Scientists at the Pacific Northwest National Laboratory have discovered a record-cheap way to capture carbon dioxide as it’s emitted from power plants and factories, including the likes of iron and steel manufacturing facilities. Globally, industrial processes are responsible for 31 percent of total greenhouse gas emissions and electricity generation accounts for 27 percent, according to Bill Gates in his climate book, dwarfing the 16 percent of total greenhouse gas emissions that comes from the transportation sector.

The new technique discovered by the lab costs $39 per metric ton and is the cheapest technique for this kind of carbon capture ever reported in a peer-reviewed scientific journal. For comparison, it costs $57 per metric ton to capture carbon dioxide from a coal-fired power plant using current state-of-the-art technology.

It would be even cheaper if we could transition to 100% clean energy and didn’t have to remove carbon dioxide at all, but that’s not realistic in today’s global economy.

Just as importantly, industrial processes such as making iron, steel, cement, fertilizer, pulp and paper, and bioenergy could all reduce their carbon dioxide emissions this new technique. Scientists and entrepreneurs are working on greener ways of making cement and steel, for example, but those are not at scale.

“We have the technology to be able to capture carbon dioxide from those industrial point sources. And sitting around waiting for 20 years until we have the next-generation steel technology that doesn’t generate carbon dioxide emissions doesn’t make a lot of sense,” said Casie Davidson, who manages carbon management work at PNNL.

PNNL’s technique removes carbon dioxide at the source, rather than sucking it out of the air. The technique of vacuuming up existing CO2 out of the air is known as direct carbon capture, and is exemplified by the Swiss company Climeworks.

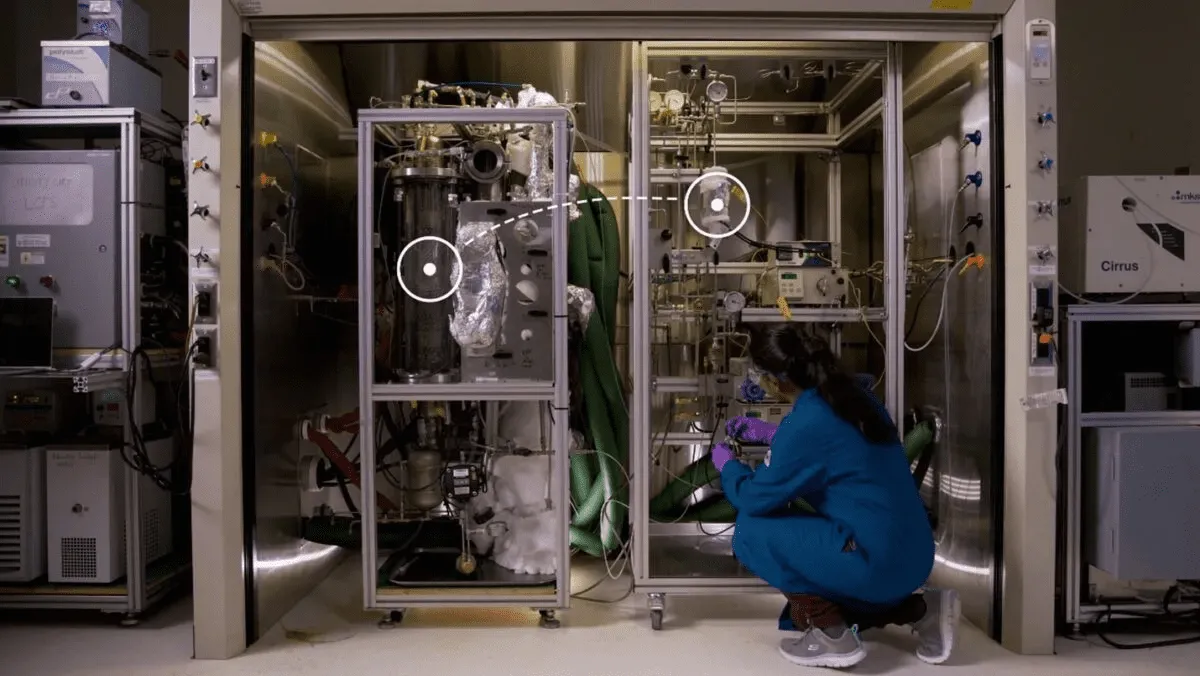

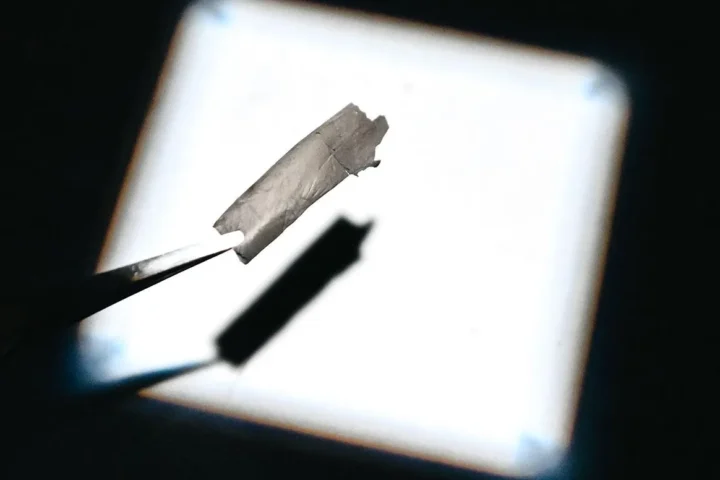

Scientists at Pacific Northwest National Laboratory (PNNL) have developed a new carbon capture method that uses 2% water, compared to as much as 70% in previous technologies. The process pumps 4 million litres of liquid per hour and is cheaper because it takes less energy to boil a smaller amount of water. The liquid is heated until the CO2 is released as a gas, compressed for transportation and the remaining liquid is cooled and sent back to the first stage of the process. The system is large and requires a significant amount of energy from the power plant, taking up 30% of the energy generated. However, it removes 90% of the carbon dioxide and ultimately results in a net reduction of 87% on a per-megawatt net power generation basis.

While a small percentage of carbon dioxide can be used to make products like methanol, the majority will need to be stored underground. Todd Schaef, a scientist at PNNL, explains that the amount of carbon dioxide that needs to be sequestered is “staggering.” Sequestration is generally cheaper than capturing carbon dioxide in the first place. In his research, Schaef has injected carbon dioxide into the subsurface of the Earth and found that it reacts with the rock and converts to a carbonate, permanently storing it underground. This process is considered to be stable on geologic timescales. Some climate change activists argue that carbon capture technology delays the necessary transition to reducing and eliminating fossil-fuel emissions, but Schaef believes it is necessary to sequester the carbon dioxide that has already been emitted and will continue to be emitted until a transition to more climate-conscious processes can be made.