The Goodyear Tire & Rubber Company recently revealed a demonstration tire that contains 90% sustainable materials that have been approved for road use. The demonstration tire has also passed Goodyear’s applicable regulatory testing including internal testing.

The demonstration tire had lower rolling resistance as compared to the tires made with traditional materials. A tire with lower rolling resistance will have reduced carbon footprints and better fuel savings. In January 2022, Goodyear demonstrated a sustainable tire made with 70% sustainable material. In 2023, they are working on their supply base to sell the demonstration tire created with 70% sustainable material content which can be purchased from tier sites.

However, creating a tire with 90% sustainable material content will require more time and further collaboration with the company’s base. Senior vice president of Goodyear’s Global Operations and Chief Technology Officer Chris Helsel said, “We continue to make progress toward our goal of introducing the first 100% sustainable-material tire in the industry by 2030…the past year was a pivotal one toward achieving this goal. We researched new technologies, identified opportunities for further collaboration, and utilized our team’s tenacity to not only demonstrate our capabilities to produce a 90% sustainable-material tire, but to also produce a tire with up to 70% sustainable-material content this year.”

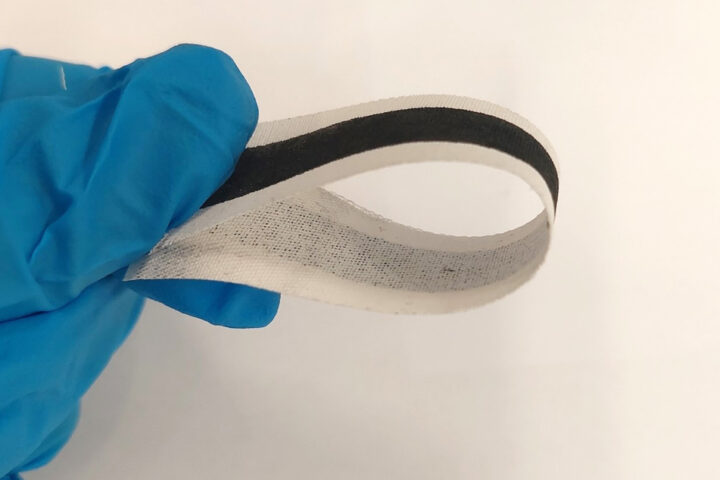

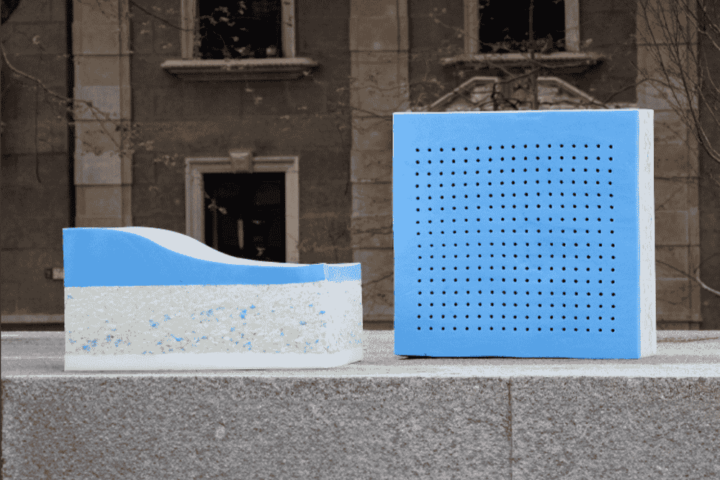

The 90% sustainable demonstration tire includes 17 feature ingredients across 12 different components. The tire’s main compound is carbon black which provides a long-lasting life. Its 90% sustainable tire features four different types of carbon black produced respectively from methane, carbon dioxide, plant-based oil, and pyrolysis oil. Carbon black technology is also helpful in reducing carbon emissions.

This demonstration tire also includes soybean oil to keep the rubber compound stable even in changing temperatures. The bio-based oils used in Goodyear’s tires reduce the company’s use of petroleum-based products. Silica is also used to improve grip and reduce fuel consumption. Resins are used to improve tire traction performance. In this demonstration tire, Goodyear has used bio-renewable pine tree resins.

- Tiger Trade Through Fishing Boats: Poaching Critically Endangered Malayan Tigers Between Malaysia and Vietnam

- National Vitamin C Day: April 4 Highlights Essential Health Benefits

- Nissan’s EV Expansion: Leaf SUV, Micra EV, Juke EV Coming by 2026

- Shoprite, Checkers Recall Heartland Foods Cereals Over Labeling Errors

- 23andMe Bankruptcy: Genetic Data of 15M Users at Risk Amid Leadership Turmoil

Goodyear has been producing RHA silica since 2018. RHA silica is naturally produced from rice husk waste residue which is a byproduct of rice most often discarded in landfills. Goodyear is confident in producing tires made with 100% sustainable materials in the future.