Coal from Victoria‘s Latrobe Valley in Australia, is going to be turned into “clean hydrogen” by Japan using carbon capture and storage technology. This is the start of the “commercial demonstration phase” of the Hydrogen Energy Supply Chain(HESC) project which last year delivered a world-first cargo of liquefied hydrogen to Japan on a purpose-built ship. The project will be funded by the Japanese government’s Green Innovation Fund through one of its partners, Japan Suiso Energy, that will own and operate a liquefaction and shipping facility at the Port of Hastings.

The chief executive of Japan Suiso Energy, Eiichy Harada, said : After a decade of working together with the Japanese, Australian and Victorian governments, our efforts to establish a world-first clean hydrogen energy supply chain have been rewarded. This is truly a watershed moment for our combined efforts to decarbonize global energy production. 30,000 tonnes of clean hydrogen a year will be supplied to JSE’s Port of Hastings facility by a joint venture between J-Power and Sumitomo Corporation. The project has been described by the critics as “just a new fossil fuel industry“ that would see Australia generating greenhouse gas emissions onshore while exporting a cleaner fuel.

Although neither of the two carbon storage sites identified by the project are close to being operational, yet are key to the project’s goals of producing cleaner hydrogen. Non –executive director of J-Power Latrobe Valley, Jeremy Stone, said they were “moving from start-up to scale-up phase” and commercial scale hydrogen could be a “catalyst for growth” in the Gippsland region. Stone said the HESC project could give new options for jobs in the region, as the traditional coal industry shuttered, with the Loy Yang power station set to close in 2035.

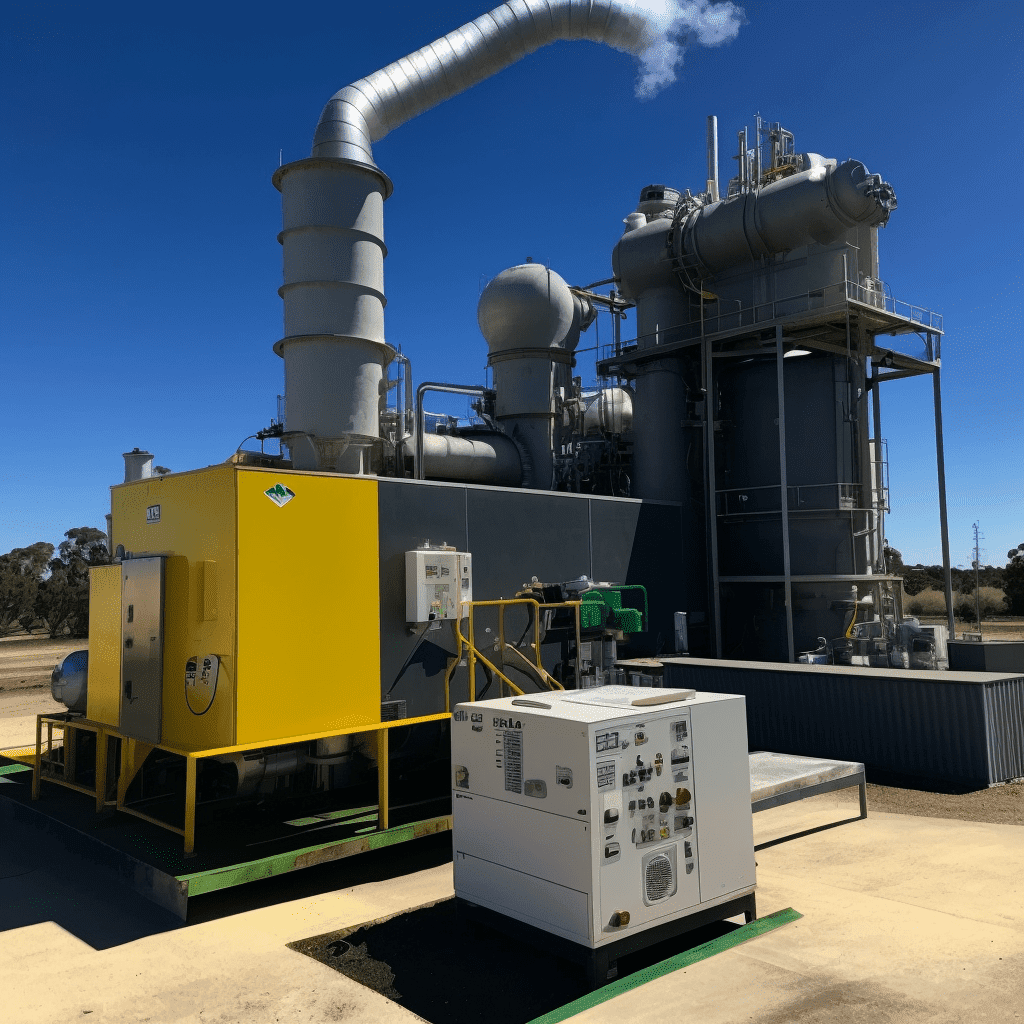

A pilot phase was completed last year by HESC, producing one tonne of hydrogen at a plant next to the Loy Yang coal power station, and then trucking it to Port of Hastings where it was condensed and loaded onto the world’s first purpose-built hydrogen container ship. According to Stone, the project would bring coal gasification technology from J-Power’s Osaki CoolGen facility to Australia which was able to capture 90% of CO2 emissions by turning the coal into synthetic gas and later extracting the hydrogen.

- Takahē Deaths in Greenstone Valley: DOC Intensifies Stoat Trapping Efforts

- Lepodisiran Injection Cuts Lipoprotein(a) by 94% in Trial

- NASA Astronauts Stranded 9 Months on ISS Due to Starliner Malfunctions

- South Atlantic Anomaly’s Expansion Poses Increased Risks to Satellites and Spacecraft Operations

- Ethiopian Airlines and Archer Aviation Partner to Launch Electric Air Taxi Network in Ethiopia

According to Stone, there were still investment decisions and government approvals to be gained, but the project was looking to produce its first hydrogen before the end of the decade. Stone said capturing and storing the CO2 “has to be part of the project” because without it “we can’t reach the carbon intensities that countries want“ from clean hydrogen.