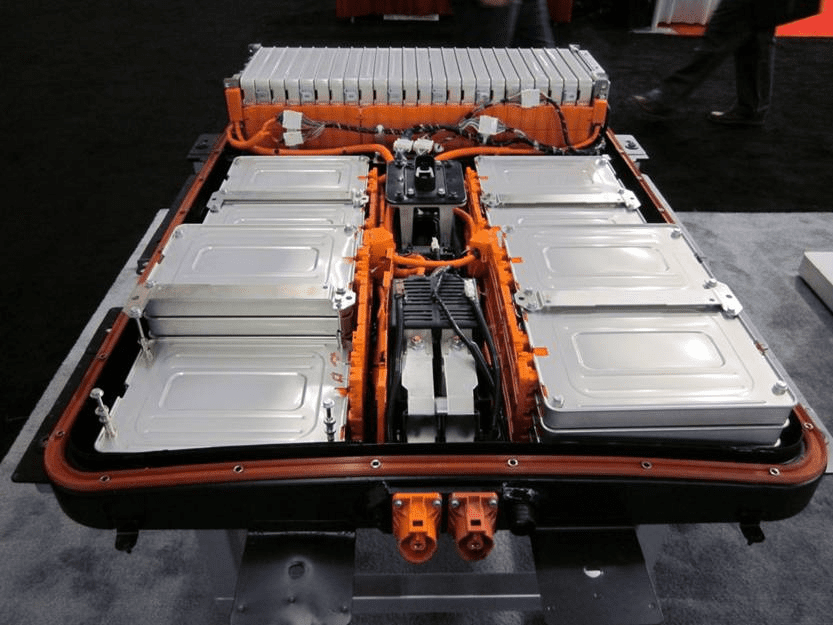

Michigan-based energy storage firm, Our Next Energy Inc. (ONE), has made significant strides in lithium iron phosphate (LFP) battery technology, narrowing the performance gap with the prevalent nickel cobalt manganese (NCM) batteries. The Aries II LFP battery pack developed by ONE is now within a 6% range and mass difference compared to the leading NCM battery. Historically, NCM batteries have dominated the electric vehicle (EV) market due to their superior energy density. LFP batteries, however, boast advantages like cost-effectiveness, durability, and the use of safer, more abundant materials.

ONE’s CEO, Mujeeb Ijaz, emphasized that their engineering advancements have positioned LFP as a viable and sustainable alternative to NCM. Since its inception in July 2020, ONE has been dedicated to bridging the energy density disparity between LFP and NCM. Their efforts have culminated in a 20-30% energy density improvement over conventional LFP systems. Chris Hughes, ONE’s chief battery engineer, highlighted the team’s holistic approach, from refining cell chemistry to reimagining the battery pack’s interior.

The inherent stability of LFP allowed for innovative pack designs, reducing the constraints typically needed for NCM chemistries. ONE’s engineering team also achieved weight reductions in the battery pack design by leveraging advanced materials. This combination of increased energy density and lightweighting means the Aries II battery can power an EV for over 350 miles on a single charge. LFP’s safety profile is superior, resisting self-oxidation even under stress, unlike the more volatile NCM.

The earth’s crust contains a substantial 5% iron, making LFP’s supply chain more robust and sustainable compared to the scarce 0.01% presence of nickel and cobalt. ONE envisions consistent pricing for LFP batteries due to iron’s abundance, especially as lithium-ion battery production scales up for renewable energy and transportation electrification. Production of the Aries II batteries is set to commence in late 2024 at ONE Circle, located in Van Buren Township, Michigan. More insights about the Aries II battery can be accessed on ONE’s official website, one.ai.

Similar Post

ONE’s overarching mission is to double EV range, utilize safer raw materials, and cultivate a localized supply chain. Benchmarking studies conducted by ONE on 28 industry battery packs validated the Aries II’s performance metrics. The company’s commitment to safety and sustainability is evident in their avoidance of nickel-cobalt chemistries, reducing battery fire risks. ONE’s future product lineup includes the Gemini battery, aiming for a remarkable 600-mile range by integrating two cell chemistries in one pack.

Collaborations with passenger-car manufacturers are underway to introduce both the Aries II and Gemini products to the automotive market. Due to surging demand from the automotive sector, ONE is contemplating an expansion of its production facility. The ONE Circle facility is projected to have the production capacity for 200,000 EVs annually by 2027, creating over 2,100 jobs.

LFP’s potential to revolutionize the EV battery market is evident in ONE’s advancements, offering a blend of safety, sustainability, and performance. The automotive industry’s shift towards LFP could reshape the future of EVs, making them more accessible and sustainable. As EV adoption accelerates globally, innovations like those from ONE will be pivotal in addressing both environmental and performance demands. With companies like ONE at the forefront, the EV industry is poised for a transformative era, balancing performance with ecological responsibility.