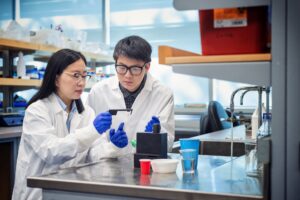

The age-old challenge of cooling without harming our planet just got a major boost at Hong Kong University of Science and Technology (HKUST). A team of engineers has cracked a technical barrier in elastocaloric cooling, pushing the temperature lift to 75K – a 24.4K increase from the previous record of 50.6K.

Here’s the nitty-gritty: The cooling system uses shape memory alloys (SMAs) made of nickel-titanium (NiTi) that undergo phase transitions to absorb or release heat. The team stacked three different NiTi alloys together, each tuned to work at specific temperatures – cold end, middle, and hot end. By matching each alloy’s phase transition sweet spot to its working temperature, they expanded the system’s superelastic temperature window beyond 100K.

The numbers tell the story: While traditional vapor compression systems gulp down 7-10% of global energy, this new system boosts cooling efficiency by 48%. “We’re hitting 75K temperature lift on the water side,” says Prof. SUN Qingping, who led the research with Prof. YAO Shuhuai. That shatters the previous world record of 50.6K.

For those interested in cooling technology, here’s where it gets interesting: The system completely ditches those nasty high-GWP (Global Warming Potential) refrigerants. Instead, it uses 100% recyclable SMAs (Shape Memory Alloys) that work through latent heat in cyclic phase transitions. No greenhouse gases, no chemical leaks, just pure thermodynamic elegance.

More Stories

The timing is crucial. Space cooling and heating account for 20% of the world’s total electricity consumption. According to industry estimates, they are projected to become the second-largest source of global electricity demand by 2050. The research work was conducted by Postdoctoral Research Associate Dr. ZHOU Guoan (first author), PhD student LI Zexi, PhD graduates ZHU Yuxiang and HUA Peng.

But let’s talk real-world challenges: Scaling this tech means solving manufacturing puzzles and figuring out how to integrate it with existing HVAC systems. The team’s got patents and publications in Nature Energy under their belt, but they’re not stopping there. Their research breakthrough was published in Nature Energy, and the team has secured multiple patents. The research team plans to further develop high-performance shape memory alloys and devices for sub-zero elastocaloric cooling and high-temperature heat pumping applications.

The tech specs that matter: Zero greenhouse gas emissions, 100% material recyclability, and a superelastic temperature window stretching beyond 100K. For context, the International Energy Agency projects cooling-related electricity demand will triple by 2050 without tech breakthroughs like this.

Prof. Sun puts it plainly: “With materials science and mechanical engineering advancing, elastocaloric refrigeration can feed the huge worldwide refrigeration market while fighting global warming.” The team’s already eyeing ways to optimize material properties for even better energy efficiency.