In an era where methane emissions pose a severe climate threat – with warming effects 84 times more potent than CO2 over a 20-year timescale – MIT spinout Emvolon has engineered a practical solution by repurposing automotive engines into modular chemical plants. This technical advancement addresses two pressing environmental challenges: distributed methane emissions and the decarbonization needs of heavy transport sectors.

The company’s approach transforms methane gas into green methanol and ammonia at the source, eliminating costly transportation infrastructure. Each compact unit, housed within a 40-foot shipping container, processes 300,000 standard cubic feet of methane daily, yielding 8 tons of methanol.

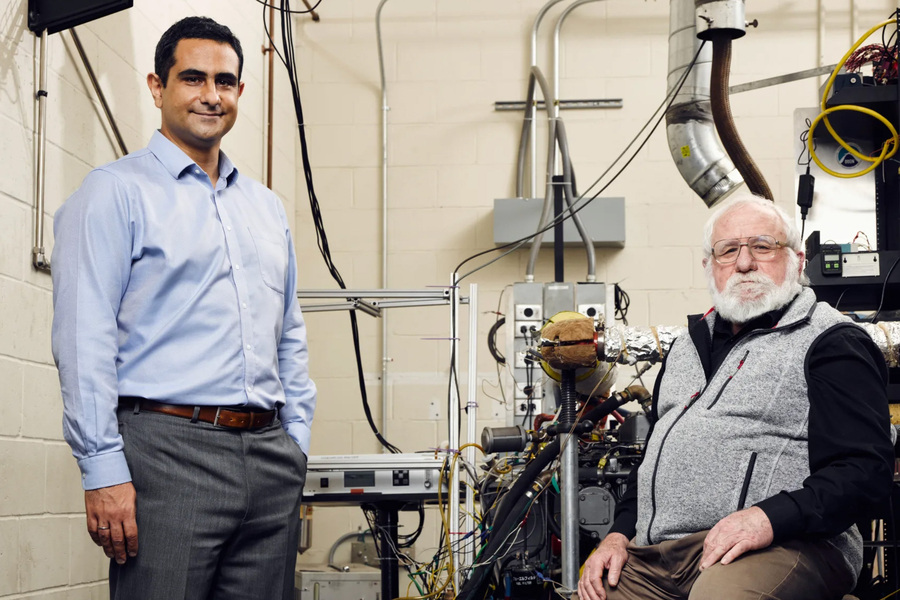

“You can’t electrify a large ship or plane — you have to use a high-energy-density, low-carbon-footprint, low-cost liquid fuel,” states Emmanuel Kasseris, Emvolon’s co-founder and CEO. The technology continues to develop as it moves from laboratory to commercial deployment.

Technical Innovation Meets Practical Challenges

The system’s core operates on a modified automotive engine running “fuel rich” – utilizing more fuel than air for incomplete combustion. This process creates carbon monoxide and hydrogen as building blocks for chemical synthesis. The engineering combines standard automotive technology adapted for chemical synthesis.

Emvolon’s facility in Woburn, Massachusetts currently produces six barrels of green methanol daily. A recent partnership with Montauk Renewables will test the technology’s commercial viability at a Texas landfill, targeting initial production of 15,000 gallons annually, scaling to 2.5 million gallons.

Economic Viability and Market Dynamics

The modular approach requires investments of $1-10 million per unit, with deployment timeframes of weeks rather than years. This contrasts sharply with traditional chemical plants demanding hundreds of millions in capital and multi-year construction cycles.

Leslie Bromberg, principal research engineer at MIT’s Plasma Science and Fusion Center, initiated this concept through Department of Energy-funded validation. The technology has since evolved from a “crazy idea” to a practical solution for methane conversion.

Environmental Impact and Industry Applications

Current data indicates methane contributes to approximately 15% of global greenhouse gas emissions from hard-to-abate sectors. Another 15% originates from distributed sources like landfills and oil wells. Emvolon’s technology targets both issues simultaneously.

The shipping industry’s transition to green methanol presents an immediate market opportunity. The technology also shows promise for producing sustainable aviation fuel and decarbonizing fertilizer production through ammonia synthesis.

More Stories

Future Prospects and Applications

The Department of Energy has extended support to adapt the technology for clean liquid fuel production using renewable energy sources. The system builds on proven automotive engine technology, adapted for chemical synthesis.

The scalability from single-cylinder prototypes to multi-cylinder configurations follows established engineering principles. As Kasseris notes, “If it works in a single cylinder, we know it will work in a multicylinder engine. It’s just engineering.”

Emvolon’s innovation offers a new approach to emissions reduction while producing valuable chemical products. The commercial deployment at the Texas landfill marks an important step in implementing this technology for sustainable chemical manufacturing.