A transformative initiative in renewable energy innovation is initiated by the PRIME-Fuel project. The new fuel is developed by the University of Houston (UH) and SRI International. The project focuses on creating a microreactor to convert CO2 into methanol using renewable energy sources like wind and solar. ARPA-E’s GREENWELLS program has supported the project aimed at making sustainable liquid fuel production affordable and scalable. It addresses critical needs in clean energy transition and storage.

SRI’s proprietary Co-Extrusion printing technology and advanced control algorithms to enable methanol production are used by PRIME-Fuel. This can be used even during renewable energy dips as low as 5% capacity. Cost-effective, distributed methanol production from CO2, water, and renewable energy impact is the focus of the microreactor design. A fundamental chemical building block, methanol demonstrates significant versatility with promising applications spanning packaging solutions and energy storage systems. Its adaptable nature positions it as a key component in various industrial processes. Reducing carbon emissions by over 88% when scaled to large facilities is the aim of the project. Thus it contributes to US climate goals.

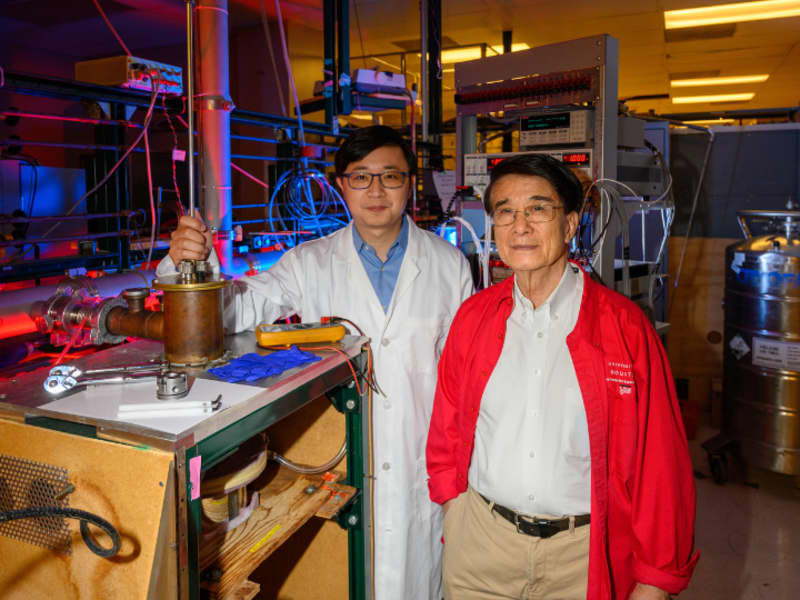

Strong academic-industry collaboration is exemplified by this project. Expertise in catalyst development and microreactor modeling are contributed by UH researchers like Praveen Bollini and Vemuri Balakotaiah. This collaboration is facilitated by alumni connections. It showcases the impact of academic networks. Although the initial focus is on methanol, the microreactor platform is adaptable for other energy carriers and chemicals. It broadens its relevance across energy and chemical industries.

Similar Post:

US Secretary of Energy Jennifer M. Granholm said in ARPA-Express release: “Renewable-to-liquids fuel production has the potential to boost the utility of renewable energy all while helping to lay the groundwork for the Biden-Harris Administration’s goals of creating a clean energy economy.”

Using cheaper electricity from sources like wind and solar lower production costs. Rahul Pandey, senior scientist with SRI and principal investigator on the project said, “We believe that PRIME-Fuel will play a critical role in the transition to sustainable energy solutions.”

During the three-year project, the researchers will develop a microreactor prototype capable of producing 30 MJe/day of methanol while meeting energy efficiency and process yield targets. Pandey said, “Right now, we are aiming to produce methanol, but this technology can actually be applied to a much broader set of energy carriers and chemicals.”

He added, “After successfully completing the prototype, we plan to scale up and commercialize the technology in collaboration with SRI and other industrial partners.” According to him, while it is challenging to provide an exact timeline for market availability, a reasonable expectation would be around five years.

Praveen Bollini, associate Professor of chemical engineering at UH says, “The technology developed here will provide a means for the distributed, low-cost production of methanol using stranded renewable sources of energy, including those in underdeveloped countries.”

SRI and University of Houston are to receive $3.6M to develop a microreactor to convert CO2 to methanol using renewable energy. This breakthrough will transform technology, paving the way for the production of sustainable fuel. This is the PRIME-Fuel project.