Worcestershire’s streets are getting an eco-friendly makeover with RECOFOAM®, an innovative material that’s changing how we build our footways. As someone who’s watched sustainable construction evolve over the years, I can tell you – this is practical environmental action at work.

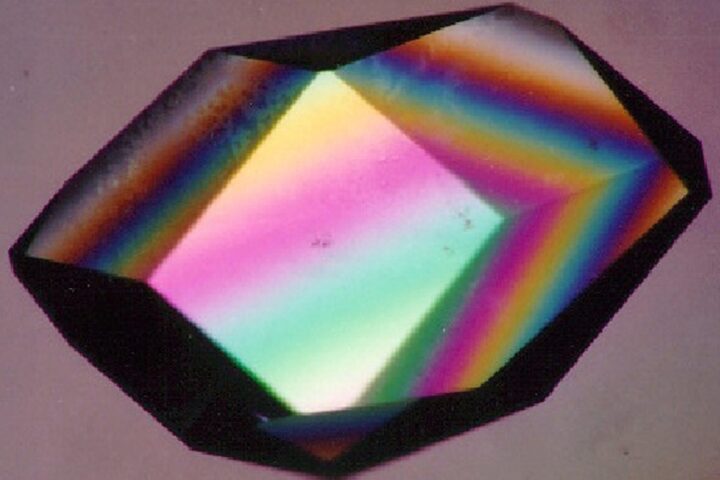

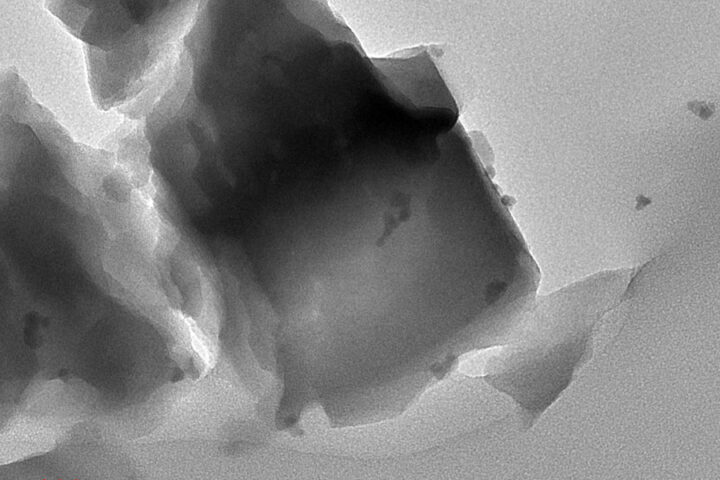

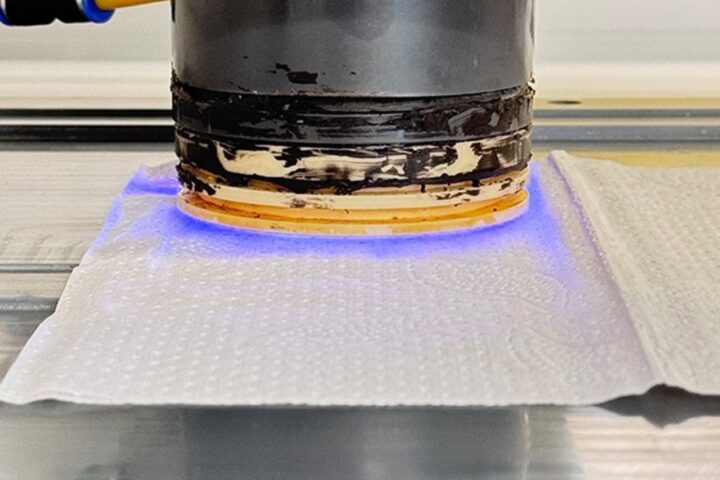

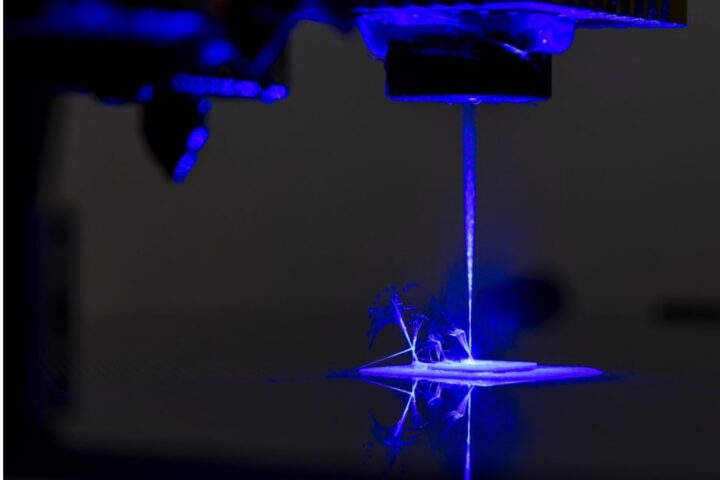

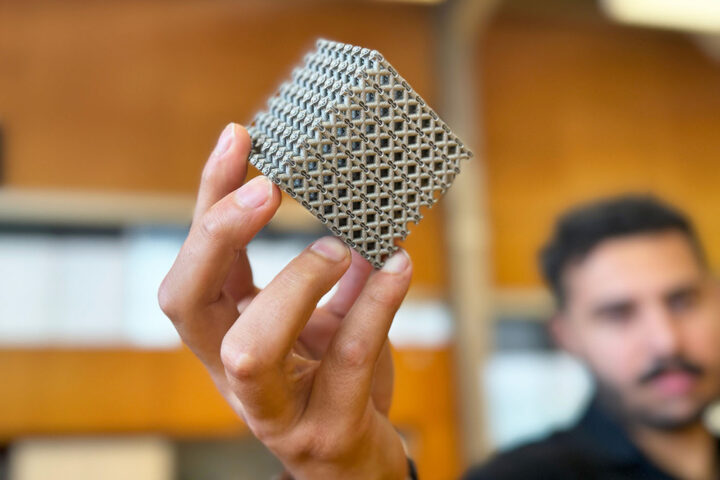

Let’s get into the nitty-gritty. RECOFOAM® is a binder course material that Ringway, the county council’s contractor, produces using foamed bitumen technology. The technical specs are impressive: it’s made with 97% recycled materials and slashes carbon emissions by 70% per tonne compared to traditional hot mix asphalt. For my fellow material science enthusiasts, the process involves repurposing hardcore waste from existing footway projects, which gets crushed and blended with foamed bitumen to create a durable surface.

The environmental impact data speaks volumes. In 2023, Ringway manufactured 8,522 tonnes of RECOFOAM® for footway reconstruction. This reduced emissions to 144,874 kg CO₂e – a 74% reduction from the 553,930 kg CO₂e that conventional materials would have generated. For context, that’s equivalent to taking dozens of cars off the road for a year.

What makes this particularly clever from an architectural perspective is how it handles problematic materials. The process safely incorporates asphalt waste containing coal tar, preventing these hazardous materials from ending up in landfills. It’s a prime example of circular economy principles in infrastructure development.

Councillor Emma Stokes, Worcestershire’s cabinet member for the environment, shared her perspective: “Our use of RECOFOAM® represents a significant step forward and we are proud to use it as an excellent example of sustainable footway infrastructure. By incorporating recycled materials and reducing our carbon footprint, we are protecting our environment and setting a new standard for roadworks. This achievement demonstrates our dedication to creating a cleaner, greener Worcestershire for future generations.”

The implementation goes beyond environmental benefits. The single-layer application reduces construction time and minimizes waste, though contractors need to consider weather conditions during application for optimal durability. The material has proven so effective that it’s now become the standard for footway reconstructions across Worcestershire.

Similar Posts

This initiative is part of Worcestershire’s broader £8 million investment in footway improvements. The council’s collaboration with Ringway extends to other green initiatives, including the transition to electric vehicles and high-diversion waste practices. They’ve even installed beehives at their depots, showing a commitment to biodiversity alongside infrastructure development.

For residents, this means smoother, more sustainable footways without compromising on quality. The council and Ringway maintain open communication about ongoing works and their environmental benefits, ensuring community engagement throughout the process.

The technical success of RECOFOAM® in Worcestershire offers valuable insights for other UK regions looking to adopt sustainable infrastructure solutions. As cities worldwide grapple with reducing their environmental impact, these practical applications of circular economy principles in public infrastructure demonstrate viable paths forward.