Crab shell extract has been converted into a bioplastic by scientists from the Anteneo de Manila University to make optical parts known as diffraction gratings. Lasers, wavelength division multiplexing, & spectrometers use diffraction gratings (DG) to split light into its component colors in different directions. Silicone can be replaced by crab shell extract in DG to create lightweight, biodegradable, & affordable gratings.

A competitor to lithium-ion called “crab carbon” can be made by upcycling crab shell waste.

Crab shell waste or chitosan can be used as nanoparticles to treat lung cancer. Chitosan could be used to reduce waste, improve sustainability, & enhance the lives of crab fishermen & their families. Bioplastic based on chitosan can mimic fiber optics, commonly used for wired communication.

The short-term goal of the researchers is to design environmentally friendly, disposable spectrometers that can be discarded after a single use. This research has been published in the Optical Publishing Group Journal, Applied Optics. Chitosan-based bioplastic can make DG as good as the commercially available ones, according to the above study.

The promising optical properties of chitosan, such as its transparency, molding ability, & higher refractive index, make it suitable for making a spectrometer. Crab shells were obtained by the researchers from a nearby processing facility, cleaned, & dried in an oven to extract chitosan.

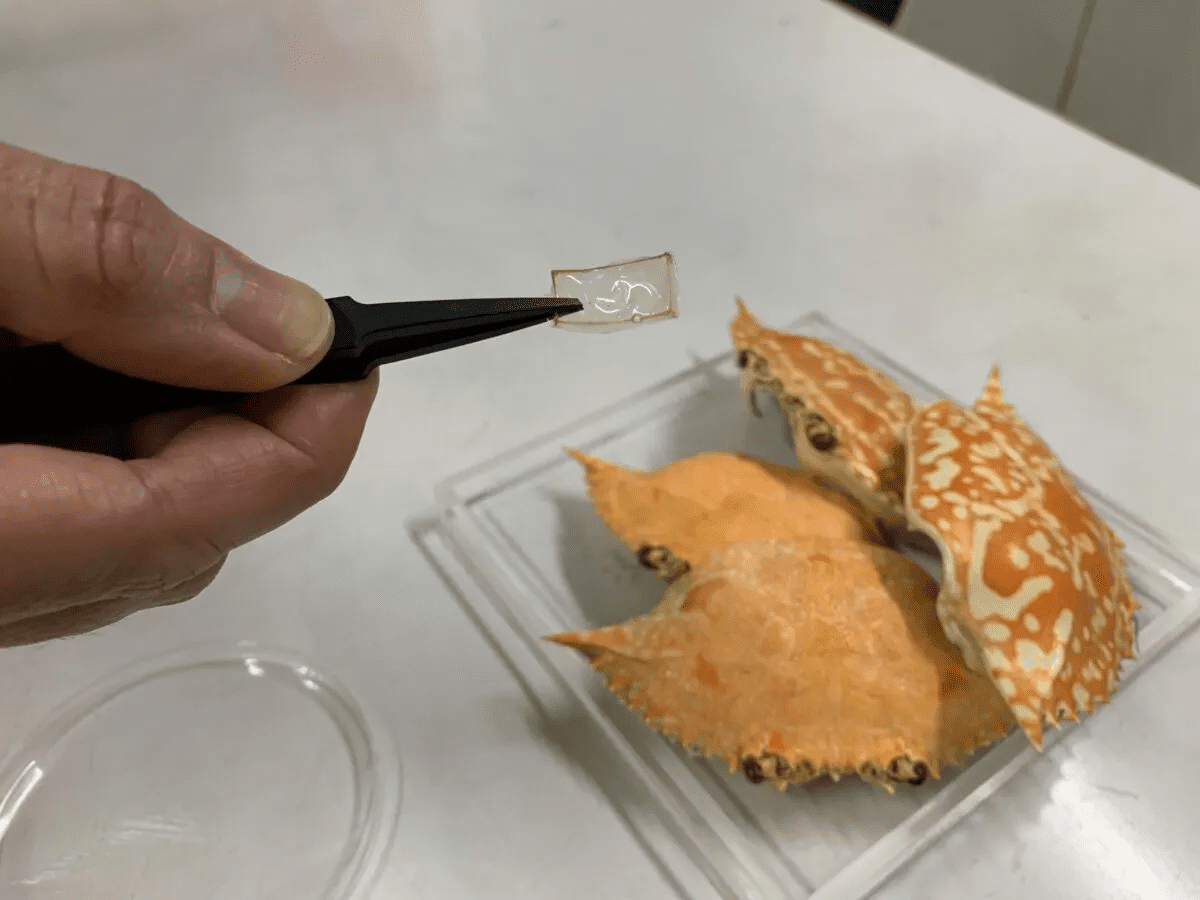

Gratings were created from chitosan by using soft lithography.

Soft lithography does not create chitosan waste, unlike subtractive methods such as laser etching. Thousands of small grooves form a part of the surface of the DG that can separate white light into its many colors. The DG made from the chitosan was tested with a laser beam & produced the desired diffraction patterns.

Lighter & less expensive spectrometers could be made by using chitosan gratings. They can be used in fieldwork spectrometers that are disposable. Chitosan-based devices would have a minimal environmental impact.