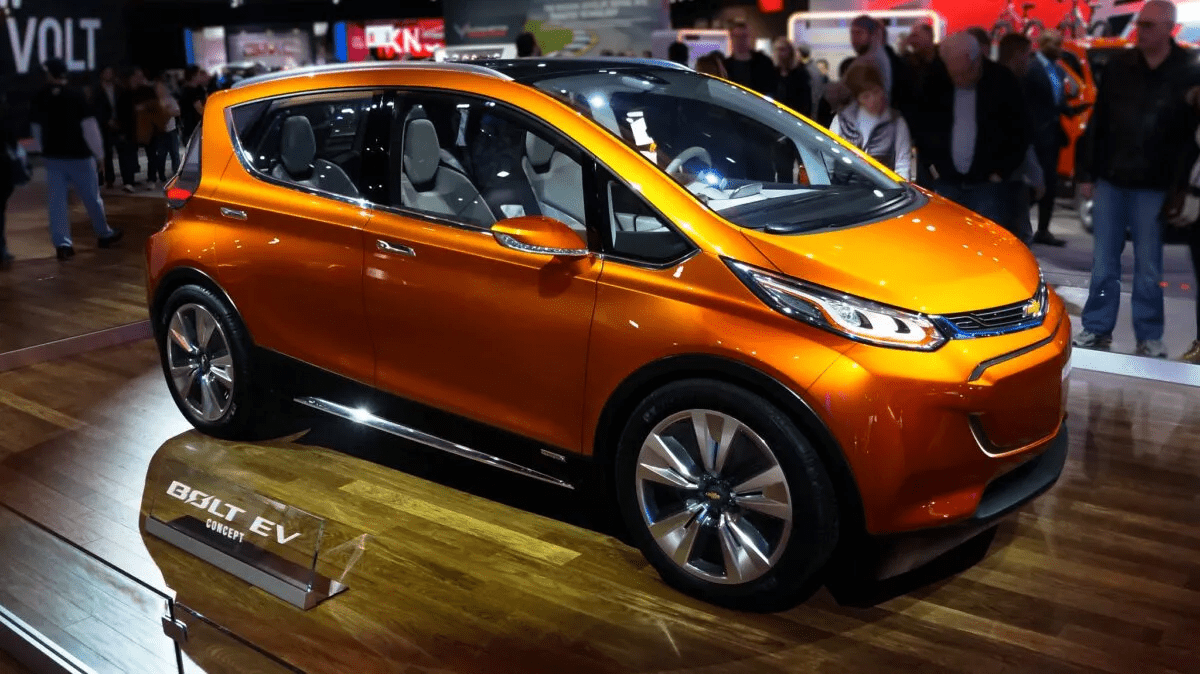

By the end of 2023, General Motors has claimed to stop production of its Chevrolet Bolt electric vehicle. The decision to end the Bolt’s production is due to GM’s transition to zero-emission production for trucks and SUVs using a new battery platform.

The Bolts discontinuation follows a larger plan to revamp the factory where it is made to assemble electric trucks. The Bolt recorded its third straight quarter of record sales in Q1 2023, selling 19,700 units.

The Bolt’s costs start at $26,500 and are eligible for a $7,500 federal tax credit. SUVs manage to cover two-thirds of overall US vehicle sales, and about 1 in 4 are pickups.

General Motors is investing $4 billion in its Orion Township Assembly Plant to produce electric pickups and SUVs using its next-generation Ultium EV platform. S&P Global Mobility projected that 10% of US vehicle sales would be EVs in 2023, with that number rising to 20% in 2025.

Cox Automotive is projecting that 45% of US vehicle sales will be EVs by 2030. GM’s Detroit-Hamtramck and Orion plants will be able to build more than 600,000 electric trucks a year by late 2024.

General Motors expects to build 400,000 EVs in North America from 2022 through mid-2024. GM battery partner LG Electronics Inc. will reimburse the automaker for $1.9 billion in costs connected to the Bolt recall.

The Bolt’s discontinuation is about profits, as pickups and SUVs make more money and people buy more of them than passenger cars. EV demand is surging, but consumers prefer the extra legroom, cargo space, and higher riding stance of big SUVs and pickups.

Mary Barra, GM of CEO, mentioned the company expects its battery plant in Warren, Ohio, to reach full capacity by year end.